Service of Machines

Main Service Parts for Safety

Disposition of Consumable Parts/Packing Materials

Vorsicht

Entsorgung des gebrauchten RAM-ICs inklusive

Der Lithium-Batterie nach Angaben des Herstellers

Adjustment Items Preventive Maintenance PM

Contents

Troubleshooting Based on Error Code

Firmware Updating

Appendix

Error Code List

Restart time out error

Scanner related service call

Original jam in the ADF

Original not reaching the aligning sensor

Original not reaching the exit sensor

C3F

ADF related service call

Error of aligning sensor automatic adjustment

Eeprom initializing error

Error of paper exit sensor automatic adjustment

Automatic adjustment error of bin inside paper sensor

Transport motor rotation abnormal

Bin shift motor rotation abnormal

Guide bar swing motor rotation abnormal

F11

99 08 26 17 57 236210000000 Error code

Unused

Self Diagnostic Mode

Transition diagram of self-diagnostic mode conditions

Input check Test mode

ADU side switch

A3/LD

Full COLORkey OFF, Auto COLORkey OFF, Energy SAVERkey on

Full COLORkey OFF, Auto COLORkey ON, Energy SAVERkey OFF

Full COLORkey OFF, Auto COLORkey ON, Energy SAVERkey on

Operation procedure

Full COLORkey ON, Auto COLORkey OFF, Energy SAVERkey OFF

Output check Test mode

ON/OFF

Carriage fan motor rotation when standby low speed ON/OFF

Carriage fan motor rotation when running high speed ON/OFF

Document motor indicator 1 reciprocating

SCM fan motor rotation speed Low/High

Operation procedure Group

Test print mode

Pixel modulation pattern for creating γ table

Pixel modulation pattern 1 for selecting pulse width

Pixel modulation pattern 2 for selecting pulse width

Adjustment mode

Group

OHP mode

318

Full color

~255

Fine adjustment of fuser motor rotation speed

Fine adjustment of drum motor rotation speed

Fine adjustment of feed motor rotation speed

390

Thick paper 2 mode

Thick paper 3 mode

Color registration sensor error Or 16 or above Normal

Right margin

Write start position adjust 2nd cassette

Default 9 68 msec

Modulation mode switching, type a

Modulation mode switching, type B

Density adjustment density curve selection

Color mode black text γ curve set selection

Monochrome mode black text γ curve set

Monitor patch output ON/OFF switching

Fine adjustment Text

Center setting Printed image

Darker setting Printed image

Manual density Full color Text/Photo

Lighter setting Printed image

Sity fine adjust Text

Made at the light side become

Lighter

Total hue adjustment

For ID Full color non-text area Y

For ID Full color non-text area M

For ID Full color non-text area C

Total luminance adjustment

Total saturation adjustment

Tend to be judged as color Auto-color mode

Adjustment

AI mode setting Time-out setting

Macro recognition Pre-process text threshold Adjustment

Macro recognition Pre-process shading Threshold adjustment

Adjustment Map

Micro recognition Text emphasis adjustment

When the value increases, the im

