Lin+Drive Servo Control

Table of Contents

Ii Table of Contents MN1851

Minimum system requirements

24VDC Logic Power Input

Appendix a

Appendix B

Iv Table of Contents MN1851

Limited Warranty

Section General Information

CE Compliance

Product Notice Intended use

Could result in injury or death

Could result in damage to property

General Information MN1851

Do not touch any circuit board, power device or electrical

Connection before you first ensure that power has been

Do not apply AC power before you ensure that grounds are

Voltages that are conducted to its power input terminals.

General Information MN1851

Section Product Overview

Control Outputs

Encoder Output

Section Receiving and Installation

Mechanical Installation

Receiving & Installation MN1851

Control

GND

Recommended System Grounding 1 phase for UL

Recommended System Grounding 1 phase for CE

Input Power Conditioning

System Grounding Ungrounded Distribution System

Wire Size for units without Power Supply

X1 Power Connections

Breaker

Mm2

Components not provided with Control

Baldor

Baldor Control

Earth

Breaker

Baldor Option S Option P Control Regen Resistor

Baldor Option P Control

� Important

LPxAxxxx-xxx3 only

Holes in the top and bottom

Enclosure are for cable clamps. Be sure

To use an M4 bolt 12mm in length

Longer bolts may short circuit

11 Motor Connections for UL

12 Motor Connections for CE

13 Optional M-Contactor Connections

Control Input Wiring

X3 Control Inputs & Digital I/O Connections

Single Ended Connection Differential Connection

X3 Digital Inputs Opto Isolated Inputs uses Cref

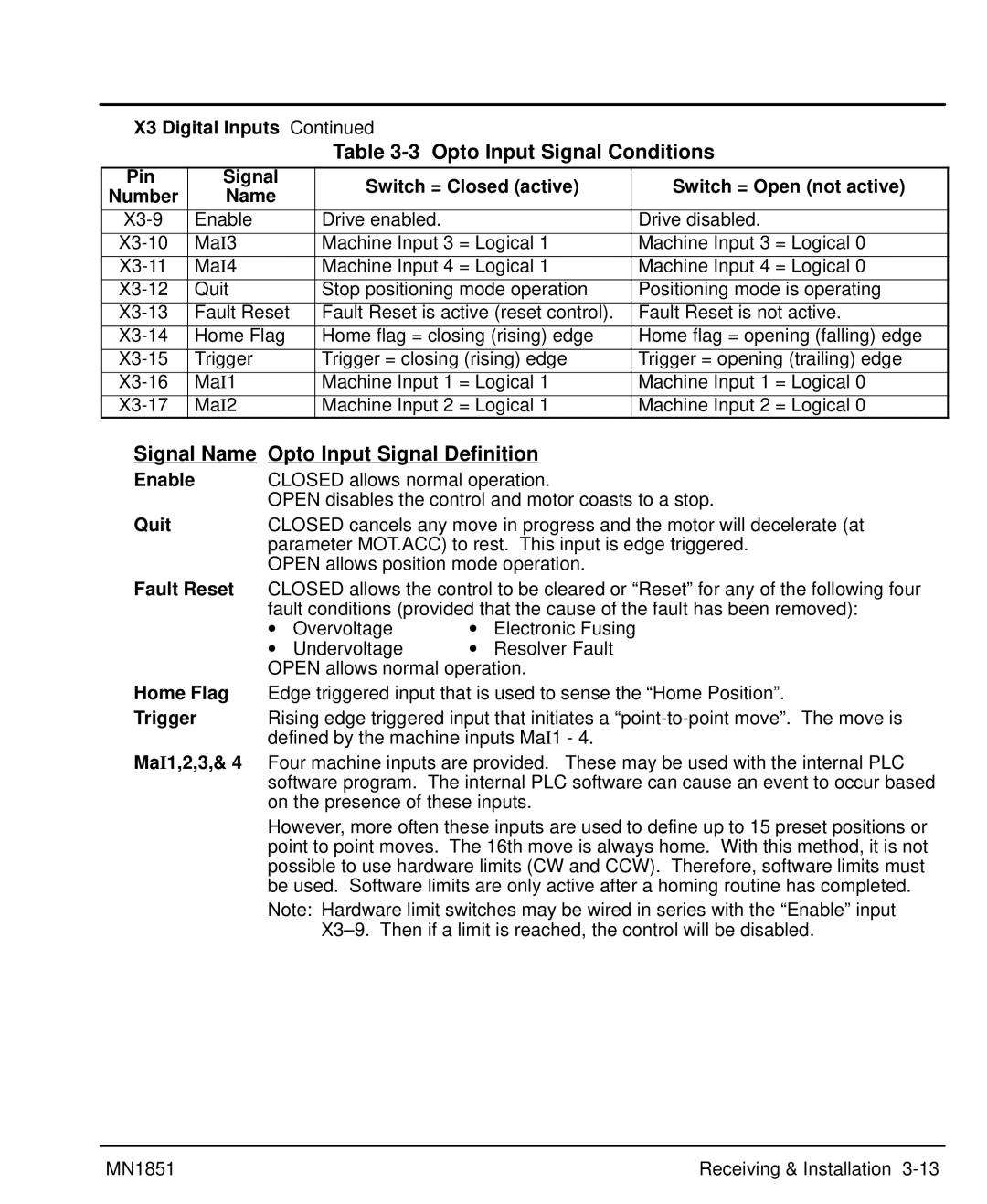

Opto Input Signal Conditions

Signal Name Opto Input Signal Definition

Process Duration

Time Required Duration

Opto Output Signal Conditions

Fault Relay

X3 Digital Outputs

MaO1

X6 RS232 / 485 Connections

Null Modem Cable Connections

Control TXD

Computer

What is a termination resistor?

