Use

Page

Use guide

Warranty

Hewlett-Packard Company Chinden Boulevard Boise, Idaho

Contents

Menu Map 104 Configuration 105 PCL or PS Font List 107

Performing Routine Maintenance

104

Glossary

Enww

Overview

Printer Basics

Printer Features and Benefits

Wide Format Printing

High Print Quality

High Performance

Expandability

Paper Handling

Best Value

Euro Character

Environmental Features

Printer Information

HP LaserJet 5100 printer

HP LaserJet 5100tn printer

HP LaserJet 5100dtn printer

Optional Tray Configurations

Power

Switch Power Connector Network, I/O, or optional

Printer Parts and Locations

Tray

Accessories and Supplies

Suggested Accessories

To ensure optimum performance

Following

Description or Use Part Number

Ordering Information

Paper

HP LaserJet Printer Family

Maintenance

Control Panel Layout

Control Panel Lights

Printer’s control panel consists of the following

Ready

Control Panel Keys

Tray x Load Type Size or Unexpected Paper Size

To change a control panel setting

Network administrator

Control Panel Menus

To print a control panel menu map

Configure the control panel display language Optional

Printer Software

Start guide for installation instructions

Software included and supported languages

Printer Drivers

Drivers Included with the Printer

Additional Drivers

Software for Windows

Access the Windows Printer Driver

Guide

Choose the Right Driver for Your Needs

Printer Driver Help

Software for Macintosh Computers

PostScript Printer Description Files PPDs

Print Dialog Extensions PDEs Mac OS X only

HP LaserJet Utility

HP Web Jetadmin

Software for Linux

Printing Tasks

Printing Tasks

Guidelines

Selecting the Output Bin

Top Output Bin Rear Output Bin

Printing to the Top Output Bin

Top Output Bin

Printing to the Rear Output Bin

Adjust the Paper Stop

Loading Tray

On the next

Load the tray. For correct orientation, see

Loading the 500-Sheet Tray Optional

Printing Tasks

Printing Both Sides of Paper Optional

Duplexer

Guidelines for Printing Both Sides of Paper

Separating the Printer from the Duplexer

Paper Orientation for Printing Both Sides of Paper

Tray All other trays

Layout Options for Printing Both Sides of Paper

Layout Options for Printing Both Sides of Paper

Printing Letterhead, Prepunched, or

Printing Special Paper

Preprinted Paper

Paper Orientation

Paper Orientation for Tray

Printing Envelopes

Loading Envelopes in Tray

Printing Labels

Do not

Printing Transparencies

Printing Transparencies

Printing Rotated Paper

Tray

Sheet Tray

Printing Rotated Paper from the 500-Sheet Tray

Printing Full-Bleed Images

Printing Cards, Custom-Size and Heavy Paper

Loading Custom-Size Paper in the 500-Sheet Tray

Load the tray

Slide the tray into the printer

Setting Custom Paper Sizes

Guidelines for Printing Custom-Size Paper

Driver, and from the printer’s control panel

Paper is loaded long-edge first X is longer than Y

Printing Tasks

Printing Vellum

Tray 1 MODE=CASSETTE

Using Features in the Printer Driver

Saving Printer Setup Information

Advanced Printing Tasks

Printing with a Watermark

Printing the First Page on Different Paper

Printing Multiple Pages on One Sheet of Paper

Tray 1 Mode=First

Customizing Tray 1 Operation

Tray 1 Mode=Cassette

Feed can also be enabled from the Paper Handling Menu

Manually Feeding Paper from Tray

Printer will print only from Tray

Printer’s control panel

Select the paper size settings from the control panel

Printing by Type and Size of Paper

Benefits of Printing by Type and Size of Paper

To print by type and size of paper, do the following

Size of paper

Type and size settings can also be configured from

Help

Job Retention

Quick Copying a Job

Printing Additional Copies of a Quick Copy Job

Deleting a Stored Quick Copy Job

Printing the Remaining Copies of a Held Job

Proofing and Holding a Job

Deleting a Held Job

Enww

Specifying a Private Job

Printing a Private Job

Releasing a Private Job

Before it is ever printed

Deleting a Private Job

Press Select to select the job. PIN0000 appears

Specifying a Stored Job as Private

Storing a Print Job

Printing a Stored Job

Deleting a Stored Job

Printer Maintenance

Printer Maintenance

Performing Routine Maintenance

Managing the Print Cartridge

HP Policy on Non-HP Print Cartridges

Print Cartridge Storage

Print Cartridge Life Expectancy

Continue Printing When Toner is Low

Redistributing the Toner

Cleaning the Printer

Location of the Transfer Roller-Do Not Touch

Cleaning the Printer

Using the Printer Cleaning

Press Item until Create Cleaning page appears

Problems

Problem Solving

Help you to locate paper jams, properly clear them from

Printer, and solve repeated paper jams

Jams. If paper jams are a recurring problem, see

Clearing Paper Jams

Paper jam is not obvious, look first in the top cover area

Paper jam message

Clearing Jams from the Input Tray Areas

Clearing Jams from the Top Cover Area

Clearing Jams from the Output Areas

Clearing Jams from the Optional Duplexer

Problem Solving

Solving Repeated Paper Jams

If paper jams occur frequently, try the following

Understanding Printer Messages

If a message persists

Self-explanatory

Printer’s control panel page B-13

Not Available

Close TOP Cover

Disk Device

Failure

Install Toner

Flash Device

Flash File

Operation Failed

Changed

JOB Cleared

Simplified

Mopy page TOO

Resend Upgrade

RAM Disk File

Tray 2 Load

Legal

Printer Error

XX.YY

Press GO to Continue

Memory

Paper Size

Fuser Error

41.x

53.xy.zz

56.x

58.x, or

62.x

Cycle Power

Nvram Error

Check Settings

Device Failure

Correcting Output Quality Problems

Problem

Examples below depict letter-size paper that has passed

Vertically rather than horizontally

Troubleshooting Steps

Follow the steps in the order they are listed

Determining Printer Problems

Troubleshooting Flowchart

Macintosh users For more troubleshooting information, see

Ready is

Can you print a configuration page?

Printing Configuration

Can you print from a software application?

Cancel Job might have been pressed

Does the job print as expected?

Does the job print as expected?

