General Machine Cleaning

The machine should be cleaned every eight hours of use or as needed. With the exception of the print heads and the optical sensors, the machine can be cleaned using an alcohol base solution. Simply apply a liberal amount of alcohol to a clean rag and wipe down the machine components starting at the unwind and ending at the stacker.

Printheads

Refer to the Automated Print Head and Manual Manifold Cleaning sections for cleaning the print heads.

NOTE: The print head guards can be cleaning with alcohol.

Optical Sensors

When an erroneous interlock condition occurs or print registration in reference to a sense mark becomes inconsistent or erratic - a sensor may need to be cleaned. Always use clean supplies when cleaning sensors. Never use anything abrasive on any of the sensors. Never use an alcohol based solution on any of the sensors. Dry air or a foam swab are the recommended supplies to use when cleaning a sensor. Either blow the dust / debris from the sensor using dry clean compressed air or wipe the sensor with a dry clean swab.

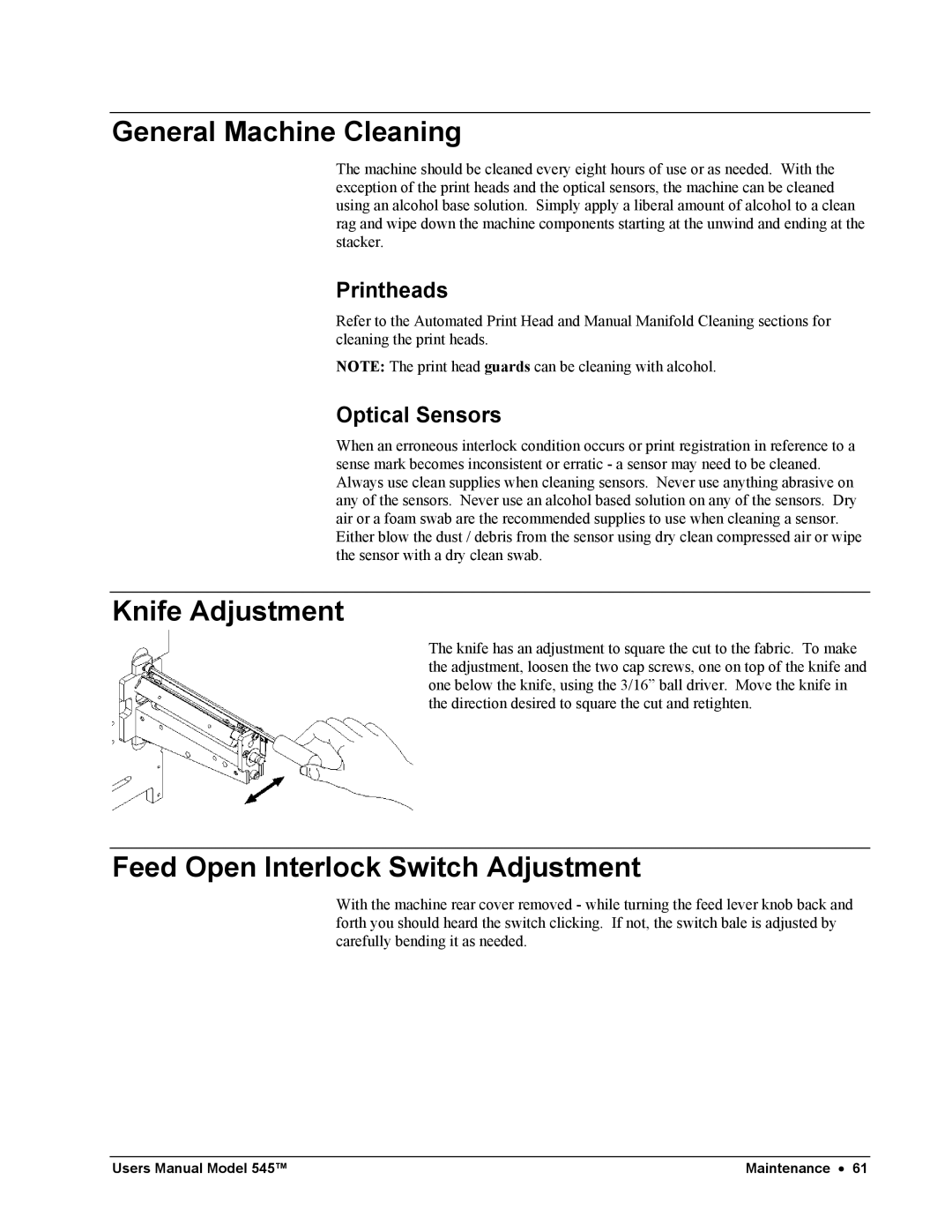

Knife Adjustment

The knife has an adjustment to square the cut to the fabric. To make the adjustment, loosen the two cap screws, one on top of the knife and one below the knife, using the 3/16” ball driver. Move the knife in the direction desired to square the cut and retighten.

Feed Open Interlock Switch Adjustment

With the machine rear cover removed - while turning the feed lever knob back and forth you should heard the switch clicking. If not, the switch bale is adjusted by carefully bending it as needed.

Users Manual Model 545™ | Maintenance • 61 |