Default is equivalent to

Micro recognition Logo text inside threshold

Fixed black ratio adjustment, type a

Fixed black ratio adjustment, type B

Fixed black ratio adjustment, type C

Fixed black ratio adjustment, type D

Color mode, black text γ adjustment

Monochrome mode, black text γ adjustment

~255 Mode become denser

Color balance

Color balance Text/Photo Low density

High density

Text Low density

Photo Low density

Output value indica When the light source

Procedure Group

Power Cancel Clear

Energy Saver Start

Setting mode

Following items can be set or changed in this mode

Timer for Print job start up time Set number Seconds

Is disabled

All clearing by key copy counter Disabled 1Enabled Removal

Original

269

Radf

Image quality control auto-start

When 1 is set, a paper source becomes

Disabled Enabled

Start count setting of developer

Paper source priority A4/LT

Secondary scanning 100% 1 101% Reproduction ratio adjustment

Radf priority mode Continuous feeding by Start key

Function clearing immediately Invalid 1 Valid After copying

Image repeat gap

Invalid Other than

Power shutoff Low power

All clearing of image processing Adjustment values

All clearing of pulse width Selection adjustment results

All clearing of γ correction Table adjustment results

Refer to Counter function and maintenance chacke list

Full-color print counter Copier

Display of counter value Code 08-802 is Reflected

Black print counter Copier

Radf original counter

Drum C life counter display/0

Refer to Counter function and maintenance check list

906

Does not start 1 Starts

Available during MFP

Invalid Valid

System mode display

Procedure for registering ID codes

Registering/changing ID codes

Correcting ID code

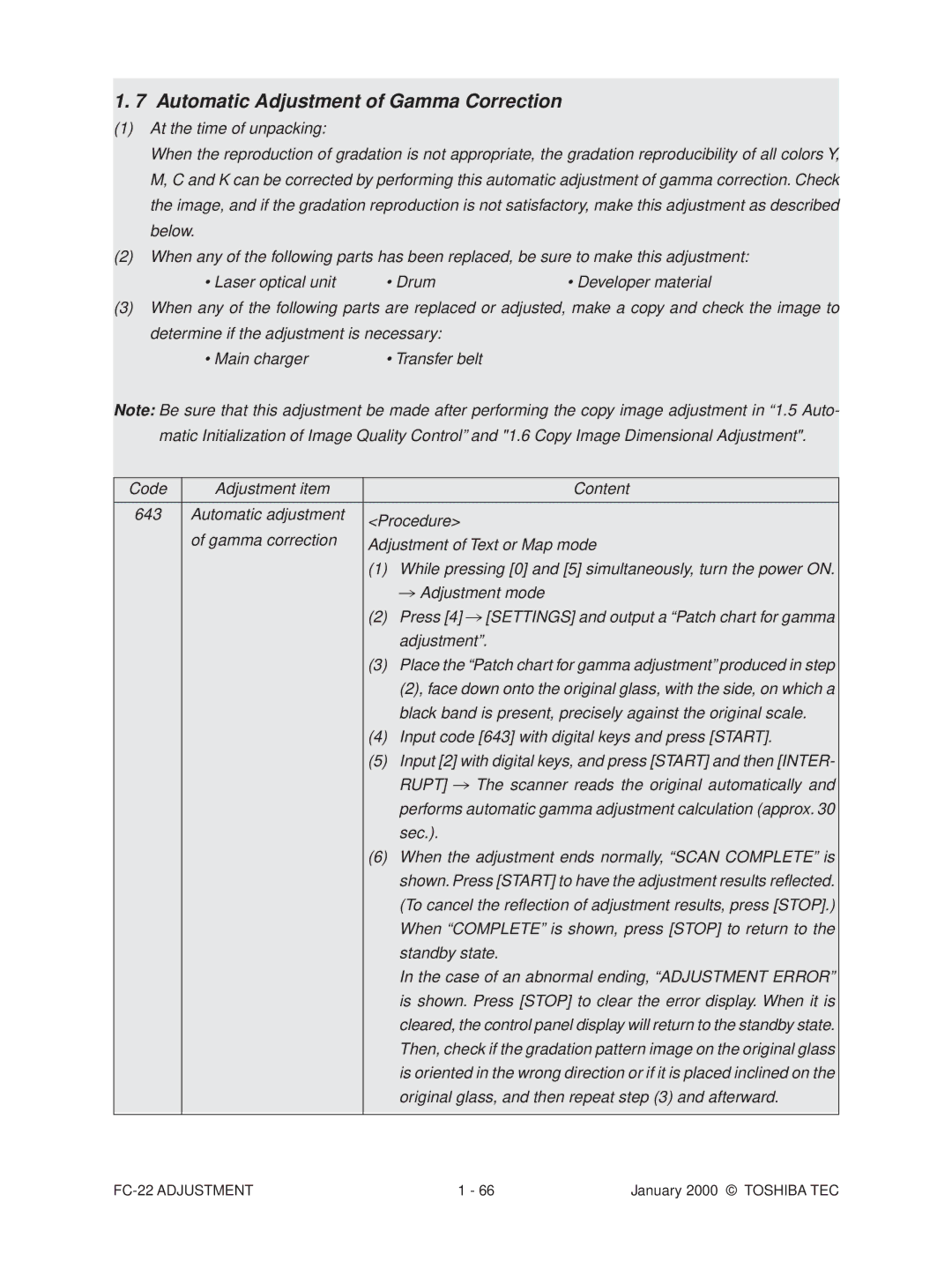

Adjustment Order Copy Image Related Adjustment

Automatic Adjustment of the Auto-Toner Circuit

100% AA3

Wait

Remove the developer cartridges Install the toner cartridges

Replace disabled parts

03-113 ON, 03-163 OFF

Check if the developer cartridge gears rotate properly

Replace EPU

Automatic Initialization of Image Quality Control

Copy Image Dimensional Adjustment

XXX

Which occurs when the paper scrapes on

Long size 439 441 443 445 Short size 440 442 444 446

447 448

449

Feed motor speed adjustment

Printer related adjustment

FC-22 Adjustment

Grid pattern

Scanner related adjustment

Step

Application Method of the Adhesive for Screw Locking

Application area Carriage frame Mirror

Image skewing adjustment

FC-22 Adjustment

LCF

FC-22 Adjustment

Chart TCC-1

Adjustment order

Toshiba Color Chart

Place the Patch chart for gamma adjustment produced in step

Shown. Press Start to have the adjustment results reflected

Transfer belt

Input 2 with digital keys, and press Start and then Inter

FC-22 Adjustment

Remarks

550 551

Manual-density

Full Dark step value Dark side becomes 570 571

Copy mode Item to be

Photo Map Remarks Adjusted

Acceptable values 0 to

255