Does the printer select the proper trays

Troubleshooting Flowchart for Macintosh Users

To Mac OS

Print job is not sent to the desired printer

Selecting an Alternate PPD

Mac OS 8.6 to Mac OS

Click Select PPD

Mac OS

Linux Problem Solving

Renaming the Printer

Mac OS

Rename the printer

Checking the Printer’s Configuration

Menu Map

Configuration

Options Handling accessories that are installed Toner Level

Event Log

Options

Memory

PCL or PS Font List

To print a PCL or PS font list

Problem Solving

Specifications

Specifications A-1

Paper Specifications

Specifications A-3

Polyester media

Supported Sizes and Weights of Paper

Tray Dimensions1 Weight Capacity2

Specifications A-5

Sheet Tray Dimensions1 Weight Capacity2 Optional

Specifications A-7

Optional Duplex Printing Dimensions1 Weight

Supported Types of Paper

Duplexer

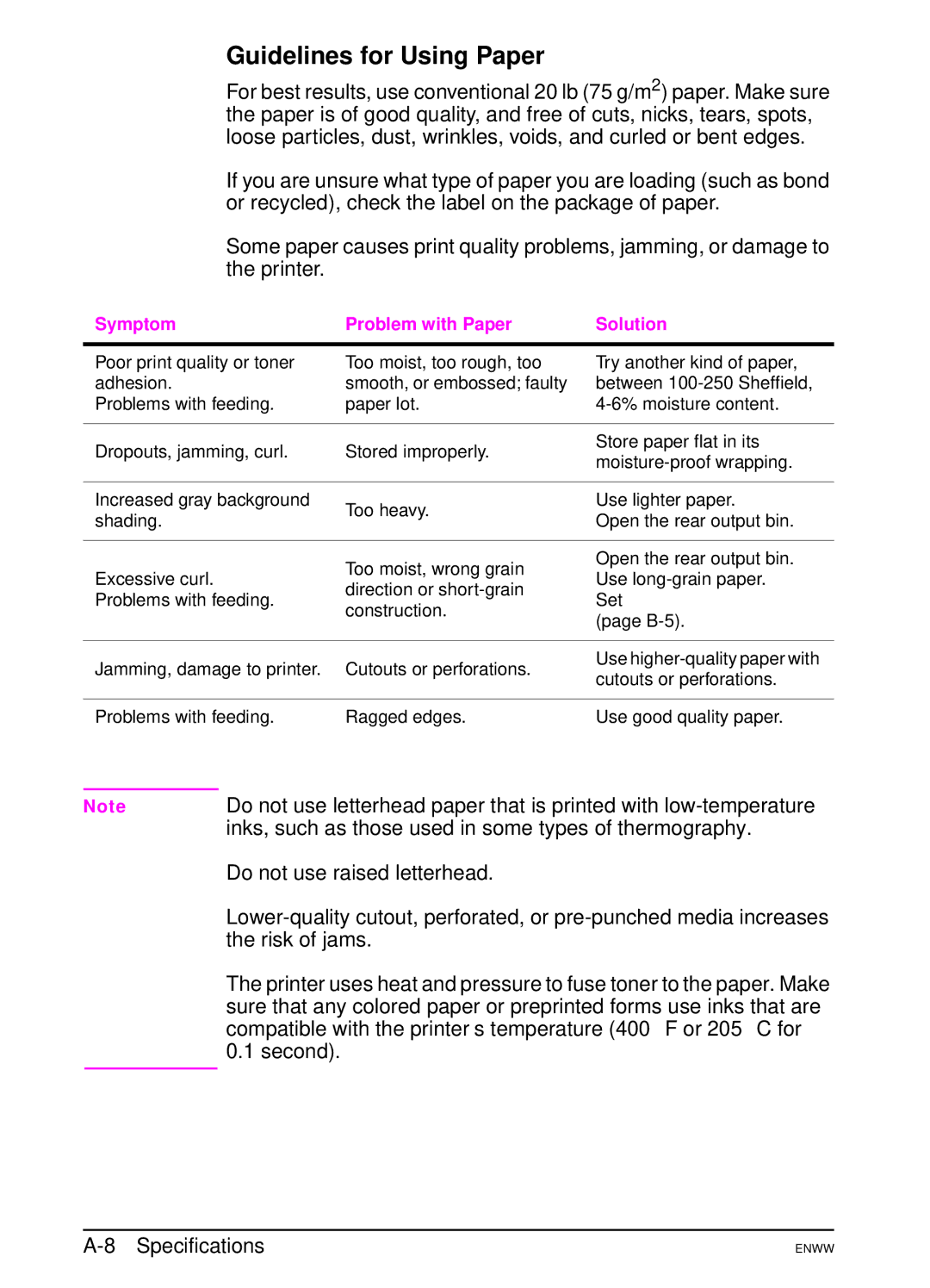

Guidelines for Using Paper

Symptom Problem with Paper Solution

Set Fuser MODE=LOW

Inks, such as those used in some types of thermography

Paper Weight Equivalence Table

Specifications A-9

Transparencies

Labels

Label Construction

Specifications A-11

Vellum

Envelopes

Envelope Construction

Envelopes with Adhesive Strips or Flaps

Envelopes with Double-Side-Seams

Acceptable Unacceptable

Specifications A-13

Card Stock and Heavy Paper

Envelope Margins

Envelope Storage

Card Stock Construction

Card Stock Guidelines

Printer Specifications

Physical Dimensions

Specifications A-15

55 in 139.8 cm 24.6 in 62.5 cm

18.5 in 47.0 cm 10.6 in 27.0 cm 24.4 in 62.0 cm 15.5 cm

Chapter

Printer Weight without print cartridge

18.5 in 47.0 cm 16.6 cm 10.6 in 27.0 cm 29.7 in 75.5 cm

Environmental Specifications

Electrical Specifications

Printer State Power Consumption Average, in watts

Power Requirements Acceptable Line Voltage

Printer State Sound Power1

General Specifications

Acoustic Emissions Per ISO

Chapter

Control Panel Menus

Control Panel Menus B-1

Private/Stored Jobs Menu

Information, see

Displayed on the control panel

Jobname

Information Menu

Control Panel Menus B-3

Paper Handling Menu

Control Panel Menus B-5

Print Quality Menu

Create Cleaning

