2.8Toner Low Detection

•Device

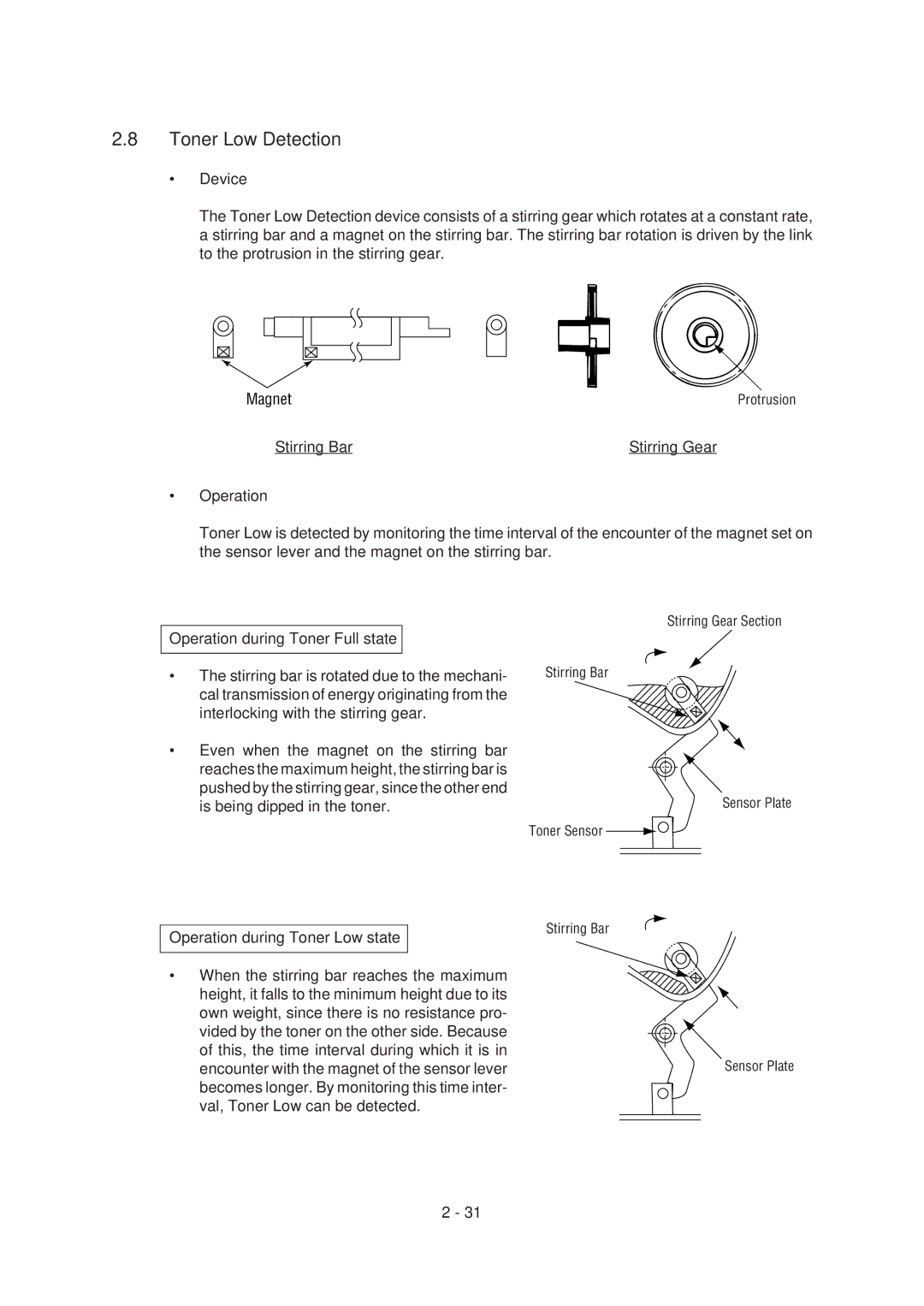

The Toner Low Detection device consists of a stirring gear which rotates at a constant rate, a stirring bar and a magnet on the stirring bar. The stirring bar rotation is driven by the link to the protrusion in the stirring gear.

Magnet | Protrusion |

Stirring Bar | Stirring Gear |

•Operation

Toner Low is detected by monitoring the time interval of the encounter of the magnet set on the sensor lever and the magnet on the stirring bar.

Operation during Toner Full state

•The stirring bar is rotated due to the mechani- cal transmission of energy originating from the interlocking with the stirring gear.

Stirring Gear Section

Stirring Bar

•Even when the magnet on the stirring bar reaches the maximum height, the stirring bar is pushed by the stirring gear, since the other end is being dipped in the toner.

Operation during Toner Low state

•When the stirring bar reaches the maximum height, it falls to the minimum height due to its own weight, since there is no resistance pro- vided by the toner on the other side. Because of this, the time interval during which it is in encounter with the magnet of the sensor lever becomes longer. By monitoring this time inter- val, Toner Low can be detected.

Sensor Plate

Toner Sensor ![]()

Stirring Bar

Sensor Plate

2 - 31