Copy mode Item to be adjusted Remarks

Color 698 699

702 Offset value for

Background Background becomes

Judgment Threshold for ACS

AI Mode Setting

Code Color mode Copy mode Content

AI photo area Have to make adjustment by compromising

AI text area Image becomes

AI photo area Smaller the value, the less moire tends to

High-Voltage Transformer Settings

Settings after replacing main high-voltage transformers

Overview

Settings after replacing transfer transformer

Adjusting Doctor-to-Sleeve Gap

Adjusting the Scanner Section

Adjusting the Carriages

Installing the carriage drive wires to the wire pulleys

Relationship between wound turns and wire holder jigs

Lens Unit

Loosen 2 screws for fixing the lens unit

Marking Adjustment Direction

FC-22 Adjustment

Adjusting the Cassette for Sidewise Deviation

Key Copy Counter MU-8, MU-10

08 setting mode, enter 3 under code

Preventive Maintenance PM

Types of Preventive Maintenance

Preventive Maintenance Checklist

Symbols used in the checklist For FC-22

Symbols used in the checklist For FC-15

General Maintenance Checklist FC-22

Original glass Z60or a Platen cover Mirror

TBU

Color Maintenance Checklist FC-22

General Maintenance Checklist FC-15

Image quality sensor’s area Z40

Color Maintenance Checklist FC-15

53 52 51 54 56 57

Front sectional view

Processing unit EPU

Front-side drive system

Such as screws on the table

Developer material

FC-22 Preventive Maintenance

PM Kit

SR-FC22H

20K kit

Page

List of Adjustment Tools

Test chart No. TCC-1

Scanner carriage jig

Precautions for Storing Toshiba Supplies

Checking and Cleaning of the Photoconductive Drum

FC-22 Supplies

Checking and Cleaning of the Fuser Rollers

Checking and Replacing the Transfer Belt

Checking and Replacing the Transfer Roller

Troubleshooting Based on Error Code

Reconnect the connector. Replace the harness

Is the fuser motor rotating?

Disconnected?

E03 Paper remaining inside the copier at power on

Paper feeding jam E11 Paper misfeed from the ADU

E12 Paper misfeed from the bypass

Replace the cassette-feed jam sensor Replace the LGC board

E19 Paper misfeed from the LCF

Reconnect the connector. Replace the harness

Cover open jam E41 Front cover opened during copying

Close the front cover or the paper exit unit

E42 Side door opened during copying

Is the side door open?

E45 LCF jam access cover opened during copying

Is the LCF jam access cover open?

Close the LCF jam access cover

E43 ADU unit pulled out during copying

E46 Bypass unit opened during copying

Is the bypass unit open?

Close the bypass unit

E52 Paper not reaching the ADU path sensor

Have too many originals been placed?

Original does not reach the aligning roller

Original stops, skewed on the original glass

Paper jam in the sorter EA1 Paper transport delay jam

Paper transport stop jam

Paper remaining on the sorter transport path at power on

EA4 Sorter front door opened during copying

Is the stapler unit cover securely closed?

