Operations | F - 160 CE Operation and Maintenance Manual |

|

|

5.2 Emergency | 5.2.1 In an emergency |

The

GBC Films Group laminators are powerful machines that are designed to mount, laminate, and encapsulate. The forces required to accomplish these tasks can vary from negligible to very large.

The motorized main roller lift mechanism used to provide downward pressure on the upper main roller is capable of producing forces greater than 400 pounds.

W A R N I N G

This force is applied to any object presented in the opening ( called the nip ) between the two rollers.

Use care in lowering the upper laminating roller and know how to react quickly in an emergency. The main laminator roll up / down control is located on the right side of the machine within the front control panel. The GAP up / down arrows control the motion of the upper laminating roller. Before pressing GAP down arrow, ensure the nip area is clear.

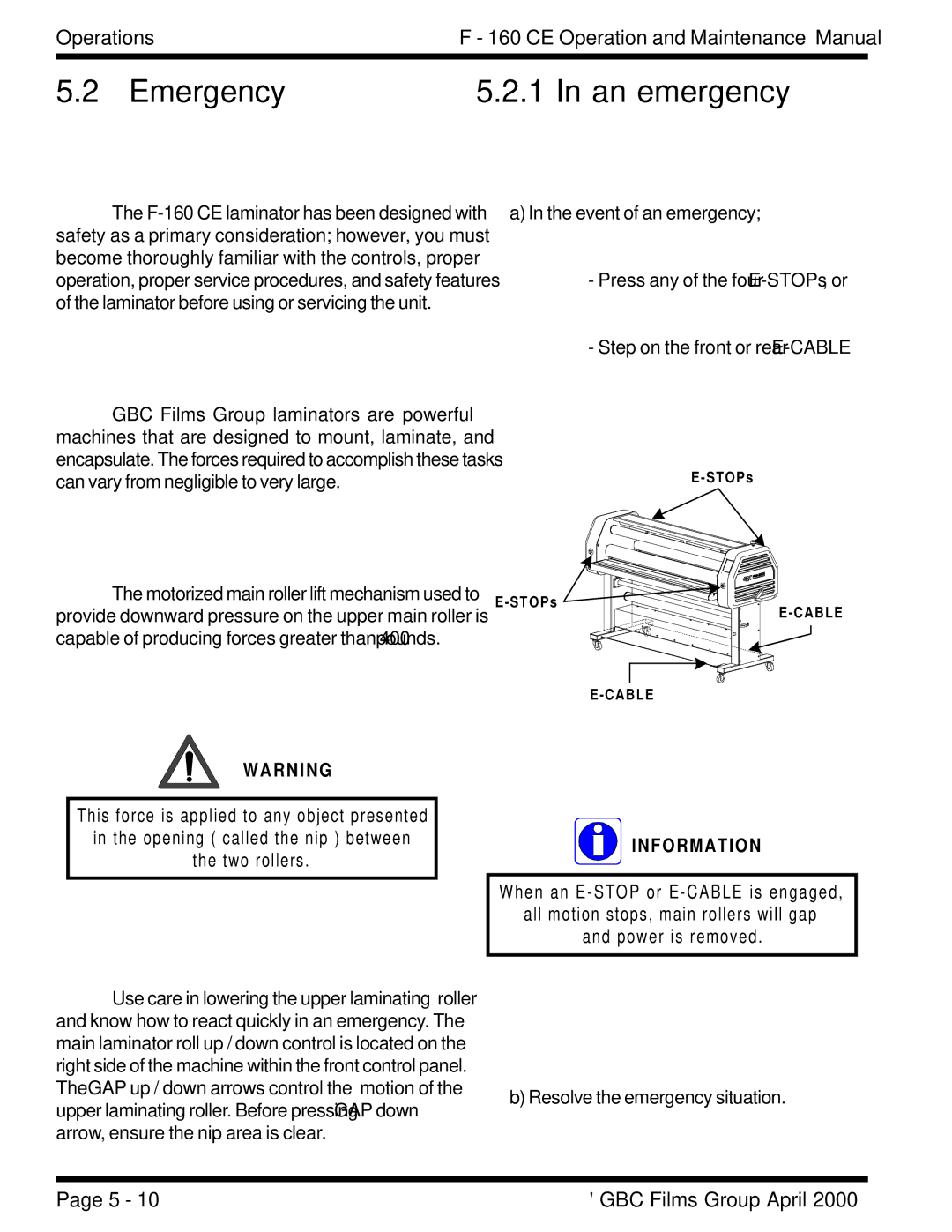

a)In the event of an emergency;

-Press any of the four

-Step on the front or rear

E - S T O P s

E - S T O P s

I N F O R M A T I O N

When an E - STOP or E - CABLE is engaged, all motion stops, main rollers will gap and power is removed .

b)Resolve the emergency situation.

Page 5 - 10 | © GBC Films Group April 2000 |