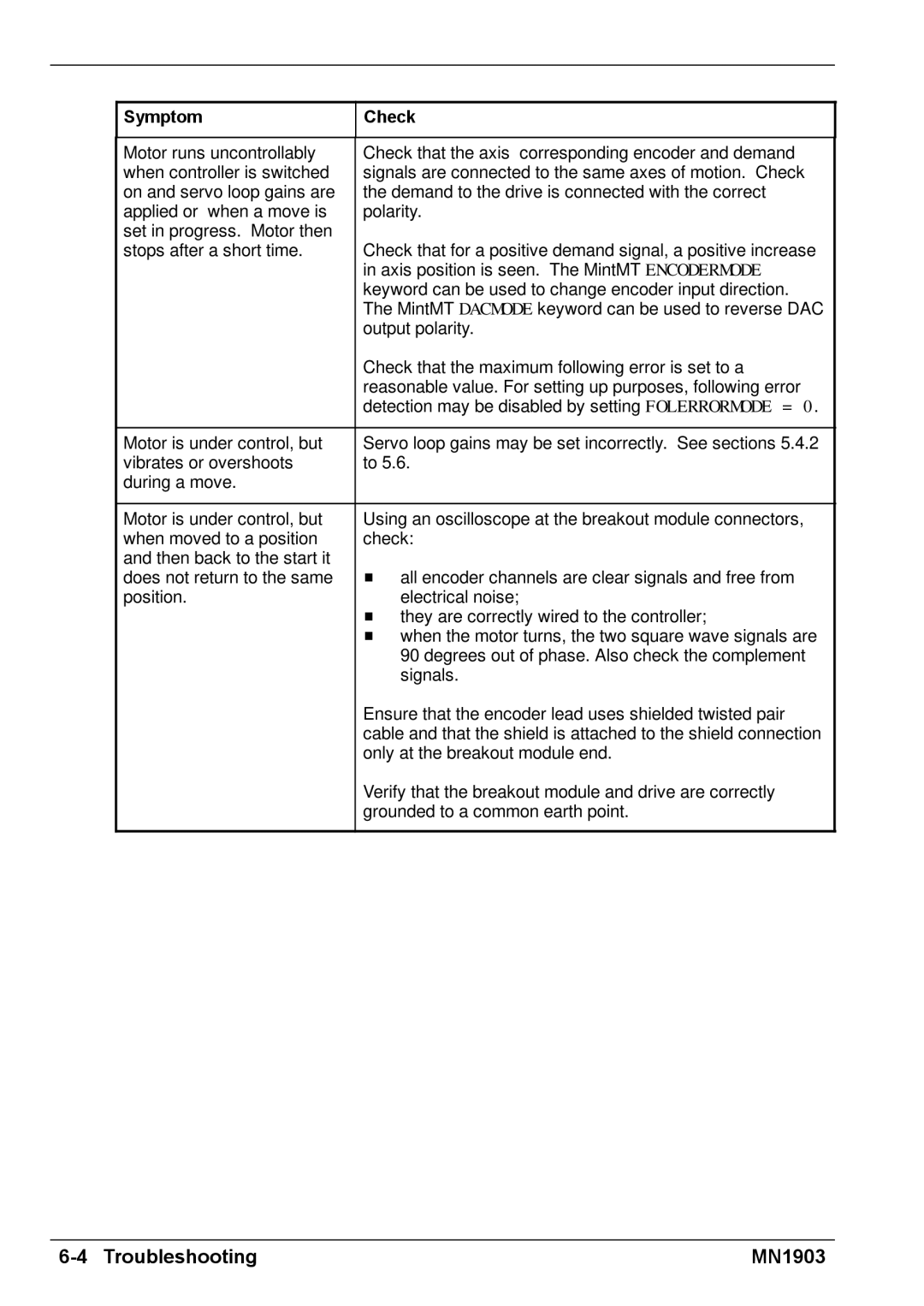

Symptom | Check |

|

|

Motor runs uncontrollably | Check that the axis’ corresponding encoder and demand |

when controller is switched | signals are connected to the same axes of motion. Check |

on and servo loop gains are | the demand to the drive is connected with the correct |

applied or when a move is | polarity. |

set in progress. Motor then |

|

stops after a short time. | Check that for a positive demand signal, a positive increase |

| in axis position is seen. The MintMT ENCODERMODE |

| keyword can be used to change encoder input direction. |

| The MintMT DACMODE keyword can be used to reverse DAC |

| output polarity. |

| Check that the maximum following error is set to a |

| reasonable value. For setting up purposes, following error |

| detection may be disabled by setting FOLERRORMODE = 0. |

|

|

Motor is under control, but | Servo loop gains may be set incorrectly. See sections 5.4.2 |

vibrates or overshoots | to 5.6. |

during a move. |

|

|

|

Motor is under control, but | Using an oscilloscope at the breakout module connectors, |

when moved to a position | check: |

and then back to the start it |

|

does not return to the same | H all encoder channels are clear signals and free from |

position. | electrical noise; |

| H they are correctly wired to the controller; |

| H when the motor turns, the two square wave signals are |

| 90 degrees out of phase. Also check the complement |

| signals. |

| Ensure that the encoder lead uses shielded twisted pair |

| cable and that the shield is attached to the shield connection |

| only at the breakout module end. |

| Verify that the breakout module and drive are correctly |

| grounded to a common earth point. |

|

|

MN1903 |