Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

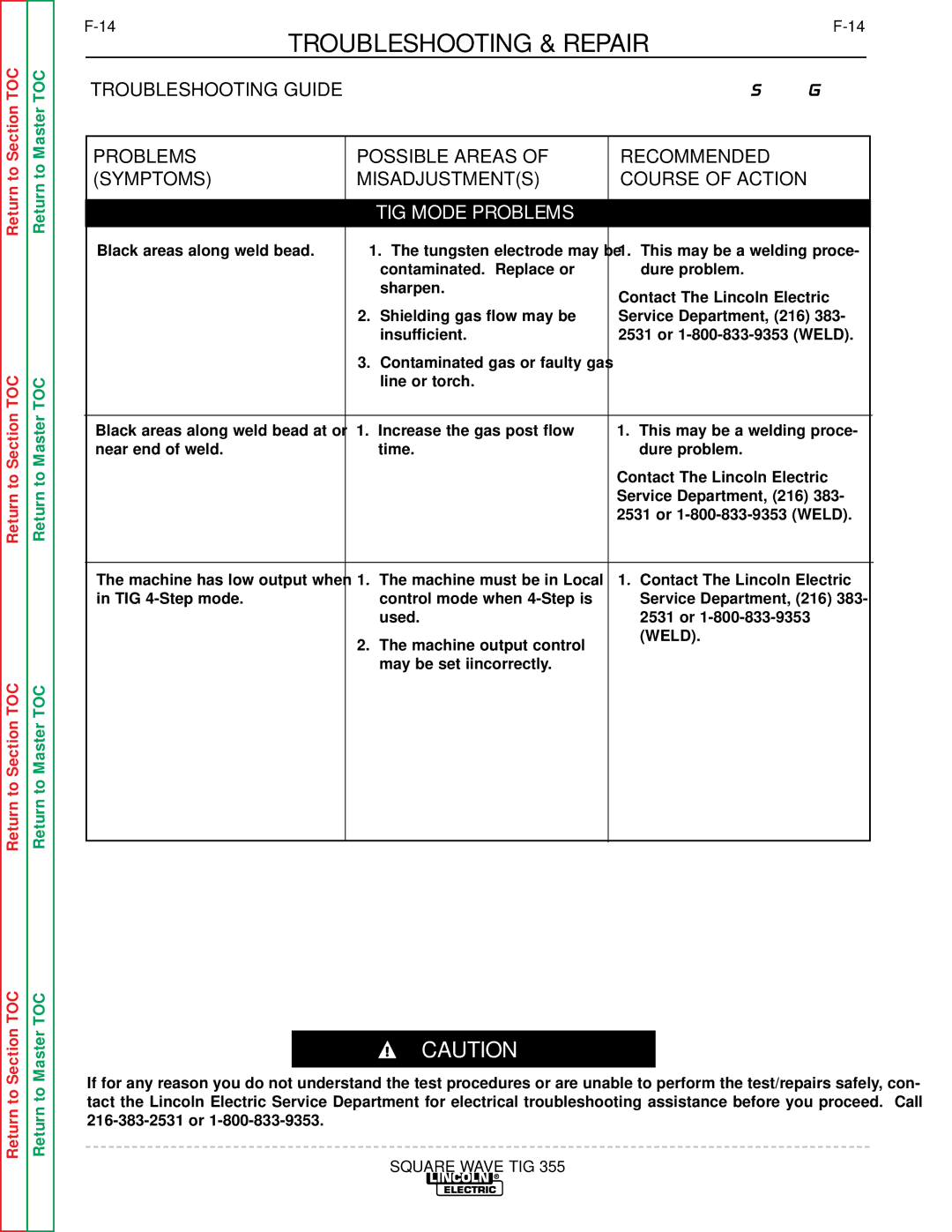

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| |

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

| |

|

|

|

|

|

|

|

|

| TIG MODE PROBLEMS |

|

|

| Black areas along weld bead. | 1. | The tungsten electrode may be | 1. This may be a welding proce- |

|

|

|

| contaminated. Replace or | dure problem. |

|

|

|

| sharpen. | Contact The Lincoln Electric |

|

|

|

|

|

| |

|

| 2. | Shielding gas flow may be | Service Department, (216) 383- |

|

|

|

| insufficient. | 2531 or |

|

|

| 3. | Contaminated gas or faulty gas |

|

|

|

|

| line or torch. |

|

|

|

|

|

|

|

|

| Black areas along weld bead at or | 1. | Increase the gas post flow | 1. This may be a welding proce- |

|

| near end of weld. |

| time. | dure problem. |

|

|

|

|

| Contact The Lincoln Electric |

|

|

|

|

| Service Department, (216) 383- |

|

|

|

|

| 2531 or |

|

|

|

|

|

|

|

| The machine has low output when | 1. | The machine must be in Local | 1. Contact The Lincoln Electric |

|

| in TIG |

| control mode when | Service Department, (216) 383- |

|

|

|

| used. | 2531 or |

|

|

| 2. | The machine output control | (WELD). |

|

|

|

|

| ||

|

|

| may be set iincorrectly. |

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

SQUARE WAVE TIG 355