F - 160 CE Operation and Maintenance Manual | Operations |

|

|

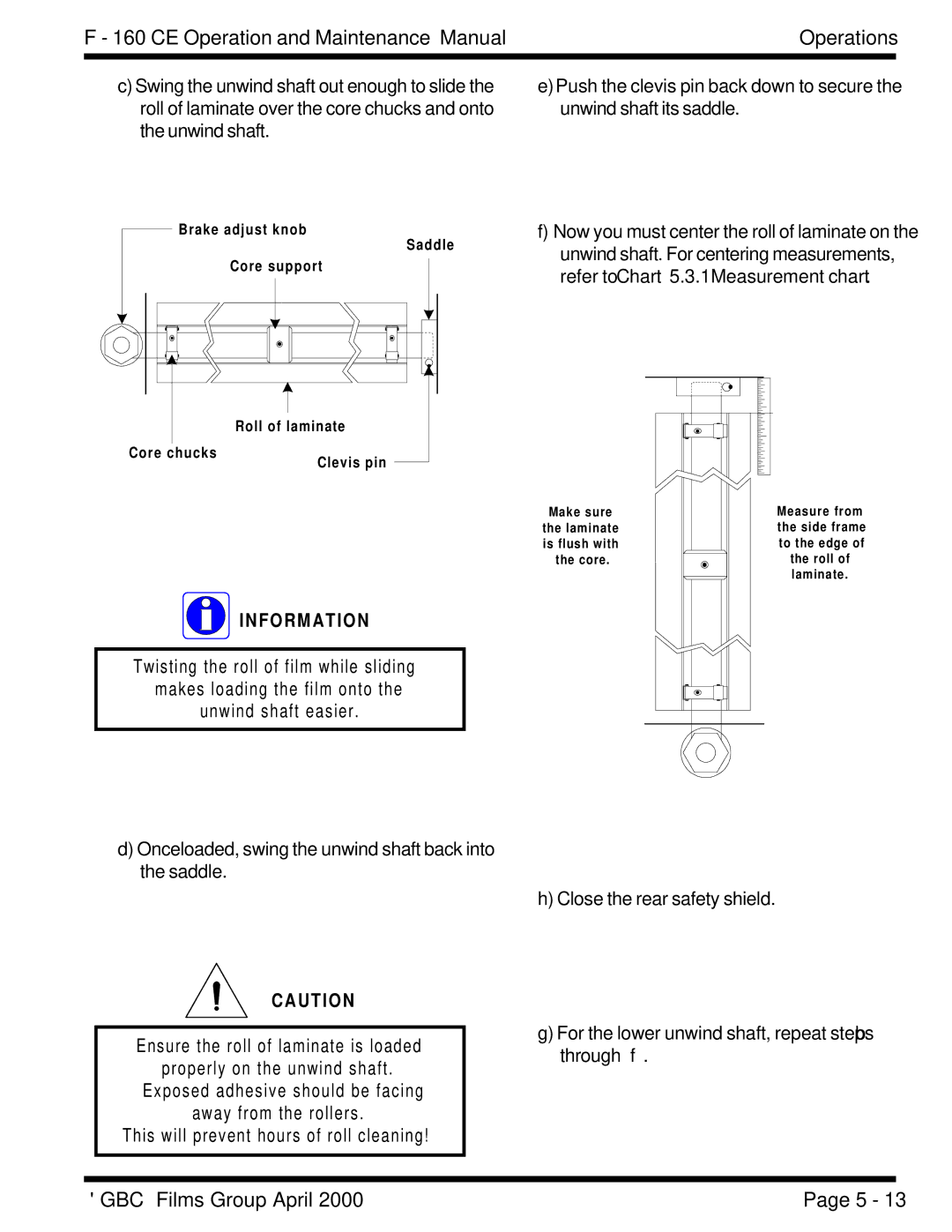

c)Swing the unwind shaft out enough to slide the roll of laminate over the core chucks and onto the unwind shaft.

Brake adjust knob

Saddle

Core support

e)Push the clevis pin back down to secure the unwind shaft its saddle.

f)Now you must center the roll of laminate on the unwind shaft. For centering measurements, refer to Chart 5.3.1 Measurement chart.

Roll of laminate

Core chucks

Clevis pin

I N F O R M A T I O N

Twisting the roll of film while sliding

makes loading the film onto the unwind shaft easier.

d)Onceloaded, swing the unwind shaft back into the saddle.

CAUTION

Ensure the roll of laminate is loaded properly on the unwind shaft.

Exposed adhesive should be facing away from the rollers.

This will prevent hours of roll cleaning!

Make sure |

|

|

|

| Measure from | |

the laminate |

|

|

|

| the side frame | |

is flush with |

|

|

|

| to the edge of | |

the core. |

|

|

|

| the roll of | |

|

|

| ||||

|

|

|

|

|

| laminate. |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

h)Close the rear safety shield.

g)For the lower unwind shaft, repeat steps “ b ” through “ f ”.

© GBC Films Group April 2000 | Page 5 - 13 |