Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

INSTALLATION

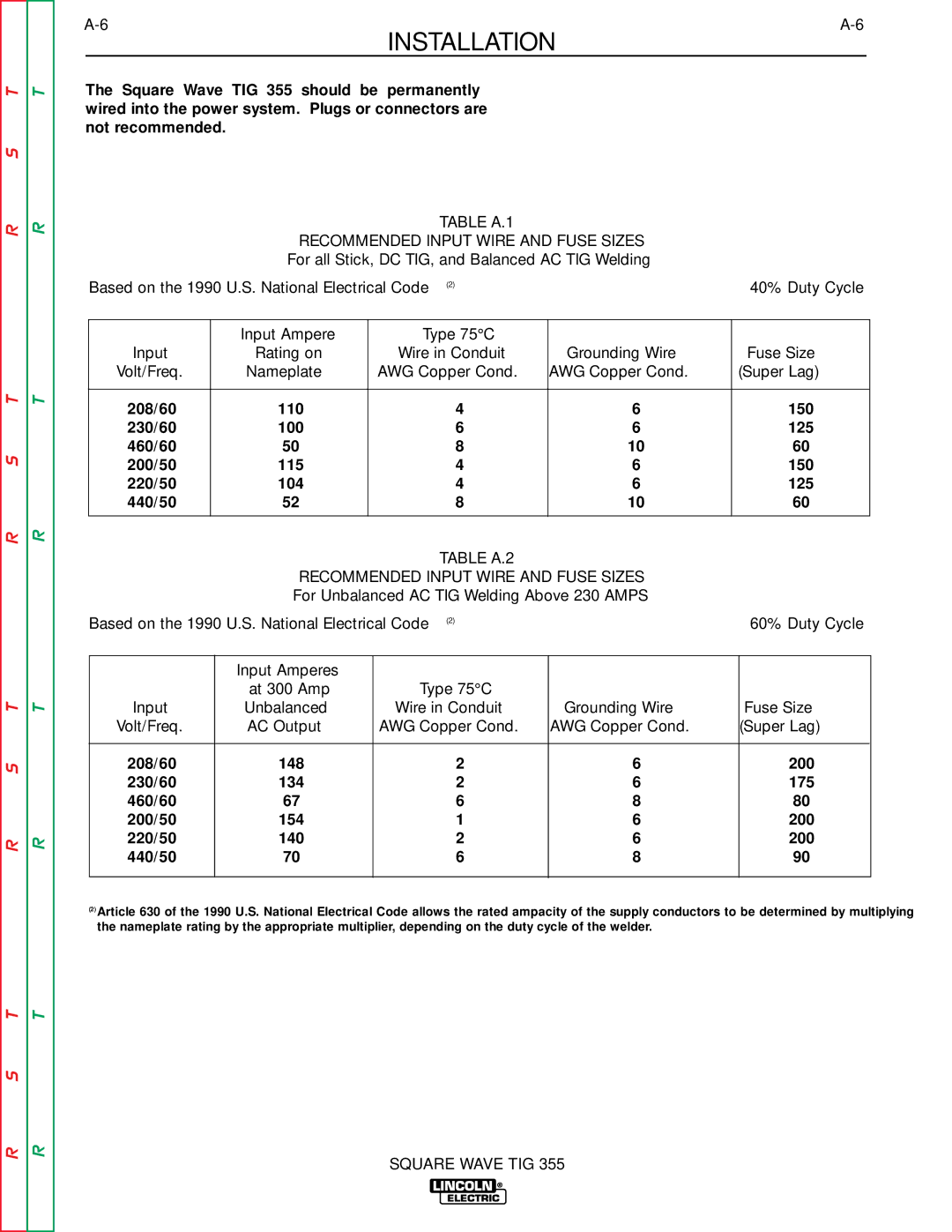

The Square Wave TIG 355 should be permanently wired into the power system. Plugs or connectors are not recommended.

TABLE A.1

RECOMMENDED INPUT WIRE AND FUSE SIZES

For all Stick, DC TIG, and Balanced AC TIG Welding

Based on the 1990 U.S. National Electrical Code(2) |

| 40% Duty Cycle | ||

|

|

|

|

|

| Input Ampere | Type 75°C |

|

|

Input | Rating on | Wire in Conduit | Grounding Wire | Fuse Size |

Volt/Freq. | Nameplate | AWG Copper Cond. | AWG Copper Cond. | (Super Lag) |

|

|

|

|

|

208/60 | 110 | 4 | 6 | 150 |

230/60 | 100 | 6 | 6 | 125 |

460/60 | 50 | 8 | 10 | 60 |

200/50 | 115 | 4 | 6 | 150 |

220/50 | 104 | 4 | 6 | 125 |

440/50 | 52 | 8 | 10 | 60 |

|

|

|

|

|

TABLE A.2

RECOMMENDED INPUT WIRE AND FUSE SIZES

For Unbalanced AC TIG Welding Above 230 AMPS

Based on the 1990 U.S. National Electrical Code(2) |

| 60% Duty Cycle | ||

|

|

|

|

|

| Input Amperes |

|

|

|

| at 300 Amp | Type 75°C |

|

|

Input | Unbalanced | Wire in Conduit | Grounding Wire | Fuse Size |

Volt/Freq. | AC Output | AWG Copper Cond. | AWG Copper Cond. | (Super Lag) |

|

|

|

|

|

208/60 | 148 | 2 | 6 | 200 |

230/60 | 134 | 2 | 6 | 175 |

460/60 | 67 | 6 | 8 | 80 |

200/50 | 154 | 1 | 6 | 200 |

220/50 | 140 | 2 | 6 | 200 |

440/50 | 70 | 6 | 8 | 90 |

|

|

|

|

|

(2)Article 630 of the 1990 U.S. National Electrical Code allows the rated ampacity of the supply conductors to be determined by multiplying the nameplate rating by the appropriate multiplier, depending on the duty cycle of the welder.

SQUARE WAVE TIG 355