HP DesignJets 500, 510 and 800 Series Large-Format Printers

Safety Symbols

HP DesignJets 500, 510 and 800 Series Large-Format Printers

Readership Part Numbers

Using this Manual

Purpose

Conventions

Table of Contents

Service Tests and Utilities

Service Calibrations

Parts and Diagrams

Print Quality

Removal and Installation

Glossary Index

Preventive Maintenance

Functional Overview

Troubleshooting

Guide to Troubleshooting the Printer

Introduction

Performing the Necessary Service Calibrations

Troubleshooting System Error Codes

Performing a Service Test on a Failed Assembly

Line Sensor has Problems Detecting Media

Solving Print Quality Problems

Printer does not Power on

Cover Sensors are not Working

Troubleshooting Paper-Axis Shutdowns

Problems with the Vacuum Fan

Vacuum suction much lower at high altitudes

HP-GL/2 color differences in different HP DesignJet Printers

Banding at variable extreme environmental conditions

Priming Procedure Fails

Check for ink

Troubleshooting

Mean that there is a problem with the Printer

Using the Power Switch LED to Troubleshoot

Does not Power up completely. The LED may flash in other

Circumstances which are completely normal and this does not

Page

Using the Boot-Up Sequence to Troubleshoot

Entering Service Menu at Power Up Only for Onsite Repair

LED’s on the Formatter

Using the Formatter/Accessory Card LEDs to Troubleshoot

LED’s on the HP-GL/2 Accessory Card

Page

How to Detect Problems Related to the Encoder Disk

Encoder Disk

System Error Codes

To troubleshoot the problem

Continuable and Non-Continuable Error Codes

System Error Codes Explanation

Even though the customer can continue working with a

System Error Codes

Code Recovery Action Response

Error Log Utility

Accessing the Error Log Utility

To view information on another Error Code, press Back

Front panel will return to the previous screen

System Error Problem Description Corrective Action

0113 Electronics Module failure. The possible cause could be

Error Only applicable to HP DesignJet 500 and 510 Series

Error Only applicable to HP DesignJet 800 Series

Problem Description Corrective Action System Error

Replace the Ink Supply Station ⇒

4110

5610

Front Panel Set-up menu / PS settings / Encoding / Binary

7104

7204

7904

8510

Carriage-Axis shutdown Firmware Error

8613

Ink Supplies Troubleshooting

Magenta and Yellow colors. The HP No.11 Ink Cartridges

What are the Ink Supplies?

Ink Cartridges

Contain 33cc of ink

Printheads

Identifying the Components

General Information About the Ink Supplies

Some General Precautions When Handling the Ink Supplies

When Should You Replace the Ink Cartridges?

When Should You Replace the Printheads?

Worn out Printhead

User can continue using the Printer even with the Printhead

That the Printer is designed to provide, unless he replaces

Obtaining Ink Cartridge Information

Press the Enter key

Obtaining Printhead Information

Front panel displays information on the selected Printhead

Page

Ink Cartridge Status Messages

Ink Cartridge Status While Replacing

Printhead Status Messages

Accessing the Printhead History Utility

Printhead History Utility

Log Printheads Errors Menu Back Enter

Is the Printer Causing Repetitive Printhead Problems?

Summary

Is the User Replacing the Printheads too Early?

