Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

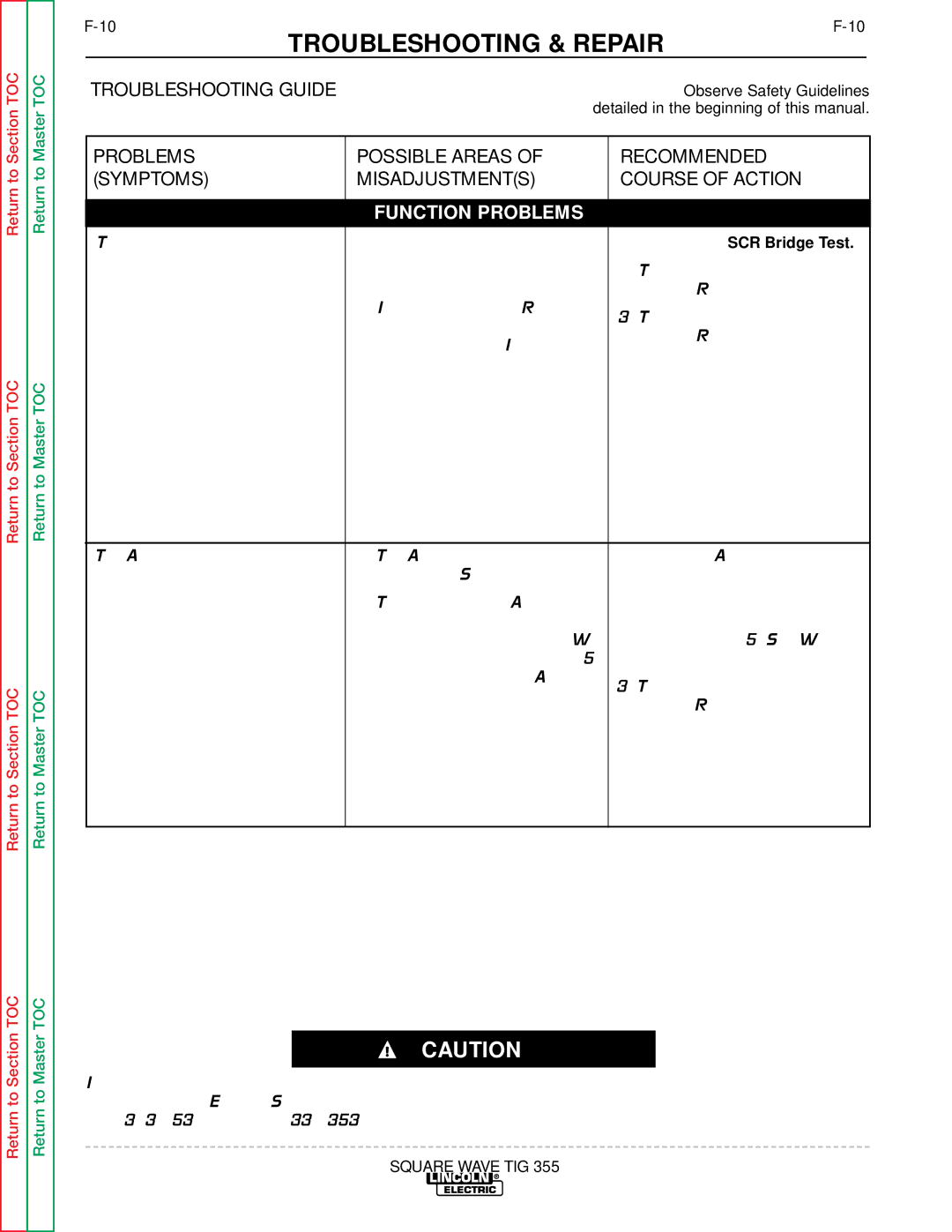

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |

|

|

| |

| FUNCTION PROBLEMS |

| |

The machine welds at very high | 1. Make sure the start controls | 1. Perform the SCR Bridge Test. | |

outputs, regardless of the Peak | are set correctly for the | 2. The power board may be | |

Current control setting. | process being used. | ||

faulty. Replace. | |||

|

| ||

| 2. If the machine is in Remote | 3. The control board may be | |

| control mode, change modes | ||

| faulty. Replace. | ||

| to Local control. If the prob- | ||

|

| ||

| lem is resolved, the remote |

| |

| control unit may be defective. |

|

The Arc Force control has no | 1. The Arc Force control is active | 1. | Check the Arc Force control |

effect on the arc. | only in the Stick mode. |

| potentiometer for correct resis- |

| 2. The effect of the Arc Force |

| tance and proper operation. |

|

|

| |

| control will be less noticeable | 2. | Check the continuity of leads |

| at high welding currents. Weld |

| #441 and #445. See Wiring |

| at low currents (less than 150 |

| Diagram. |

| amps) and check the Arc Force | 3. | The control board may be |

| control function. | ||

|

| faulty. Replace. | |

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

SQUARE WAVE TIG 355