Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

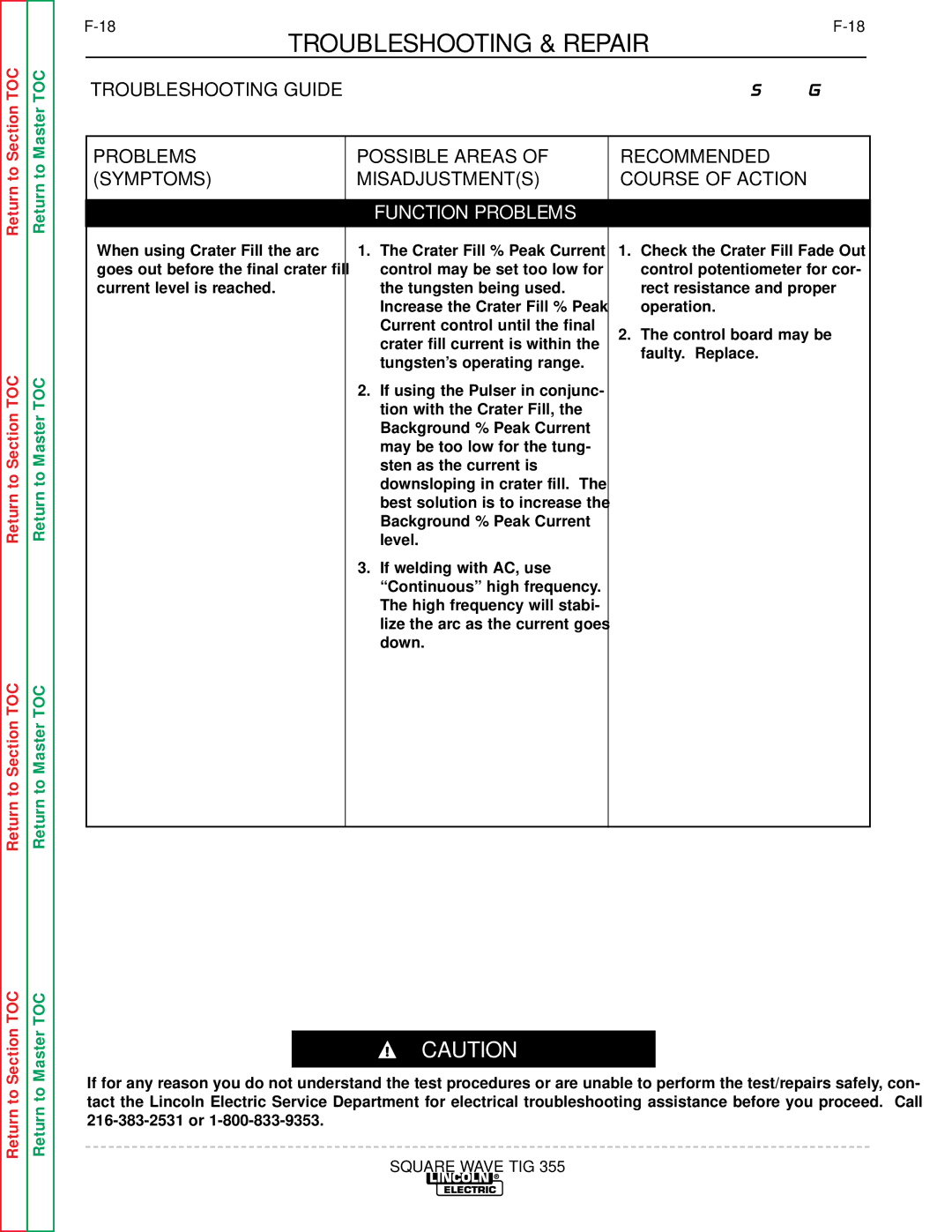

| TROUBLESHOOTING & REPAIR |

| |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

| FUNCTION PROBLEMS |

|

When using Crater Fill the arc | 1. The Crater Fill % Peak Current | 1. Check the Crater Fill Fade Out |

goes out before the final crater fill | control may be set too low for | control potentiometer for cor- |

current level is reached. | the tungsten being used. | rect resistance and proper |

| Increase the Crater Fill % Peak | operation. |

| Current control until the final | 2. The control board may be |

| crater fill current is within the | |

| faulty. Replace. | |

| tungsten’s operating range. | |

|

| |

| 2. If using the Pulser in conjunc- |

|

| tion with the Crater Fill, the |

|

| Background % Peak Current |

|

| may be too low for the tung- |

|

| sten as the current is |

|

| downsloping in crater fill. The |

|

| best solution is to increase the |

|

| Background % Peak Current |

|

| level. |

|

| 3. If welding with AC, use |

|

| “Continuous” high frequency. |

|

| The high frequency will stabi- |

|

| lize the arc as the current goes |

|

| down. |

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

SQUARE WAVE TIG 355