Summary

Ink Cartridge is leaking. In this case try the following

Troubleshooting Repetitive Ink Cartridge Messages

Ink Cartridge Error message

Out of Ink message

Expiration message

Troubleshooting Repetitive Printhead Error Messages

Printhead Error message

Order to determine the correct date, the Printer reads

Printhead Error Codes

Code Explanation

Summary of Solving Ink Supplies Problems

Service Tests Utilities

Phone Support

Diagnostics Self Test

Introduction

Initialization Sequences

Service Tests Diagnostics

Instructions on

Entering the Service Tests Menu

Order to enter the Service Utility Menu, please refer to

Page

Ink Supply Station

If this Test PASSES, do not Replace the INK

Carriage Movement

Normal Values Acceptable Values PWM Average

45 mm 65 mm

Lowered before performing this test

Paper Advance Test

Remove any media loaded and make sure that Pinch-Arms are

If the test fails while checking the Paper-Axis Motor, then

Following message will be displayed

You will be able to determine exactly which component failed

Service Utilities

Entering the Service Utilities Menu

Page

Subsystems of the Printer

Eerom Setup

After any change in the EEROM, switch the Printer OFF

If you want to select the Serial Number

B C D E F ES SG

If you want to change the Font Type

If you want to Reset the Usage Counter

Counter for a component when it has not been replaced

Menu

Turn Drive Roller

Operation

Printer to normal operation. Make sure you leave

Unlock Carriage

Carriage will remain uncapped until another action e.g

Carriage in a locked position once the repair is completed

Prime Tubes

Change Cutter

Service Tests and Utilities

To a position where it can be replaced

Change Ink Tubes

Printer Information

Some of the parameters can be reset to zero by using

Eerom Setup utility ⇒

How to convert the Service ID into a calendar date

Page

Service Calibrations

Service Calibrations

Entering the Service Calibrations Menu

Page

Make sure you use HP Bright White InkJet Paper Bond, HP

Printhead Alignment includes PPS Calibration

Perform the Printhead Alignment as follows

Coated Paper, HP Heavy Coated Paper, HP High-Gloss Paper

Aligning printheads Please wait

Color Calibration

Make sure you load media before performing this calibration

Calibration error Press Enter to continue Menu Back

Advance Calibration

Job management menu

Factory Advance Calibration

Do not use any other type of media apart from HP High Gloss

Photo Paper or HP Bright White Inkjet Paper

Job management menu

Print Quality

Print Quality Troubleshooting Checklist

Print Quality

Photo Paper or Bright White InkJet Paper when performing

Accuracy Calibration

Considerations for Using the Troubleshooting Procedure

How to Use the Troubleshooting Procedure

What is the Troubleshooting Procedure?

