Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

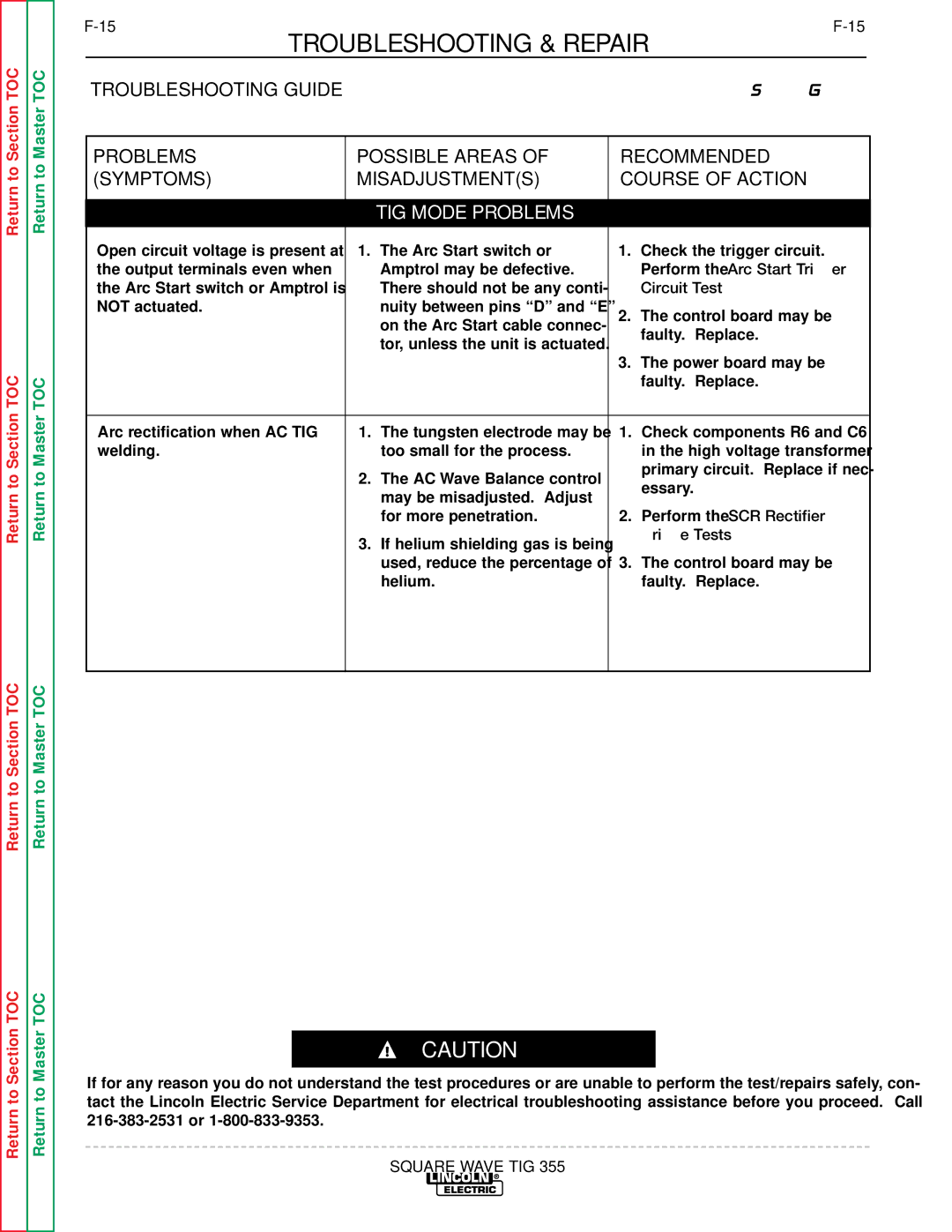

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | ||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | ||

|

|

|

|

|

|

| TIG MODE PROBLEMS |

|

|

Open circuit voltage is present at | 1. | The Arc Start switch or | 1. | Check the trigger circuit. |

the output terminals even when |

| Amptrol may be defective. |

| Perform the Arc Start Trigger |

the Arc Start switch or Amptrol is |

| There should not be any conti- |

| Circuit Test. |

NOT actuated. |

| nuity between pins “D” and “E” | 2. The control board may be | |

|

| on the Arc Start cable connec- | ||

|

|

| faulty. Replace. | |

|

| tor, unless the unit is actuated. |

| |

|

|

|

| |

|

|

| 3. The power board may be | |

|

|

|

| faulty. Replace. |

|

|

|

|

|

Arc rectification when AC TIG | 1. | The tungsten electrode may be | 1. | Check components R6 and C6 |

welding. |

| too small for the process. |

| in the high voltage transformer |

| 2. The AC Wave Balance control |

| primary circuit. Replace if nec- | |

|

| essary. | ||

|

| may be misadjusted. Adjust |

| |

|

|

|

| |

|

| for more penetration. | 2. | Perform the SCR Rectifier |

| 3. If helium shielding gas is being |

| Bridge Tests. | |

|

|

| ||

|

| used, reduce the percentage of | 3. | The control board may be |

|

| helium. |

| faulty. Replace. |

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

SQUARE WAVE TIG 355