3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

3.2 CUTTER MODULE

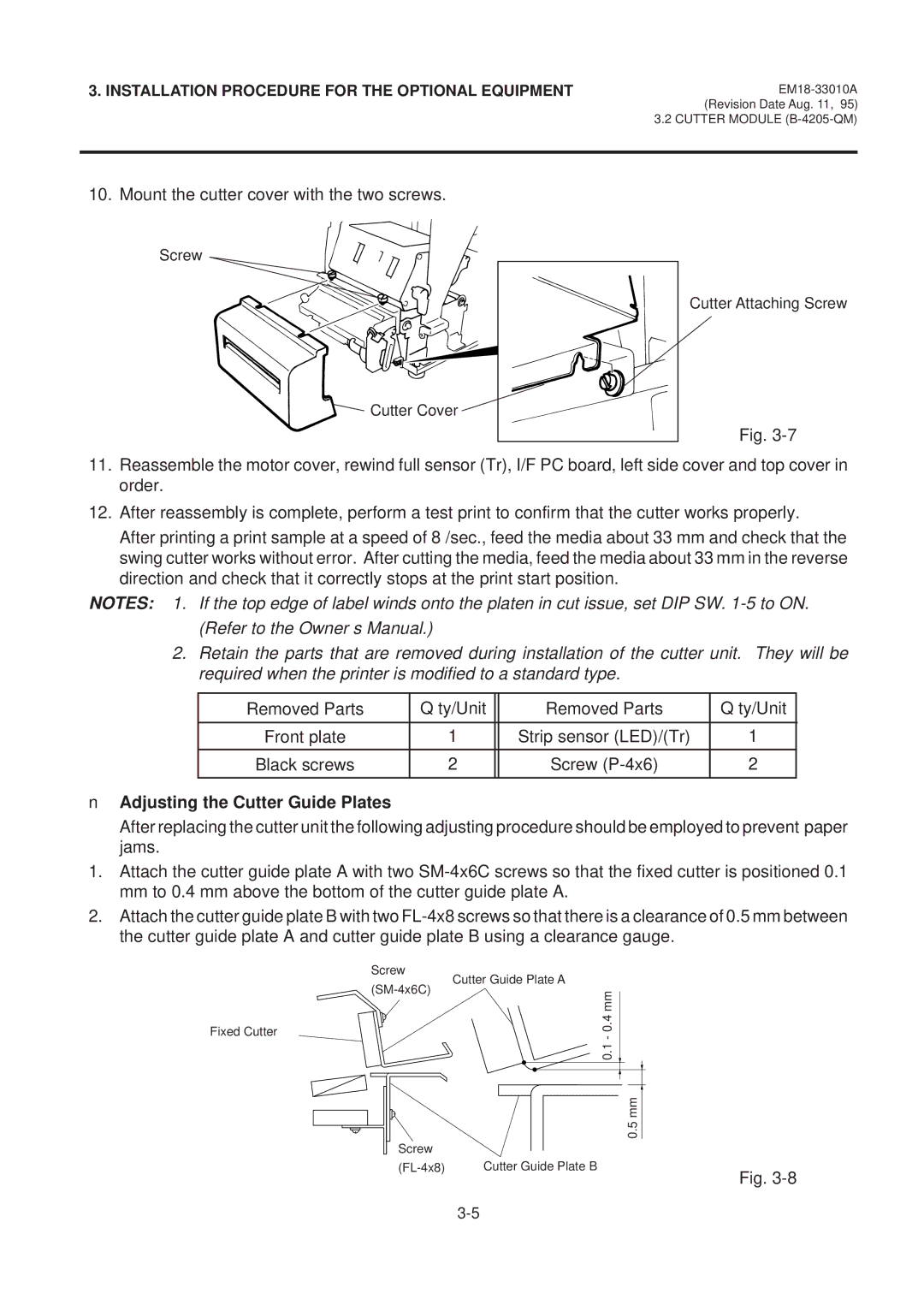

10. Mount the cutter cover with the two screws.

Screw

Cutter Cover

Cutter Attaching Screw

Fig.

11.Reassemble the motor cover, rewind full sensor (Tr), I/F PC board, left side cover and top cover in order.

12.After reassembly is complete, perform a test print to confirm that the cutter works properly.

After printing a print sample at a speed of 8”/sec., feed the media about 33 mm and check that the swing cutter works without error. After cutting the media, feed the media about 33 mm in the reverse direction and check that it correctly stops at the print start position.

NOTES: 1. If the top edge of label winds onto the platen in cut issue, set DIP SW.

(Refer to the Owner’s Manual.)

2. Retain the parts that are removed during installation of the cutter unit. They will be required when the printer is modified to a standard type.

Removed Parts | Q’ty/Unit |

| Removed Parts | Q’ty/Unit |

|

|

|

|

|

Front plate | 1 |

| Strip sensor (LED)/(Tr) | 1 |

|

|

|

|

|

Black screws | 2 |

| Screw | 2 |

|

|

|

|

|

■ Adjusting the Cutter Guide Plates

After replacing the cutter unit the following adjusting procedure should be employed to prevent paper jams.

1.Attach the cutter guide plate A with two

2.Attach the cutter guide plate B with two

Fixed Cutter

Screw

Cutter Guide Plate A

0.5 mm |

Screw

Fig.