Applications | F - 160 CE Operation and Maintenance Manual |

|

|

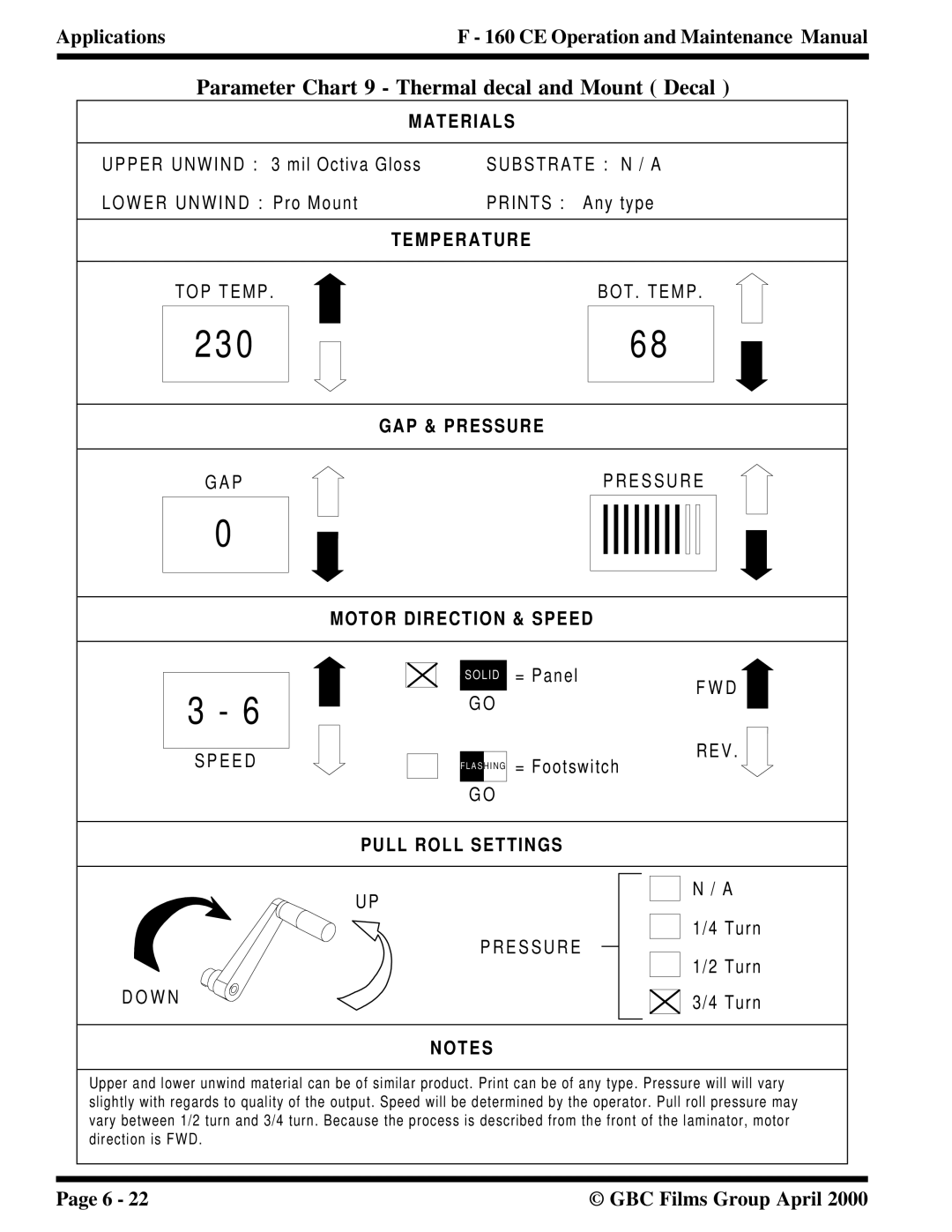

Parameter Chart 9 - Thermal decal and Mount ( Decal )

MATERIALS | |

|

|

UPPER UNWIND : 3 mil Octiva Gloss | SUBSTRATE : N / A |

LOWER UNWIND : Pro Mount | PRINTS : Any type |

T E M P E R A T U R E

TOP TEMP .

2 3 0

BOT . TEMP .

6 8

GAP & PRESSURE

G A PP R E S S U R E

0

MOTOR DIRECTION & SPEED

3 - 6

SOLID = Panel

G O

F W D

REV .

S P E E D

F L A SH I N G = Footswitch

G O

PULL ROLL SETTINGS

U P

P R E S S U R E

D O W N

N / A

1/4 Turn

1/2 Turn

3/4 Turn

NOTES

Upper and lower unwind material can be of similar product. Print can be of any type. Pressure will will vary slightly with regards to quality of the output. Speed will be determined by the operator. Pull roll pressure may vary between 1/2 turn and 3/4 turn. Because the process is described from the front of the laminator, motor direction is FWD.

Page 6 - 22 | © GBC Films Group April 2000 |