X1 +24VDC Logic Supply For

If the control was not ordered with this option, do not connect any voltage to these pins.

X3 Control Inputs & Digital I/O Connections

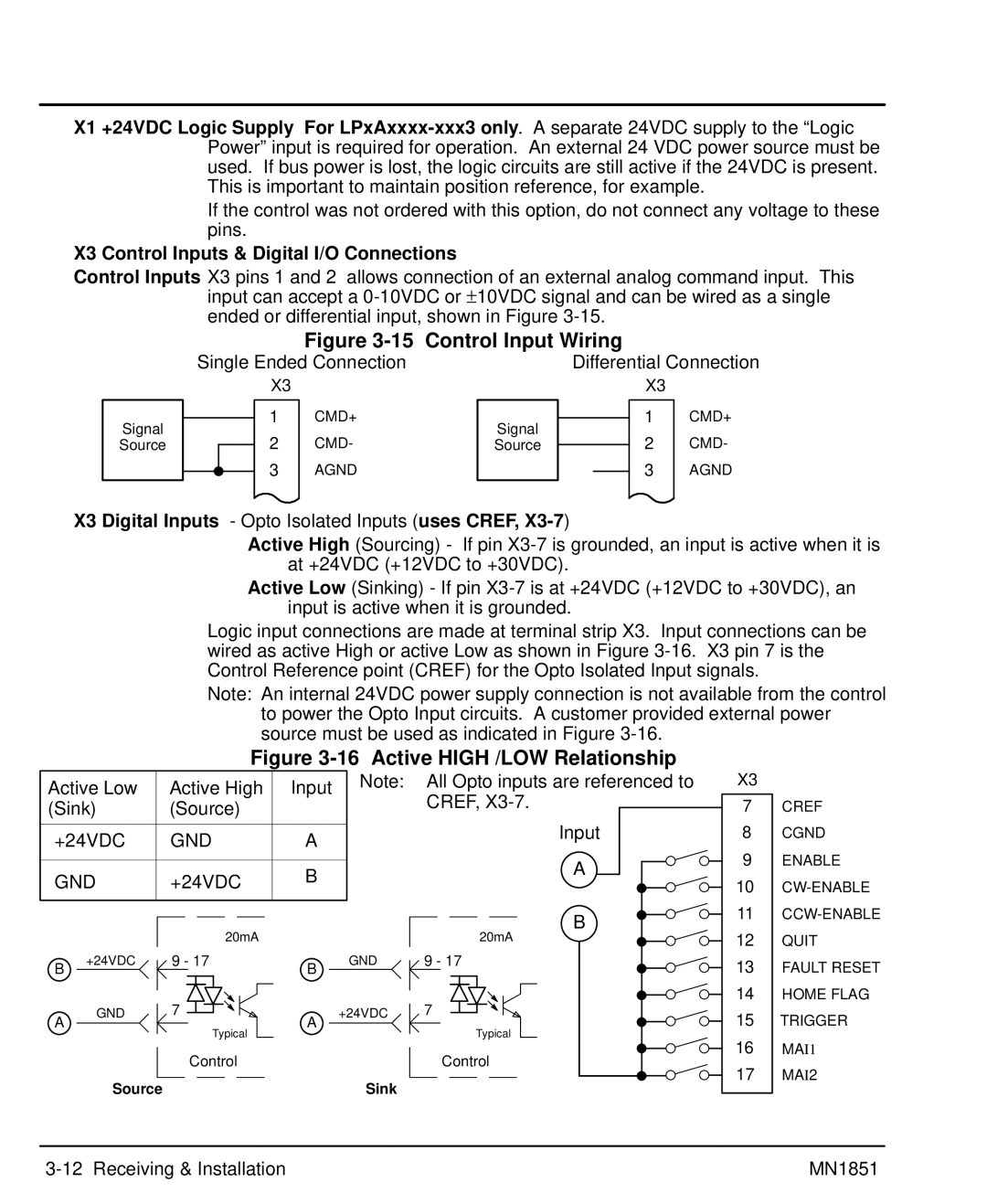

Control Inputs X3 pins 1 and 2 allows connection of an external analog command input. This input can accept a

Signal

Source

|

|

| Figure | Control Input Wiring |

| |||

Single Ended Connection |

| Differential Connection | ||||||

|

| X3 |

|

|

|

| X3 |

|

|

|

|

|

|

|

|

|

|

|

| 1 | CMD+ | Signal |

|

| 1 | CMD+ |

|

|

|

| |||||

|

| 2 | CMD- |

|

| 2 | CMD- | |

|

| Source |

|

| ||||

|

|

|

| |||||

|

| 3 | AGND |

|

|

| 3 | AGND |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

X3 Digital Inputs - Opto Isolated Inputs (uses CREF, X3-7)

Active High (Sourcing) - If pin

Active Low (Sinking) - If pin

Logic input connections are made at terminal strip X3. Input connections can be wired as active High or active Low as shown in Figure

Note: An internal 24VDC power supply connection is not available from the control

to power the Opto Input circuits. A customer provided external power source must be used as indicated in Figure

Figure 3-16 Active HIGH /LOW Relationship

Active Low | Active High | Input | Note: All Opto inputs are referenced to | ||

| CREF, | ||||

(Sink) | (Source) |

|

| ||

|

|

| |||

+24VDC | GND | A |

| Input | |

|

| ||||

GND | +24VDC | B |

| A | |

|

| ||||

|

|

| |||

|

|

|

|

| B |

|

| 20mA |

|

| 20mA |

B | +24VDC | 9 - 17 | B | GND | 9 - 17 |

|

|

|

| ||

A | GND | 7 | A | +24VDC | 7 |

| Typical |

| Typical | ||

|

|

|

| ||

|

| Control |

|

| Control |

| Source |

|

| Sink |

|

X3

7

8

9

10

11

12

13

14

15

16

17

CREF

CGND ENABLE

MAI2

| MN1851 |