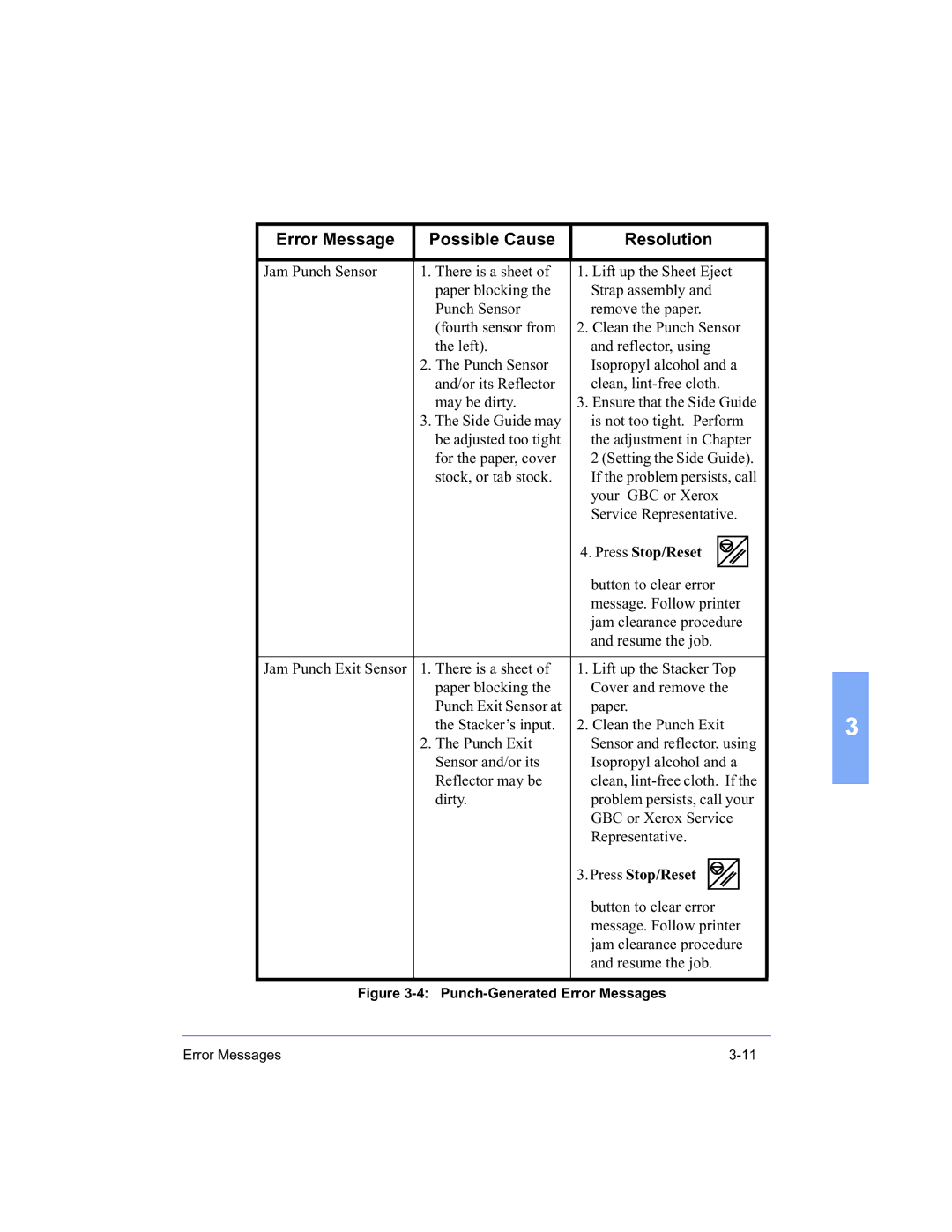

Error Message | Possible Cause | Resolution | ||||||

|

|

|

|

|

|

|

|

|

Jam Punch Sensor | 1. There is a sheet of | 1. Lift up the Sheet Eject | ||||||

| paper blocking the | Strap assembly and | ||||||

| Punch Sensor | remove the paper. | ||||||

| (fourth sensor from | 2. Clean the Punch Sensor | ||||||

| the left). | and reflector, using | ||||||

| 2. The Punch Sensor | Isopropyl alcohol and a | ||||||

| and/or its Reflector | clean, | ||||||

| may be dirty. | 3. Ensure that the Side Guide | ||||||

| 3. The Side Guide may | is not too tight. Perform | ||||||

| be adjusted too tight | the adjustment in Chapter | ||||||

| for the paper, cover | 2 (Setting the Side Guide). | ||||||

| stock, or tab stock. | If the problem persists, call | ||||||

|

| your GBC or Xerox | ||||||

|

| Service Representative. | ||||||

|

| 4. Press Stop/Reset |

|

|

|

|

| |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| button to clear error | ||||||

|

| message. Follow printer | ||||||

|

| jam clearance procedure | ||||||

|

| and resume the job. | ||||||

|

|

|

|

|

|

|

|

|

Jam Punch Exit Sensor | 1. There is a sheet of | 1. Lift up the Stacker Top | ||||||

| paper blocking the | Cover and remove the | ||||||

| Punch Exit Sensor at | paper. | ||||||

| the Stacker’s input. | 2. Clean the Punch Exit | ||||||

| 2. The Punch Exit | Sensor and reflector, using | ||||||

| Sensor and/or its | Isopropyl alcohol and a | ||||||

| Reflector may be | clean, | ||||||

| dirty. | problem persists, call your | ||||||

|

| GBC or Xerox Service | ||||||

|

| Representative. | ||||||

|

| 3. Press Stop/Reset |

|

|

| |||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

| |||

|

| button to clear error | ||||||

|

| message. Follow printer | ||||||

|

| jam clearance procedure | ||||||

|

| and resume the job. | ||||||

|

|

|

|

|

|

|

|

|

Figure 3-4: Punch-Generated Error Messages

3

Error Messages |