EA5

Staple jam

EC3 OHP sheet used in non-OHP mode

Is the ADU motor rotating properly?

C09 Black developer motor rotation abnormal

Is the black developer motor rotating properly?

C0A Color developer motor rotation abnormal

Is the color developer motor rotating properly?

Drum motor K rotation abnormal

Drum motor C rotation abnormal

Drum motor M rotation abnormal

Drum motor Y rotation abnormal

Put the belt on properly

C12 ADU paper end guide function abnormal

Replace the gear

Do the switches and sensors in the LCF unit function?

C18 LCF tray function abnormal

C28

C29 Exposure lamp disconnection detected

Replace the harness. Reconnect the connectors

Is used toner jammed? Is any abnormal mechanical load found?

C33 Developer removal shutter function abnormal

C35 Transfer belt unit contact/release function abnormal

C37 Transfer belt motor rotation abnormal

C38 C39

Replace the auto toner sensor Replace the LGC board

Reinstall the main charger

Reconnect the wire cleaner home position switch

Reconnect the wire cleaner limit switch

Securely

C42 Thermistor abnormal after the copier becomes ready

FC-22 Troubleshooting

C48 Heater abnormal high temperature

Error C7

C41

FC-22 Troubleshooting

FC-22 Troubleshooting

FC-22 Troubleshooting

C73 Eeprom initializing error

C74 Error of exit sensor automatic adjustment

Other service calls C94 Main-CPU abnormal

Observe the condition for a while

C9A Main memory abnormal

C9E IMC board connection abnormal

Replace the laser optical unit

CA2 H-SYNC abnormal

Is the polygonal motor rotating?

Sorter related service call

Transport motor rotation abnormal

CC3

Bin-shift motor rotation abnormal

Guide bar swing motor rotation abnormal

Stapler-unit swing motor rotation abnormal

Automatic adjustment error of bin inside paper sensor

CCA

No power being supplied

Press the circuit breaker

Is the fuse blown out?

Replace the fuse

Image quality related service call

Image quality sensor abnormal OFF level

CE2

Image quality sensor no pattern level

CE4 Image quality control test pattern abnormal

CE5 Temperature/humidity sensor upper-limit abnormal

CF1 Color registration control abnormal

FC-22 Troubleshooting

FC-22 Troubleshooting

FC-22 Troubleshooting

F11 Communications error between System-CPU and Scanner-CPU

FC-22 Troubleshooting

Troubleshooting of Image

Color deviation Symptoms

Few steps at a time

Uneven pitch and blur Symptoms

FC-22 Troubleshooting

FC-22 Troubleshooting

Defect of image density, color reproduction and gray balance

Background Fogging

Moire/lack of sharpness

Lack of sharpness

Toner offset Feeding direction

Vents because they have bad effect on drum

Fuser roller pressure defect

Check/correct developer sleeve coupling engaging

Solid copy Feeding direction

White banding in feeding direction directionFeeding

Check/correct related circuits

Skew slantwise copying Feeding direction

LCF

Color banding in feeding direction Feeding direction

FC-22 Troubleshooting

White spots Feeding direaction

Cause/Defect area Step Check items Measures Developer unit

Poor image transfer Feeding direction

Uneven image density Feeding direction

Cause/Defect area

Image dislocation in feeding direction Feeding direction

Image jittering Feeding direction

Poor cleaning Feeding direction

Oil roller Life ended? Fuser roller

Uneven light distribution Feeding direction

Blotched image Feeding direction

3 9 Mode Operation

Outline

Preparation of PC

\WEBSHARE\FTPROOT

FC-22 Firmware Updating

Firmware update operation

One of the followings SJP, SEU, SUC, SX

SJP

Case of 1

Case of #1 #3

Error Message

Case of #1 #3 Following screen is displayed after finished

Further procedure is the same as normal sequence

Following screen will be displayed in 3 9 mode

Screen details

Press Start Key

Case of #1- #3

’ Press Start Key

Error Occurrence Area Power OFF

Installation Instructions for Firmware Update through PC

System configuration

Preparation of PC to use a network

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

Installation of FTP server

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

FC-22 Firmware Updating

Wire Harness Connection Diagrams

AC Wire Harness

DC Wire Harness

January 20000 Toshiba TEC