46 | Section 4 System Programming |

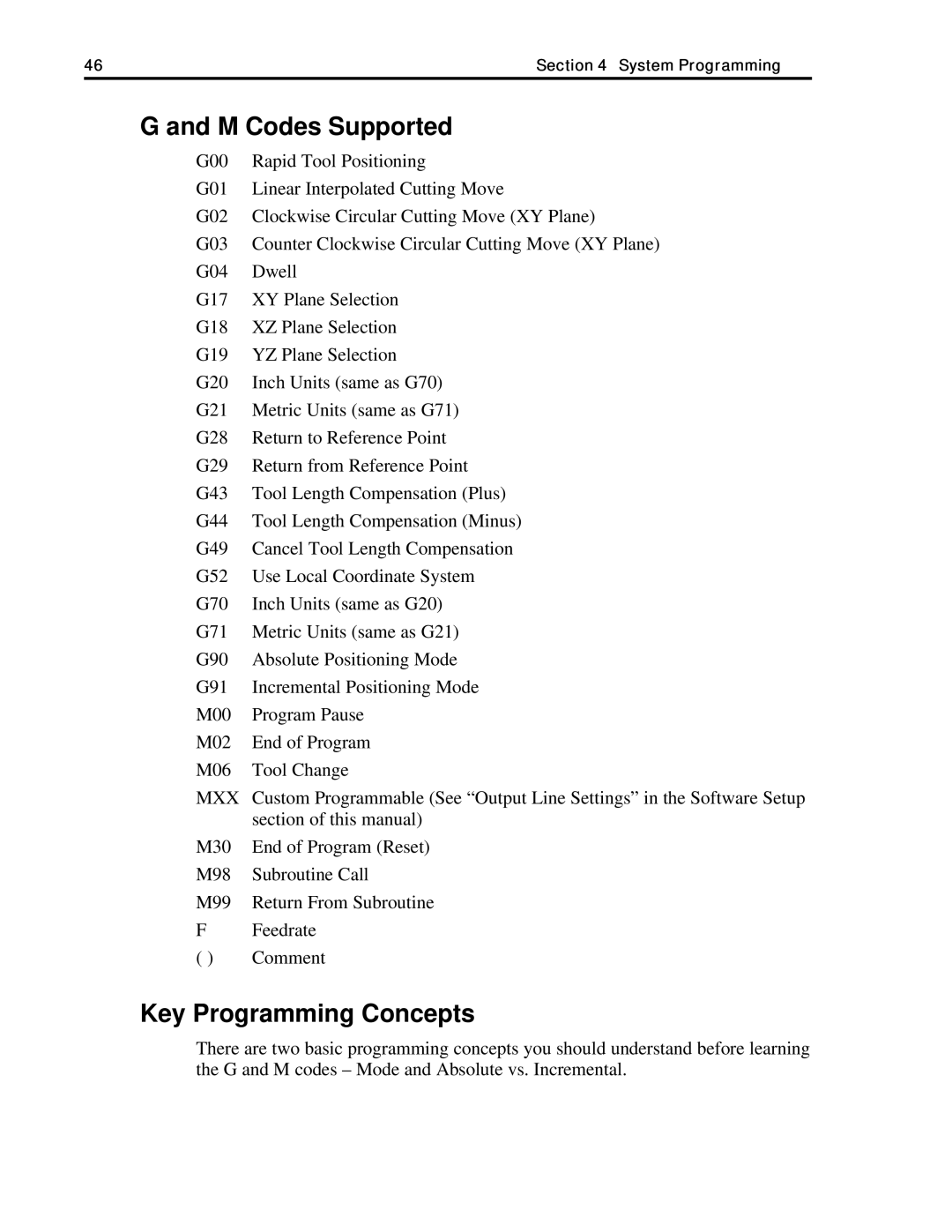

G and M Codes Supported

G00 Rapid Tool Positioning

G01 Linear Interpolated Cutting Move

G02 Clockwise Circular Cutting Move (XY Plane)

G03 Counter Clockwise Circular Cutting Move (XY Plane)

G04 Dwell

G17 XY Plane Selection

G18 XZ Plane Selection

G19 YZ Plane Selection

G20 Inch Units (same as G70)

G21 Metric Units (same as G71)

G28 Return to Reference Point

G29 Return from Reference Point

G43 Tool Length Compensation (Plus)

G44 Tool Length Compensation (Minus)

G49 Cancel Tool Length Compensation

G52 Use Local Coordinate System

G70 Inch Units (same as G20)

G71 Metric Units (same as G21)

G90 Absolute Positioning Mode

G91 Incremental Positioning Mode

M00 Program Pause

M02 End of Program

M06 Tool Change

MXX Custom Programmable (See “Output Line Settings” in the Software Setup section of this manual)

M30 End of Program (Reset)

M98 Subroutine Call

M99 Return From Subroutine

FFeedrate

( ) Comment

Key Programming Concepts

There are two basic programming concepts you should understand before learning the G and M codes – Mode and Absolute vs. Incremental.