ODA/OEL/INT

Preface

Contents

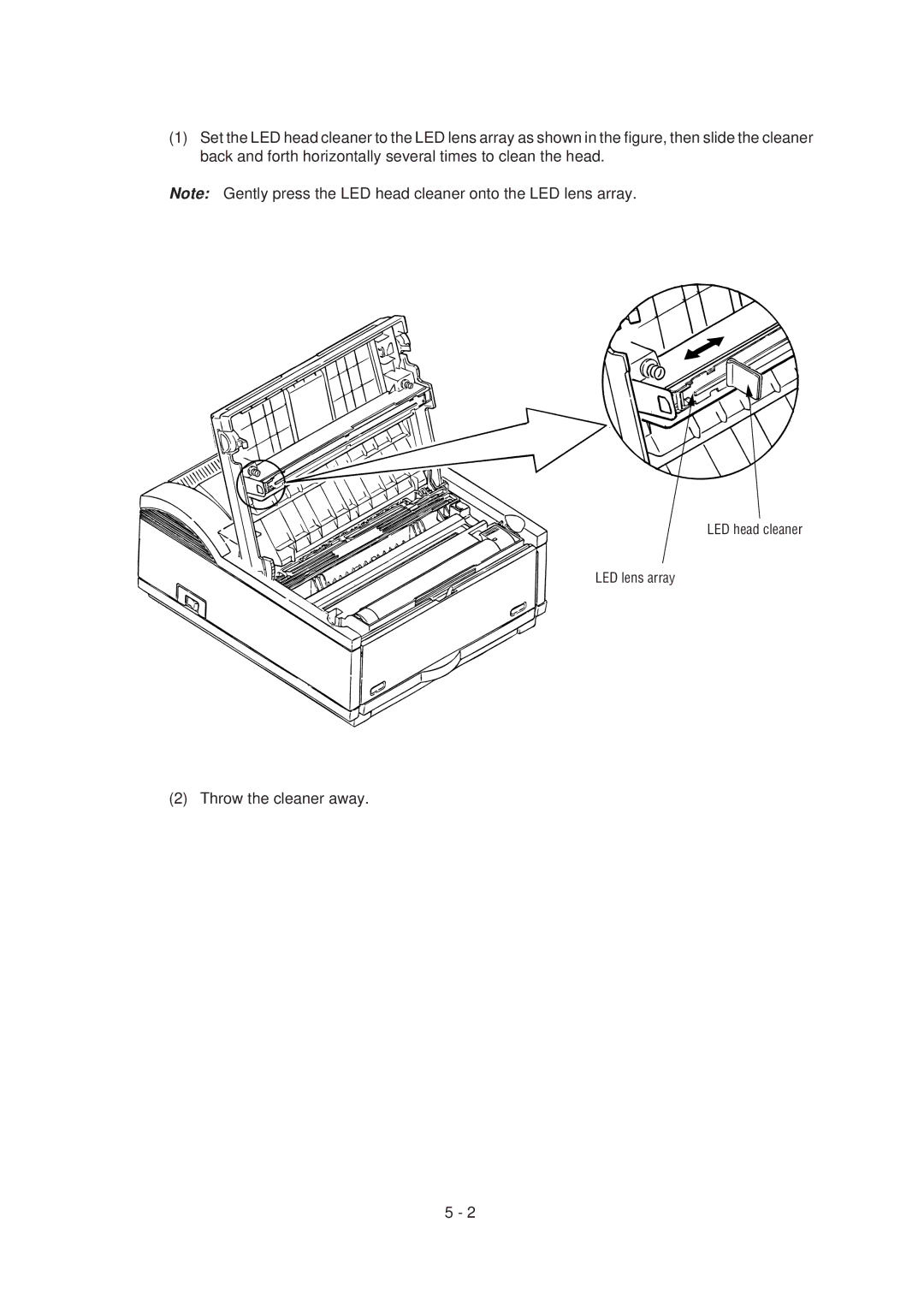

Cleaning of LED Lens Array

Adjustment

Adjustment When Replacing a Part

Periodical Replacement Parts Cleaning

Configuration

Operator Panel Okipage 6ex Only Engine Unit

System Configuration

Operator panel assy Upper cover

Legal/Universal cassette Cassette cover

High Capacity Second Paper Feeder Multi-Purpose Feeder

Specification

Page

Safety Standards

Page

Portuguese

English

French

Spanish

Operation Description

Operation Description

Okipage 6e Block Diagram

Okipage 6ex Block Diagram

Control Board

Eeprom

Simm

PS Board Okipage 6ex option

ROM

SCC

RAM Board Okipage 6e/6ex option

RAM Board Block Diagram

Use

Hopping operation to feeding operation

Sensor layout diagram is shown in Figure

Electrophotographic Process

Heat roller LED head Developing roller

Page

Page

Paper Eject Roller

PRINT-N PRDY-N DM-ON-N RM-ON Insns OUTSNS-N

Page

Paper Registration roller Hopping roller

Image drum Paper

Power

CTL CGL

Image drum Surface potential 100 Charged part

300V Developing roller

Page

Image drum Paper Transfer roller Power supply

Page

Image drum Cleaning roller Power supply Transfer roller

Paper Jam Detection

Error Cause of error

Paper Feed Timing Chart

Unit mm Paper Length List

Paper Feed Check List

Cover Open

Stirring Gear Section Stirring Bar

Toner LOW state

Toner Full state

Parts Replacement

Precautions for Parts Replacement

Parts Number

Printer, etc

4YA4046-1722G1

Lower base unit

Upper cover unit

Base unit

Printer unit

Page

Page

Page

Page

CN2

CN3

CN3 Okipage 6e

Page

Idle gear Reduction gear Clamp lever

Page

Page

Page

Latch

Page

Page

Paper sensor Inlet sensor

Page

Page

Put into the post Put into the groove

View a

L6A

9View a

Page

Page

Page

Adjustment

Adjustment Okipage 6e

Shows the Main Menu Dialog

Page

Page

