Chapter 6 Battery | 47 |

adequate ventilation and heating of the cells. Boost charging must not be applied to valve regulated cells as this will cause them to overcharge and subsequently vent.

Similarly,

Batteries are fully charged before delivery; however, storage and transportation times mean that, inevitably, some charge is lost by the time the battery is commissioned. All the cells forming the battery should be brought to the same state of charge and be recharged within 6 months of the factory charge.

It is especially important that the battery is fully charged before attempting a witness test of the autonomy time. This may require several days to complete; therefore any witness test concerning the batteries should take place only after the battery has been on uninterrupted float charge for at least one week.

Cell performance typically improves after a few weeks in service or after two or three discharge and recharge cycles.

6.4 Installation Design Considerations

![]() Note

Note

Full safety instructions concerning the use and maintenance of UPS batteries are provided in the appropriate battery manufacturers manuals. The battery safety information contained in this section relates to key considerations which must be taken into account during the installation design process and might affect the design outcome depending on localized conditions.

6.5 Battery Installation And Maintenance

6.5.1 Temperature Considerations

Battery performance depends on the ambient battery temperature. Capacity and autonomy times are quoted for a new battery operating at 20°C. Battery capacity is increased by 1% for every 1°C increase in temperature up to 25°C. If a battery is used at temperatures above 25°C, its life is reduced; consequently its capacity and UPS autonomy time will reduce more rapidly over a period of time. Operating below 20°C will reduce the battery capacity by approximately 1% to 1.5% per 1°C. For example, if a battery discharge test is attempted during the middle of winter when the ambient temperature is 5°C the battery capacity will be only 77.5% of its design value and will not satisfy its specified autonomy time.

Ambient temperature, ventilation, spacing, float voltage and ripple current all affect the battery temperature. Uneven temperature distribution through the battery string will cause the voltage distribution to be uneven which can also lead to problems — it is therefore important to maintain an even temperature across the whole battery chain.

When batteries are

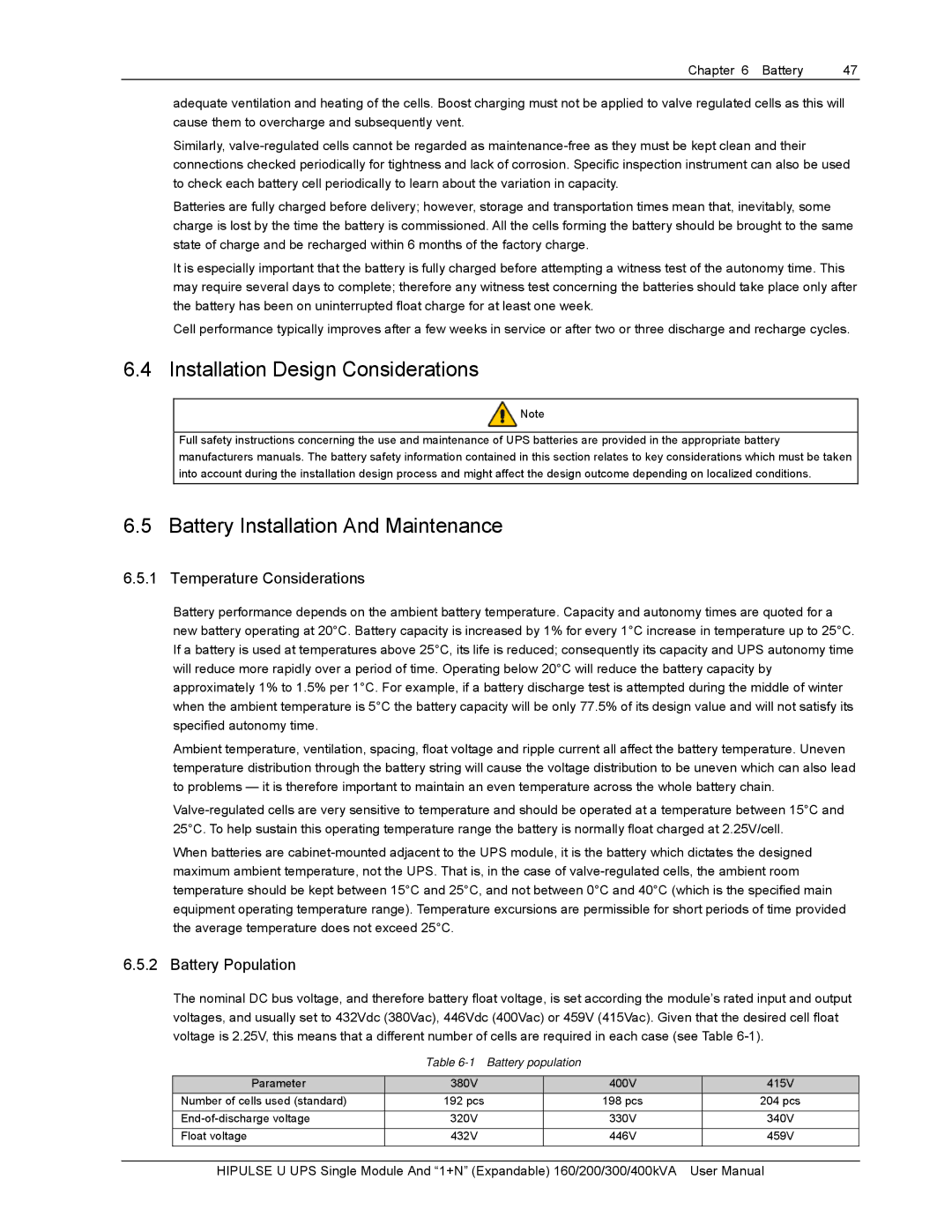

6.5.2 Battery Population

The nominal DC bus voltage, and therefore battery float voltage, is set according the module’s rated input and output voltages, and usually set to 432Vdc (380Vac), 446Vdc (400Vac) or 459V (415Vac). Given that the desired cell float voltage is 2.25V, this means that a different number of cells are required in each case (see Table

Table 6-1 Battery population

Parameter | 380V | 400V | 415V |

Number of cells used (standard) | 192 pcs | 198 pcs | 204 pcs |

320V | 330V | 340V | |

Float voltage | 432V | 446V | 459V |

HIPULSE U UPS Single Module And “1+N” (Expandable) 160/200/300/400kVA User Manual