Cleaning the FusionPunch II

Your FusionPunch II is designed as a

When to Clean

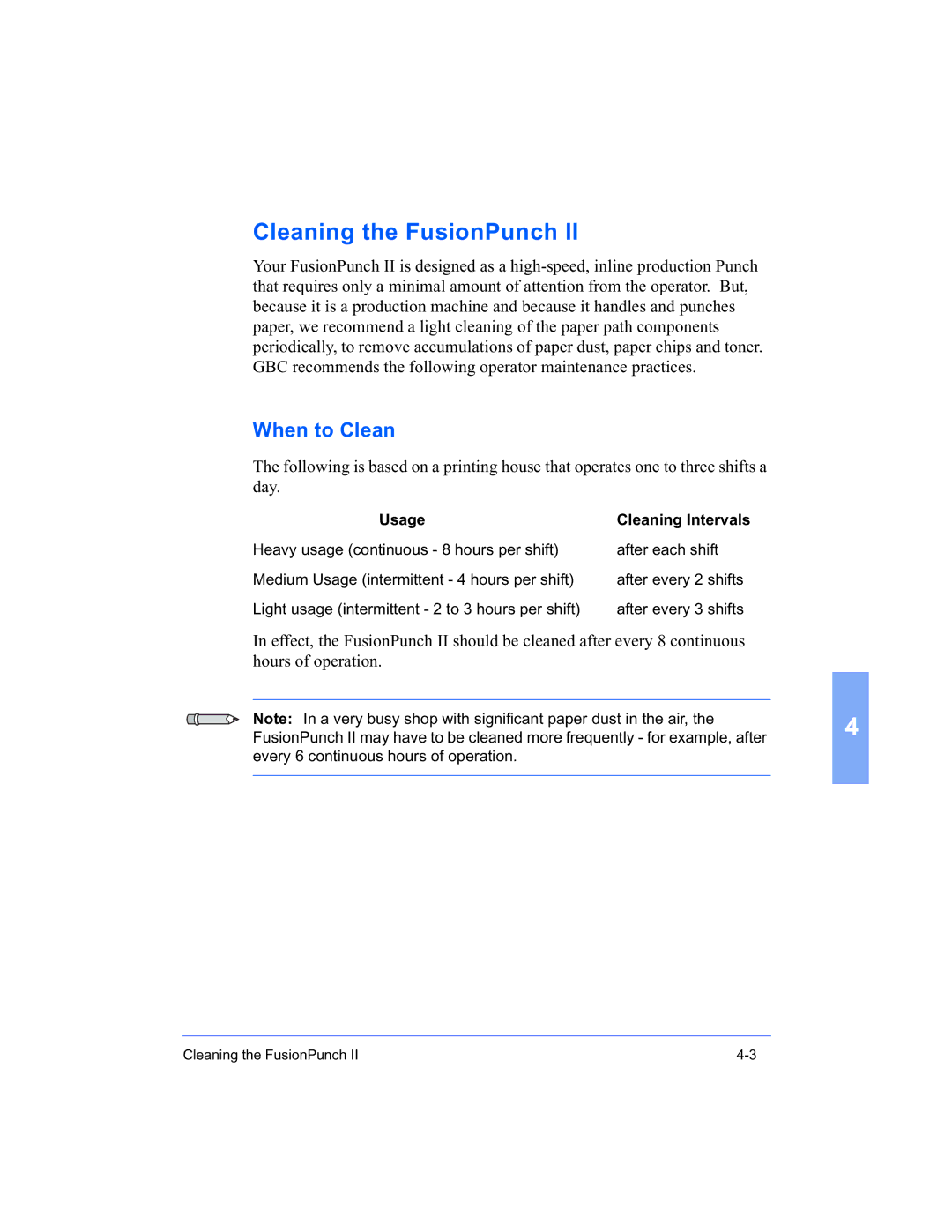

The following is based on a printing house that operates one to three shifts a day.

Usage | Cleaning Intervals |

Heavy usage (continuous - 8 hours per shift) Medium Usage (intermittent - 4 hours per shift) Light usage (intermittent - 2 to 3 hours per shift)

after each shift after every 2 shifts after every 3 shifts

In effect, the FusionPunch II should be cleaned after every 8 continuous |

| ||

hours of operation. |

| ||

|

|

| |

Note: In a very busy shop with significant paper dust in the air, the | 4 | ||

FusionPunch II may have to be cleaned more frequently - for example, after | |||

| |||

every 6 continuous hours of operation. |

| ||

|

|

| |

|

|

| |

Cleaning the FusionPunch II |