ECONOMODE=OFF

Toner DENSITY=3

Control Panel Menus B-7

Printing Menu

Control Panel Menus B-9

PCL Symbol

ERRORS=OFF

PCL Font Point

SET=PC-8

Configuration Menu

Control Panel Menus B-11

Resource SAVE= OFF

PCL MEMORY=

400K

PS MEMORY=

Control Panel Menus B-13

JAM RECOVERY= Auto

Maintenance OFF

RAM DISK=AUTO OFF

RAM Disk

Control Panel Menus B-15

Menu

TIMEOUT=15

BUFFER=AUTO Auto

Control Panel Menus B-17

EIO Menu 5100tn/5100dtn

CFG TCP/IP=NO

CFG LINK=NO

Resets Menu

Printer Memory and Expansion

Printer Memory and Expansion C-1

Installing a Dimm

Printer Memory and Expansion

Printer Memory and Expansion C-3

If an optional duplexer is installed

Checking Memory Installation

Resource Saving

Adjusting Memory Settings

To determine how much memory to allocate to a language

To change the I/O Buffer setting

Buffering

Installing EIO Cards/Mass Storage

Installing EIO Cards or Mass Storage Devices

Method for entering printer commands, if needed

Users who are already familiar with PCL command structure

That the printer leave PCL language and enter HP-GL/2 mode

Are printer language switching, job separation, printer

Printer Commands

Understanding PCL Printer Command Syntax

Group

Printer Commands D-3

Combining Escape Sequences

?&l3A?&l1O?&l8D

?&l3a1o8D

Example, if you want a symbol set that contains line-draw

Characters, select the 10U PC-8 or 12U PC-850 symbol set

Selecting PCL Fonts

Others

Common PCL Printer Commands

Printer Commands D-5

?&l#E ?&l#F ?&a#L ?&a#M ?&k#H ?&l#C ?&l#D ?&l#L

?&s#C

?%#A

?%#B

Printer Commands D-7

?s#P ?s#H ?&k#S ?s#V ?s#S ?s#B ?s#T

Printer Commands

To access the embedded Web server

Embedded Web Server E-1

Home Pages

Device Pages

Networking Pages

Adjustable tray

Media. All trays used in the printer are adjustable

Accessories for older printers and the newer EIO

Circuit board that holds extra memory chips for

Software is already installed

Help button or a question mark symbol in the printer

Where paper or other print media is loaded

Printer software help

Index

EIO

Chapter

Chapter

Chapter

??- B-5

Chapter

Chapter

Chapter

Page

Copyright 2002 Hewlett-Packard Company