Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

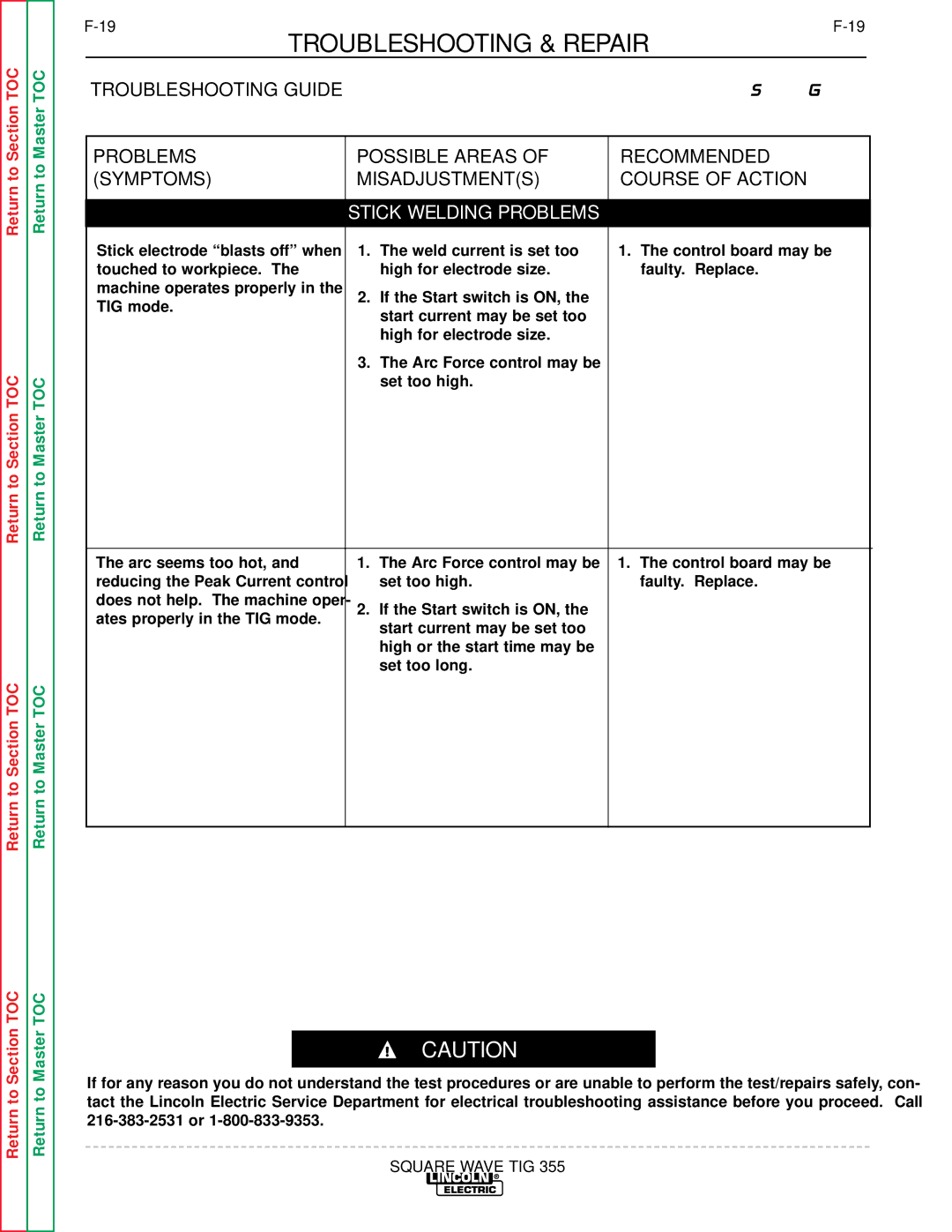

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |

|

|

| |

| STICK WELDING PROBLEMS |

| |

Stick electrode “blasts off” when | 1. | The weld current is set too | 1. The control board may be |

touched to workpiece. The |

| high for electrode size. | faulty. Replace. |

machine operates properly in the | 2. | If the Start switch is ON, the |

|

TIG mode. |

| ||

| start current may be set too |

| |

|

|

| |

|

| high for electrode size. |

|

| 3. | The Arc Force control may be |

|

|

| set too high. |

|

The arc seems too hot, and | 1. | The Arc Force control may be | 1. The control board may be |

reducing the Peak Current control |

| set too high. | faulty. Replace. |

does not help. The machine oper- | 2. | If the Start switch is ON, the |

|

ates properly in the TIG mode. |

| ||

| start current may be set too |

| |

|

|

| |

|

| high or the start time may be |

|

|

| set too long. |

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

SQUARE WAVE TIG 355