Where are these resistors placed?

RS485

How many resistors should my system have?

= Twisted Pair

TX+ Dgnd GND

TX+ RX+ Dgnd

TX+ RX+ Dgnd GND

Buffered Encoder Output at X7 Connector

X7 Pin Signal Name

X7 Encoder Output

Reserved

X9 Encoder and Hall Feedback LPxAxxxx-Exxx

Section Switch Setting and Start-Up

Switch AS1 Settings

Control Address Setting

Address Setting, AS1-1 to AS1-4 for Multi-Drop Applications

Setting of switches AS1-5 to AS1-8

Switch Function

Offset Tuning

AS1-5 to AS1-8 Description

Start-Up Procedure

Power Off Checks

Power On Checks

Procedure

Switch Setting & Start-Up MN1851

Installing Software on your PC

Host Communications Setup

Section Operation

Windows

Windows NT

Using The Setup Wizard

Flowchart of the Setup Wizard

Operation MN1851

Page

There are 7 parts to the setup procedure Motor

Motor parameters. Click Download when finished

Encoder Feedback

Encoder Feedback Motor pitch mm 60.96

Encoder Feedback

Lmcf All Micron Counts / meter Counts / mm

Operating Mode Selection Screen

Operating Mode

Current Parameter

MN1851 Operation

Software Triggered

MAI4 MAI3 MAI2 MAI1

Procedure to define home position

Home

Index channel, Capture and Actual Position

Set this value. Click Download when finished

Drift

Setup

Main Menu Choice Descriptions

File

Edit

Tuning

Watch

Functions

Motion

PLC Program Menu

Help

Velocity Parameters RPM m/s

Linear Motor

Meters/second

Section Troubleshooting

1Operating Mode Indications

MN1851 Troubleshooting

Overview

Long as the error is less than ± 215 ±

Section Specifications & Product Data

Identification

Specifications

To 3300 feet 1000 meters. Derate the continuous

+0 to 40. Above 40 C, derate the continuous and peak

Output current by 2.5% per C above 40 C. Maximum

Peak output current by 1.1% for each 330 feet

Description Unit

24VDC Logic Power Input Option LPxAxxxx-xxx3 only

24VDC Logic Power Input Option LP4Axxxx-xxx3 only

Specifications & Product Data MN1851

Velocity Control

Encoder Input Feedback

Regeneration

Dimensions

Size A, B and C

Clearance Requirements all sizes 0.06″ 15mm top and bottom

Wiring of Shielded Screened Cables

Section CE Guidelines

CE Declaration of Conformity

EMC Conformity and CE Marking

EMC Wiring Technique

CE Guidelines MN1851

Grounding Earth

EMC Installation Instructions

Cable Screens Grounding

Input Signal Cable Grounding

Simulated Encoder Output Cable Grounding

Encoder Input Cable Grounding

To Controller

Section Accessories and Options

Connectors

Mating Connector by connector number for spare parts

Cables

AC Filter Dimensions

Accessories & Options MN1851

Depth = F

Fo r

Regeneration Resistor

Package

Accessories & Options MN1851

Appendix a Manual Tuning

Tools are available to make tuning easier, such as

General Tuning Rules

Manual Tuning

There are 7 parts to the setup procedure

Parameters. Click Download when finished

Manual Tuning MN1851

Motor

15240 000,000 10,000,000

Figure A-13 Current Parameter Screen

Figure A-14 Velocity Parameter Screen Drift

Figure A-15 Drift Parameter Screen

Figure A-16 Select Manual Tuning

Figure A-17 Inertia and Load Response Examples

Tracking factor

Figure A-18 PI Compensation Menu

Page

Plotting of Move

Control Window

Graphic Screen

Jog Block

Appendix B Command Set

Lin Ascii Command Set General

Syntax General structure of the Ascii command

MN1851 Command Set B-1

Pulses/rev Resolution

Parameters and Units

Encoder

Start-up with Terminal Communication and Command Examples

Execution Error invalid command

Input Buffer Overflow command line exceeded 80 char

Control Design Failure invalid control design

General Settings System Constants

Command Set MN1851

Basic System Parameters Motor Parameters MTR. prefixed

Drive Parameters typical DRV. prefixed

Software Limit Switches Parameters

Variables None Software Limit Switches Methods

MN1851 Command Set B-5

Command Description Units Range Default E2 / Par. set

PLC Parameters

Variables None PLC Methods

PLC.LINE

Relay

MN1851 Command Set B-7

OCI Interface Parameters

Digital Interface Parameters

Analog Interface Parameters

Queries / modifications of Fault Listing Variables

X1 Possible Faults X1 Fault Display Description

System Variables General Variables

Communication Settings Parameter

MN1851 Command Set B-9

Methods

Variable

Queries of System Variables, Status, Faults Single Values

Data Record REC. prefixed Parameters

Data Record REC. prefixed Variable

Operation Mode Control Normal Modes Parameters

Memory related methods Queries / modifications RAM related

Eeprom related

Normal Modes Variables

Sys.mod Current mode Parameters

Current mode Variables

Current mode Methods

Query for actual current command

Sys.mod 1 & Sys.mod Velocity mode Parameters

Velocity mode Variables

Velocity mode Methods

MN1851 Command Set B-13

Jog Parameters

JOG.TIME

JOG.TYPE

JOG.VEL

MN1851 Command Set B-15

Position Controller Position Controller Parameters

Variables

HW.GRFX

HW.GRSH

HW.PLC

HW.RES

Baldor Electric Company

Baldor Electric Company MN1851 10/00 C&J

Lin+Drive Servo Control MN1851