Page

Page

Page

Page

Page

HIPER-W ENABLE/DISABLE Sidm ENABLE/DISABLE

Adjustment Okipage 6ex

Page

Parts Required Adjustment LED head LED head drive time

Luminous intensity Drive time parameter

73000123400101100

1224G2

401326

403579

065 ~

ENG MNT

Xxxxxx

Page

Periodical Maintenance

Parts are to be replaced periodically as specified below

Periodical Replacement Parts

Throw the cleaner away

Troubleshooting Procedures

Troubleshooting Tips

Undefined

OFF Blinking

Problems Problems indicated by error message

Category

Contd Category

Contd Category

Contd Category

Contd Category

Contd Category

Trouble or status Remedy Daily status Manual Paper

Procedure, use the following

If the normal operation is not

Remedial actions

Eeprom

PCB

Cover

Feed JAM

By the second line message is Manual tray

Second line message to the first Tray

Lines tray is requested Tray Tray 1, Tray 2, Feeder

Manual loading of paper indicated Load the requested paper

For printing on Error display

Recover key to release

Change the setting of the host

Because it received too much data Recover key to release

Printer is processing data

Printer is in the middle of a job

Printer is printing a

Printed during self-test Current menu setting is being

When the number of copies being

Printed is two or more, the number

This message is displayed when

This message is displayed during

Post Script mode only Normal operation

For OKIPAGE6ex, HP 4 mode

Printer goes back to on-line

Refer to the User’s Manual

Trouble or status Remedy Daily status

Job processing. The remainder

This message will appear when Host

Trouble

PCB?

Low-voltage Power Supply Block Diagram

Initial

Izing

ON-LINE

Power supply board

Connect connector CN3 properly

Page

Page

Page

Toner Inlet Paper End sensor Registration roller Sensor

Fusing unit is mounted in the printer see -4 contact F ?