Performing the Troubleshooting Procedure

Printhead Alignment requires a few centimeters of Paper

Loaded and takes several minutes to perform

Ignore these solid bars

Troubleshooting Procedure Flowchart

Start Here

What to Configure Configuration Setting Optimal Setting

Long Term Color Bleeding Glossy Papers

Solving Color Accuracy problems

Color Consistency problems

Media

There are Smears or Scratching on the Printed Media

Parts and Diagrams

Printer Support

Printer Support

Right Hand Cover

Right Hand Cover

Left Hand Cover

Left Hand Cover

Top Cover and Deflectors

Top Cover and Deflectors

Rollfeed Module

Rollfeed Module

Back Platen Assembly

Back Platen Assembly

Electronics Module

Refer to the following page for more details

Series serial number MY857H307G and greater, and all

Cooling Fan

Cooling fan orientation for the HP DesignJet 500 Printer

HP DesignJet 510 Series Printers, is as shown below

HP Part Number Quantity Description/Comments Drawing

Power Supply

Power Supply

Power Supply

Cutter Assemblies

Cutter Assemblies

Cutter Assemblies

Ink Delivery System

Ink Delivery System

Ink Delivery System

Service Station and Spittoon

Service Station and Spittoon

Service Station and Spittoon

Service Station Holder

Service Station Holder

Service Station Holder

Pinch-Wheel Assemblies

Pinch-Wheel Assemblies

Pinch-Wheel Assemblies

Scan-Axis Motor

Scan-Axis Motor

Scan-Axis Motor

Drive Roller Encoder Sensor

Drive Roller Encoder Sensor

Drive Roller Encoder Sensor

Print Platen Assembly

Print Platen Assembly

Print Platen Assembly

Carriage Assembly

Carriage Assembly

Carriage Assembly

Vacuum Fan

Parts and Diagrams

Vacuum Fan

Vacuum Fan

Interconnect Cable

Interconnect Cable

Interconnect Cable

Paper-Axis Motor

Paper-Axis Motor

Paper-Axis Motor

Drive Roller

Drive Roller

Drive Roller

Miscellaneous Items

Miscellaneous Items

Removal and Installation

Safety Precautions

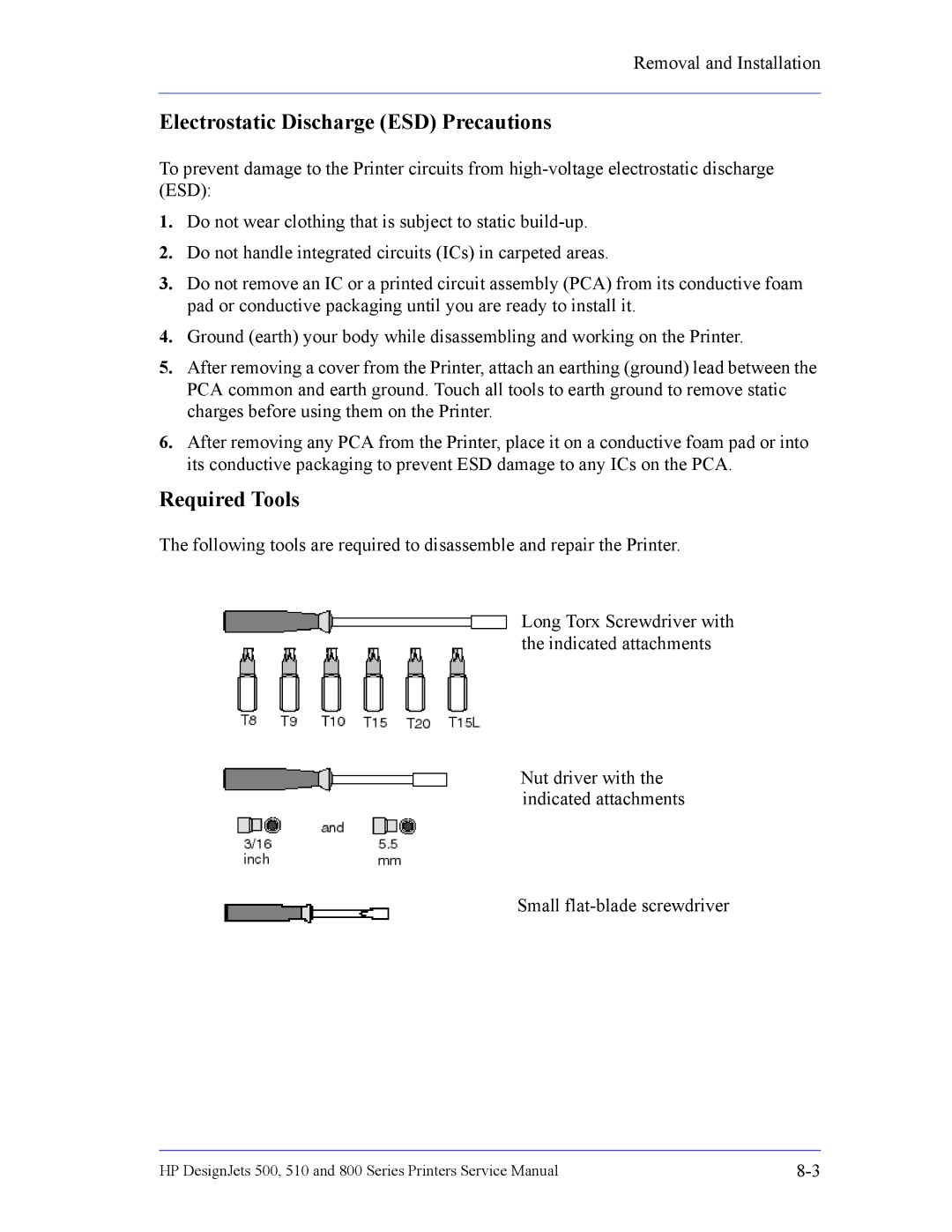

Electrostatic Discharge ESD Precautions

Required Tools

Screw Types

Left Hand Cover

Removal

Page

Back of the Right Hand Cover

Right Hand Cover

Remove 1 T-20 screw Type F from

Page

Front Panel

Window and Top Cover

Switch off the printer and remove the power cord

Media Deflectors

Page

Switch off the printer and remove the power cord

Left End Roll-Feed

Page

Right End Roll-Feed

Removal and Installation Remove Right Hand Roll-Feed

Back Platen

Page

Media Sensor

Back of the Left Hand Cover

Formatter

Remove the LAN Card Cover from

LAN Card

Page

Spittoon

Release

Disconnect ALL the cables from

Electronics Module

Remove the Left Hand Cover Refer

Loosen Only

Installing the Electronics Module

Power Supply

Disconnect

Page

Scan-Axis Motor Assembly

Page

Installing the Scan-Axis Motor

From the Front Panel Menu

Cutter Assembly

Select the Change Cutter option

Open the Window

Left Encoder Holder

Page

Cutter Bushing

Cutter Guide Bracket

Remove the Cutter from its position

Page

Drive Roller Encoder Sensor

Page

Trailing Cable

Page

Page

Page

Page

Page

Page

Installing the Trailing Cable

Ink Supply Station

Installed together

Assembly that includes

Assembly must be removed

ISS is a complete

Disconnect all the cables connected to

Interconnect PCA

Remove the Right Hand Cover Refer

Interconnect PCA

Page

Service Station and Aerosol Fan

Page

Installing the Service Station/Aerosol Fan

Cutter Guide

Print Platen

Service Station Holder

Page

Interconnect Cable

Ink Supply Tubes

Page

Page

Page

Vacuum Fan

Page

Pinch-Arm

Pinch-Arm Mechanism

Page

Pinch-Arm Lever

Page

Pinch-Arm Sensor

Raise the Media Lever

Page

Page

Fork Idler, Tensioner and Idler Pulley

Page

Encoder Strip

Release

Carriage Assembly Including Belt

Page

Page

Page

Page

Installing the Carriage Assembly

Paper-Axis Motor

Page

Drive Roller

Page

Page

Page

Page

Page

Gear Assemblies

Page

Preventive Maintenance

Preventive Maintenance

Level of Printer Usage

Cleaning the Drive Roller/Print Platen

Scheduled Maintenance

Scan-Axis Maintenance

Functional Overview

SKU Overview

Total there are 12 SKUs. They are detailed as follows

Functional Overview

Electrical System

Hardware Description

Page

Power Supply Unit PSU

Power Supply Connector to Main PCA Power Switch Housing

Front Panel

Voltage Maximum Output Systems

Ink Delivery System IDS

Ink Supply Station ISS

10-9

Tubes Assembly

Tubes System ISS Crane Clips Carriage Crane

Service Station

Application

Default

Ansi size

Centronics

Input/output

Margin

Matte

Inked area

Platen

Raster

Pen

Printing area

About this Edition

Large-Format Printers

Index

Page

Page