Heatsink Clip Load Methodology

C.2.2 Typical Test Equipment

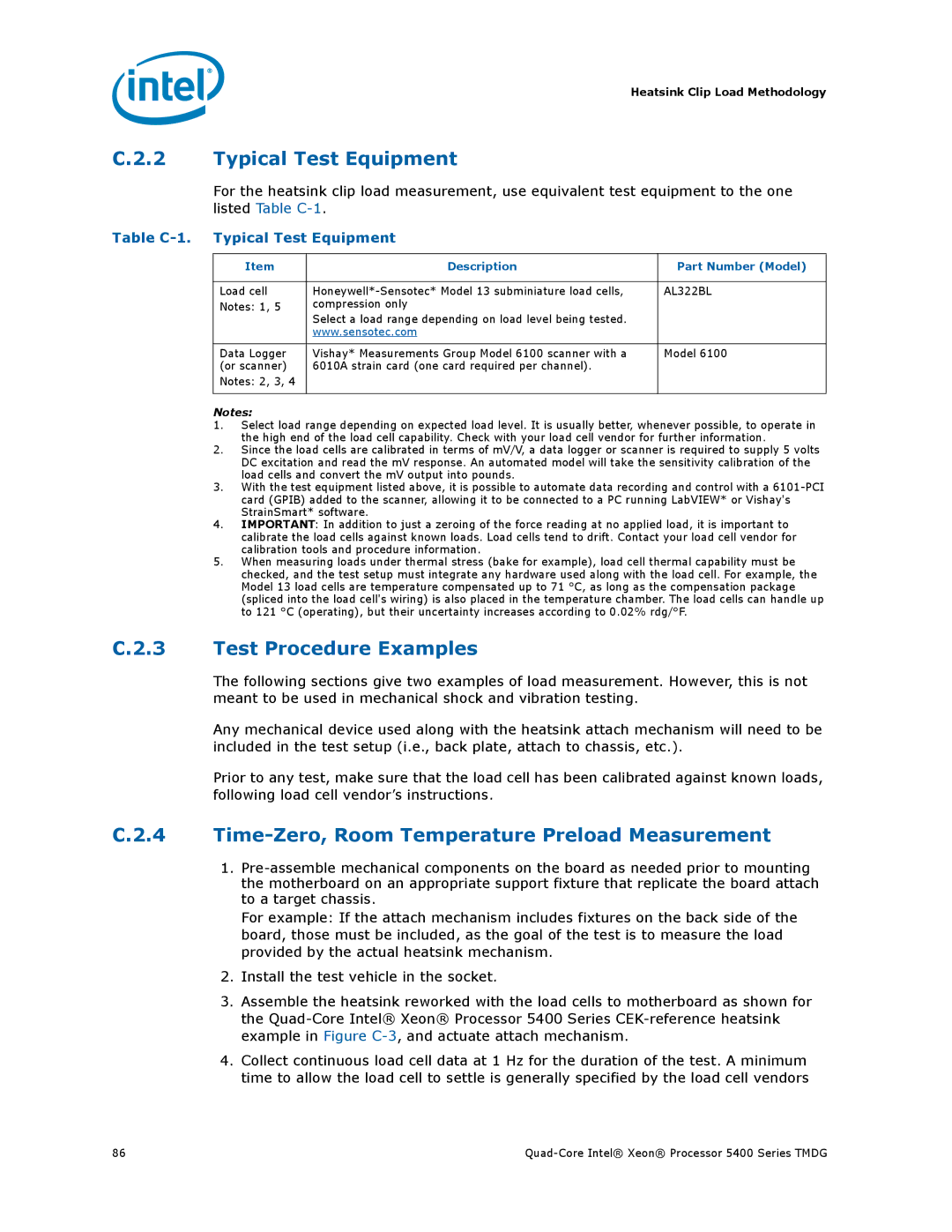

For the heatsink clip load measurement, use equivalent test equipment to the one listed Table

Table C-1. Typical Test Equipment

Item | Description | Part Number (Model) |

|

|

|

Load cell | AL322BL | |

Notes: 1, 5 | compression only |

|

| Select a load range depending on load level being tested. |

|

| www.sensotec.com |

|

|

|

|

Data Logger | Vishay* Measurements Group Model 6100 scanner with a | Model 6100 |

(or scanner) | 6010A strain card (one card required per channel). |

|

Notes: 2, 3, 4 |

|

|

|

|

|

Notes:

1.Select load range depending on expected load level. It is usually better, whenever possible, to operate in the high end of the load cell capability. Check with your load cell vendor for further information.

2.Since the load cells are calibrated in terms of mV/V, a data logger or scanner is required to supply 5 volts DC excitation and read the mV response. An automated model will take the sensitivity calibration of the load cells and convert the mV output into pounds.

3.With the test equipment listed above, it is possible to automate data recording and control with a

4.IMPORTANT: In addition to just a zeroing of the force reading at no applied load, it is important to calibrate the load cells against known loads. Load cells tend to drift. Contact your load cell vendor for calibration tools and procedure information.

5.When measuring loads under thermal stress (bake for example), load cell thermal capability must be checked, and the test setup must integrate any hardware used along with the load cell. For example, the Model 13 load cells are temperature compensated up to 71 °C, as long as the compensation package (spliced into the load cell's wiring) is also placed in the temperature chamber. The load cells can handle up to 121 °C (operating), but their uncertainty increases according to 0.02% rdg/°F.

C.2.3 Test Procedure Examples

The following sections give two examples of load measurement. However, this is not meant to be used in mechanical shock and vibration testing.

Any mechanical device used along with the heatsink attach mechanism will need to be included in the test setup (i.e., back plate, attach to chassis, etc.).

Prior to any test, make sure that the load cell has been calibrated against known loads, following load cell vendor’s instructions.

C.2.4 Time-Zero, Room Temperature Preload Measurement

1.

For example: If the attach mechanism includes fixtures on the back side of the board, those must be included, as the goal of the test is to measure the load provided by the actual heatsink mechanism.

2.Install the test vehicle in the socket.

3.Assemble the heatsink reworked with the load cells to motherboard as shown for the

4.Collect continuous load cell data at 1 Hz for the duration of the test. A minimum time to allow the load cell to settle is generally specified by the load cell vendors

86 |

|