Adjust the contact

Replace the Main Control PCB or power supply board

Page

Cyclical defect -3, E Print voids

Page

Page

Page

Cyclic error

Page

Page

Page

Heater

Contacts

Contact Power supply board

Wiring Diagram

Interconnect Signal Diagram

CN2 CN1 CN7

Centronics Parallel I/F

CN8 CN3

Control Board Okipage 6ex L6A

Control Board Okipage 6e L5C or L5D-PCB Okipage 6ex L6A-PCB

Power Supply Board PS Board LQ8A-2 Okipage 6ex

CN1 Pin Assignment To Fan motor

CN2 Pin Assignment To Drum motor

Excitation sequence

CN3 Pin Assignment To Regist motor

CN4 Pin Assignment To LED head Okipage 6e

HEAD1 & HEAD2 Pin Assignment To LED head Okipage 6ex

CN6 Pin Assignment To Option feeder

Power Pin Assignment To power supply/sensor board

CN8 Pin Assignment Centro Parallel

SCRREO-P

CN11 Pin Assignment To Option board and PS board

PS Board OKIPAGE6ex CN1 Pin Assignment To LocalTalk RS422

SCRREQ-P

PS Board OKIPAGE6ex CN2 Pin Assignment To Main Control PCB

Circuit Diagram Illustration

Unit Circuit Diagram Illustration

SP2

Option RAM Board LQME-PCB

SP1 SP2

Parts List

Lower Base Unit

USE

Lower Base Unit Name/Rating

Upper cover unit

Upper cover unit Name/Rating

Base unit

L6A

Base unit Name/Rating

Appendix a Centronics Parallel Interface

ECP

Table of parallel I/F signals

Sending circuit

Acknowledge Busy

Fault

Busy

Parallel Data

Busy Select

ON-LINE SW Busy Select

Parallel I/F is displayed on the LCD

Interface Parameter Setting Okipage 6ex

Key, after selecting the display

OFF-LINE HP4

ON-LINE HP4

Sync

Output

Input

Transmitting circuit 26LS32 or equivalent

Differential Input

PowerSave

OFF-LINE Adobe PS

Localtk

Activ

Key, 8 times

RS422 I/F parameter setting

RS422

Keep

None

Databits

Bits

Parity

User Maintenance Mode

Appendix C Diagnostics Test Maintenance Modes

Disable

Menu Reset

Enable

ON-LINE Resetng HP4

System Maintenance Mode

CNT

PRT Disable Enable

HIPER-W Enable Sidm

SYS MNT

Engine Maintenance Mode

Page

Narrow * Full Type 1 Type 2D4

Engine maintenance mode menu system

Test

T2 TBL

EF TBL

WT TBL

Factory User Setting Operation

OL610e/610ex OKIPAGE6e OL600e/600ex OL400W OKIPAGE6ex

Purpose of the Maintenance Utility

Maintenance Utility Functions

OKIPAGE4W

Software Configuration

Main Menu Dialog

Engine Menu Group

LED Head Drive Time

LED Head Width Okipage 6e

Count print

Head type Okipage 6ex

Engine Counter Group

Normal Status

Status Monitor

Warming Up

Jam & Size Error

Unrecoverable Error

XXX.BIN

Test Print Button

XXX.HBP

XXX.PCL

Option Button

About Button

Reload Button

Exit Button

Option Menu Dialog

Reset Engine Button

Eeprom Upload Button

Eeprom Download Button

RAM Check Button Not supported Set ID button

Setup Dialog

Appendix E Multi-Purpose Feeder Maintenance

Preface

LCD Status Message List

Interconnection Diagram PCB Layout

Functions External View and Component Names

General Mechanism Hopper Mechanism

Functions

General Mechanism

Precautions Concerning Parts Replacement

Service Tools

This section describes the layout of the main components

Parts Replacement Methods

Page

Screwdriver Lock

Sensor Plate

Page

Page

Sensor Lever Roller-B

Precautions Prior to the Troubleshooting

OEL/INT

Status message display Ready LED display

Frequently, to through

When the problem occurs

Troubleshooting

Paper Input Jam Paper Feed Jam Paper size error

YES

Interconnection Diagram

OPTSD-P

OVP OVL

OLEV-11 PCB

Multi-Purpose Feeder

OEL / INT

OLEV-PCB

ODA

3YS4011-3141P1 56631201

Appendix F High Capacity Second Paper Feeder Maintenance

Preface

General Mechanicsm Hopper Mechanism

Hopping Roller Shaft Assembly and One-way Clutch Gear

External View and Component Names

General Mechanicsm

Parts Replacement

Service Tools

Parts Layout

Parts Replacement Methods

Page

Page

Page

Troubleshooting

OEL/INT

Logo print Status message display Ready LED display

From High Capacity Feeder

State of the High Second paper Feeder

Paper Feeder Second Tray Paper Out

Replace the hopping roller shaft assy or paper cassette

Is the connector cable being connected properly?

Connect the connector cable properly

Replace the sensor plate. Inlet

FG FG

3 4 5 6 7 8 9

OLEV-12 PCB

High Capacity Second Paper Feeder

High Capacity Paper Feeder

OKI Data Corporation