Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

THEORY OF OPERATION

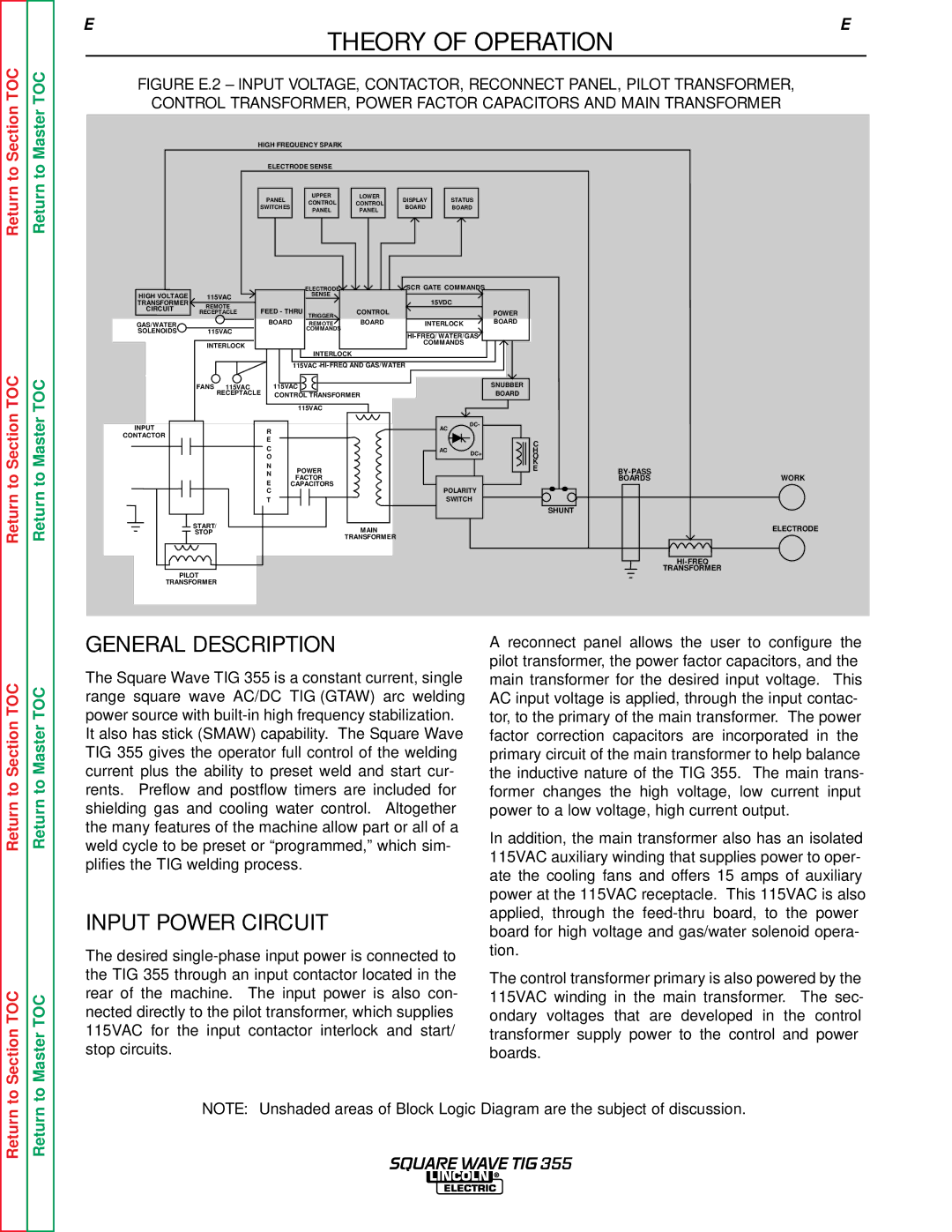

FIGURE E.2 – INPUT VOLTAGE, CONTACTOR, RECONNECT PANEL, PILOT TRANSFORMER, CONTROL TRANSFORMER, POWER FACTOR CAPACITORS AND MAIN TRANSFORMER

HIGH FREQUENCY SPARK

ELECTRODE SENSE

PANEL | UPPER |

|

| LOWER |

| DISPLAY |

| STATUS | |

CONTROL |

| CONTROL |

|

| |||||

SWITCHES |

|

| BOARD |

| BOARD | ||||

PANEL |

|

| PANEL |

|

| ||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ELECTRODE |

| SCR GATE COMMANDS |

|

HIGH VOLTAGE | 115VAC |

| SENSE |

| 15VDC |

|

TRANSFORMER | REMOTE |

|

|

|

| |

CIRCUIT | FEED - THRU | CONTROL |

| POWER | ||

| RECEPTACLE |

| ||||

|

| BOARD | TRIGGER | BOARD |

| BOARD |

GAS/WATER |

| REMOTE | INTERLOCK | |||

SOLENOIDS | 115VAC |

| COMMANDS |

|

|

|

|

|

|

| |||

|

|

|

|

|

| |

| INTERLOCK |

|

|

| COMMANDS |

|

|

|

|

|

|

| |

|

|

| INTERLOCK |

|

|

|

|

|

| 115VAC |

|

| |

| FANS 115VAC | 115VAC |

|

| SNUBBER | |

| RECEPTACLE | CONTROL TRANSFORMER |

| BOARD | ||

|

|

| 115VAC |

|

|

|

INPUT | R |

| AC | DC- |

|

|

|

|

|

|

|

| |||

CONTACTOR |

|

|

|

|

|

| |

E |

|

|

|

|

|

| |

|

|

|

| C |

|

| |

| C |

|

|

|

|

| |

|

| AC | DC+ | H |

|

| |

| O |

|

| O |

|

| |

| N |

|

|

| K |

|

|

| POWER |

|

| E |

| ||

| N |

|

|

| WORK | ||

| E | FACTOR |

|

|

| BOARDS | |

| CAPACITORS | POLARITY |

|

|

| ||

| C |

|

|

|

| ||

| T |

| SWITCH |

|

|

| |

|

|

|

|

|

| SHUNT |

|

| START/ | MAIN |

|

|

|

| ELECTRODE |

| STOP |

|

|

|

| ||

|

| TRANSFORMER |

|

|

|

|

|

|

|

|

|

|

|

| |

| PILOT |

|

|

|

|

| TRANSFORMER |

|

|

|

|

|

|

| |

| TRANSFORMER |

|

|

|

|

|

|

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

GENERAL DESCRIPTION

The Square Wave TIG 355 is a constant current, single range square wave AC/DC TIG (GTAW) arc welding power source with

INPUT POWER CIRCUIT

The desired

A reconnect panel allows the user to configure the pilot transformer, the power factor capacitors, and the main transformer for the desired input voltage. This AC input voltage is applied, through the input contac- tor, to the primary of the main transformer. The power factor correction capacitors are incorporated in the primary circuit of the main transformer to help balance the inductive nature of the TIG 355. The main trans- former changes the high voltage, low current input power to a low voltage, high current output.

In addition, the main transformer also has an isolated 115VAC auxiliary winding that supplies power to oper- ate the cooling fans and offers 15 amps of auxiliary power at the 115VAC receptacle. This 115VAC is also applied, through the

The control transformer primary is also powered by the 115VAC winding in the main transformer. The sec- ondary voltages that are developed in the control transformer supply power to the control and power boards.

Return

Return

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

SQUARE WAVE TIG 355