Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

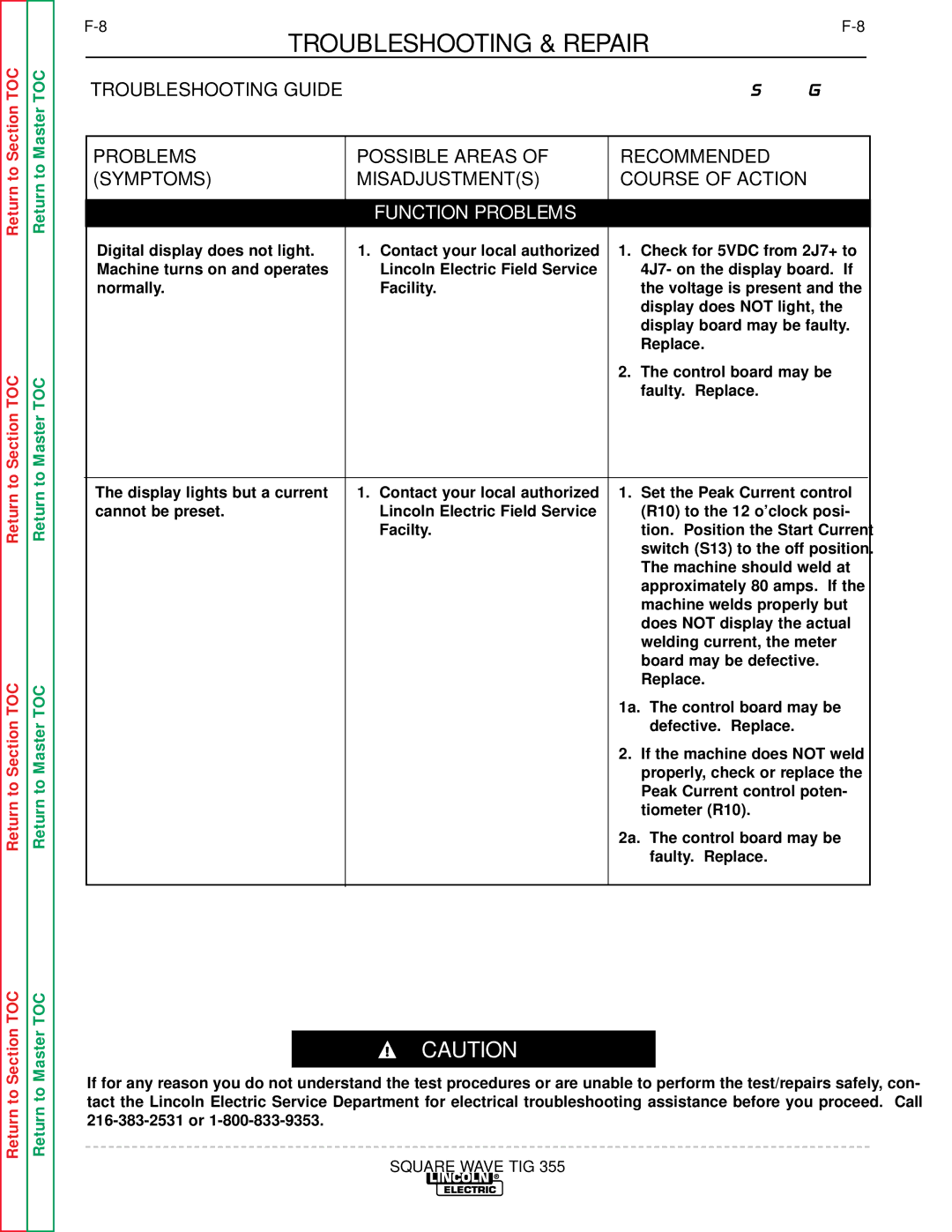

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

| FUNCTION PROBLEMS |

|

Digital display does not light. | 1. Contact your local authorized | 1. Check for 5VDC from 2J7+ to |

Machine turns on and operates | Lincoln Electric Field Service | 4J7- on the display board. If |

normally. | Facility. | the voltage is present and the |

|

| display does NOT light, the |

|

| display board may be faulty. |

|

| Replace. |

|

| 2. The control board may be |

|

| faulty. Replace. |

The display lights but a current | 1. Contact your local authorized | 1. Set the Peak Current control |

cannot be preset. | Lincoln Electric Field Service | (R10) to the 12 o’clock posi- |

| Facilty. | tion. Position the Start Current |

|

| switch (S13) to the off position. |

|

| The machine should weld at |

|

| approximately 80 amps. If the |

|

| machine welds properly but |

|

| does NOT display the actual |

|

| welding current, the meter |

|

| board may be defective. |

|

| Replace. |

|

| 1a. The control board may be |

|

| defective. Replace. |

|

| 2. If the machine does NOT weld |

|

| properly, check or replace the |

|

| Peak Current control poten- |

|

| tiometer (R10). |

|

| 2a. The control board may be |

|

| faulty. Replace. |

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

SQUARE WAVE TIG 355