Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

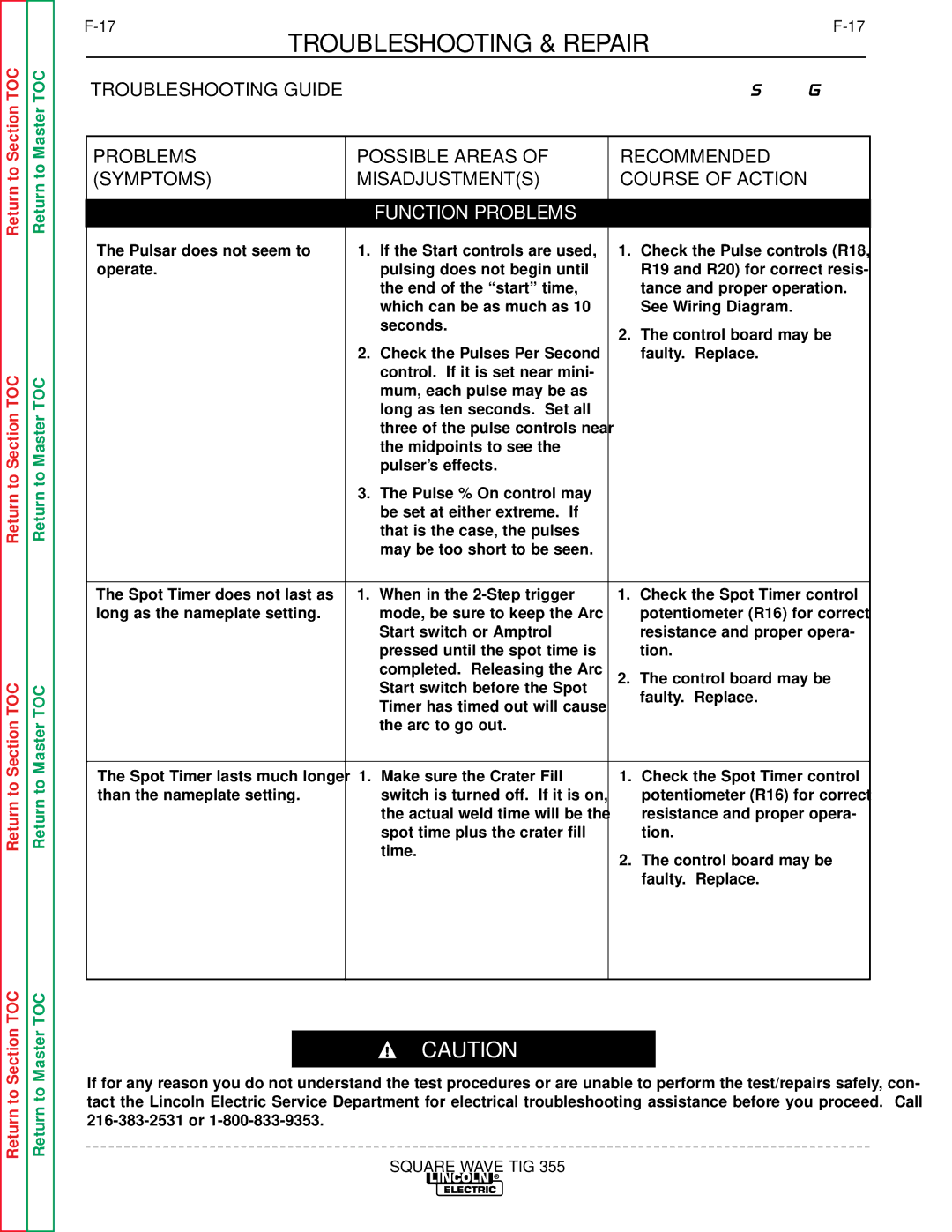

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | ||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | ||

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

The Pulsar does not seem to | 1. | If the Start controls are used, | 1. | Check the Pulse controls (R18, |

operate. |

| pulsing does not begin until |

| R19 and R20) for correct resis- |

|

| the end of the “start” time, |

| tance and proper operation. |

|

| which can be as much as 10 |

| See Wiring Diagram. |

|

| seconds. | 2. The control board may be | |

|

|

| ||

| 2. | Check the Pulses Per Second |

| faulty. Replace. |

|

| control. If it is set near mini- |

|

|

|

| mum, each pulse may be as |

|

|

|

| long as ten seconds. Set all |

|

|

|

| three of the pulse controls near |

|

|

|

| the midpoints to see the |

|

|

|

| pulser’s effects. |

|

|

| 3. The Pulse % On control may |

|

| |

|

| be set at either extreme. If |

|

|

|

| that is the case, the pulses |

|

|

|

| may be too short to be seen. |

|

|

|

|

|

|

|

The Spot Timer does not last as | 1. | When in the | 1. | Check the Spot Timer control |

long as the nameplate setting. |

| mode, be sure to keep the Arc |

| potentiometer (R16) for correct |

|

| Start switch or Amptrol |

| resistance and proper opera- |

|

| pressed until the spot time is |

| tion. |

|

| completed. Releasing the Arc | 2. The control board may be | |

|

| Start switch before the Spot | ||

|

|

| faulty. Replace. | |

|

| Timer has timed out will cause |

| |

|

|

|

| |

|

| the arc to go out. |

|

|

|

|

|

|

|

The Spot Timer lasts much longer | 1. | Make sure the Crater Fill | 1. | Check the Spot Timer control |

than the nameplate setting. |

| switch is turned off. If it is on, |

| potentiometer (R16) for correct |

|

| the actual weld time will be the |

| resistance and proper opera- |

|

| spot time plus the crater fill |

| tion. |

|

| time. | 2. The control board may be | |

|

|

| ||

|

|

|

| faulty. Replace. |

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

SQUARE WAVE TIG 355