TOC TOC

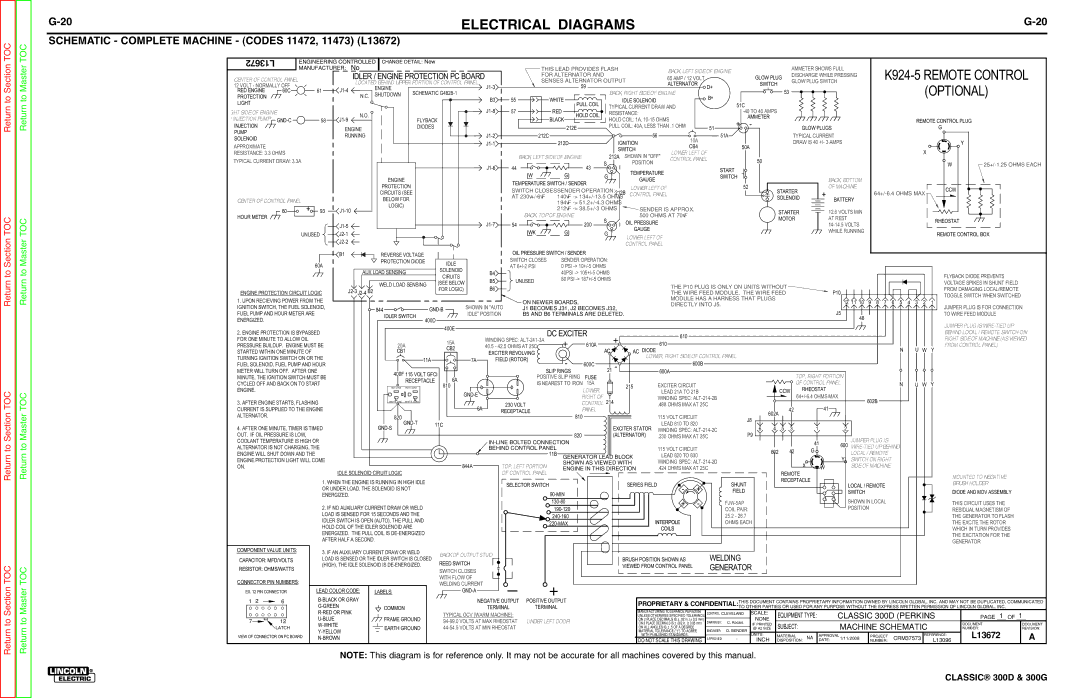

ELECTRICAL DIAGRAMS | ||

SCHEMATIC - COMPLETE MACHINE - (CODES 11472, 11473) (L13672) |

|

|

Return to Section Return to Master

L13672 |

| ENGINEERING CONTROLLED CHANGE DETAIL: New | |||||

| MANUFACTURER: No |

|

| ||||

|

|

|

| ||||

CENTER OF CONTROL PANEL |

|

| IDLER / ENGINE PROTECTION PC BOARD | ||||

|

| LOCATED BEHIND UPPER PORTION OF CONTROL PANEL | |||||

12 VOLT - NORMALLY OFF |

|

| |||||

RED ENGINE | 60C | 61 |

| ENGINE | SCHEMATIC | ||

N.C. | SHUTDOWN | ||||||

PROTECTION |

|

|

| ||||

|

|

|

| ||||

LIGHT |

|

|

|

|

|

| |

GHT SIDEOF ENGINE | 58 | N.O. |

| FLYBACK | |||

YINJECTION PUMP |

|

| |||||

INJECTION |

|

| ENGINE |

| DIODES | ||

PUMP |

|

|

|

| |||

|

| RUNNING |

|

| |||

SOLENOID |

|

|

|

| |||

|

|

|

|

|

| ||

APPROXIMATE |

|

|

|

|

|

| |

RESISTANCE: 3.3 OHMS |

|

|

|

|

| ||

|

| THIS LEAD PROVIDES FLASH |

| BACK, LEFT SIDEOF ENGINE |

|

| AMMETER SHOWS FULL | |||

|

| FOR ALTERNATOR AND |

|

|

| GLOW PLUG | DISCHARGE WHILE PRESSING | |||

|

|

|

| 65 AMP / 12 VOLT |

|

| ||||

|

| SENSES ALTERNATOR OUTPUT |

|

| GLOW PLUG SWITCH | |||||

|

| ALTERNATOR |

|

| SWITCH | |||||

|

| 59 |

|

| D+ |

|

| |||

|

| BACK, RIGHT SIDEOF ENGINE |

|

| 53 | |||||

B3 | 55 | WHITE |

| B+ |

|

| ||||

PULL COIL |

| IDLE SOLENOID |

|

|

|

| ||||

|

|

| 51C |

| ||||||

57 | RED | TYPICAL CURRENT DRAW AND |

|

| ||||||

HOLD COIL | RESISTANCE: |

|

|

|

| |||||

|

|

|

|

|

| AMMETER |

| |||

|

| BLACK | HOLD COIL: 1A, |

|

|

| ||||

|

|

|

| + | - |

| ||||

|

|

| 212E | PULL COIL: 40A, LESS THAN .1 OHM | 51 | GLOW PLUGS | ||||

|

|

|

|

|

|

|

| |||

| 212C |

|

| 56 | 10A | 51A |

|

| TYPICAL CURRENT | |

| 212D | IGNITION |

|

|

| DRAW IS 40 +/- 3 AMPS | ||||

| CB4 |

|

| 50A | ||||||

|

|

|

| SWITCH |

|

|

| |||

|

|

|

| LOWER LEFT OF |

|

|

|

| ||

|

| BACK, LEFT SIDEOF ENGINE | 212A | SHOWN IN "OFF" |

|

|

|

| ||

|

| CONTROL PANEL |

|

|

| |||||

K924-5 REMOTE CONTROL

(OPTIONAL)

REMOTE CONTROL PLUG

G

Y

X

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

TYPICAL CURRENT DRAW: 3.3A |

50 |

|

|

| ENGINE |

|

|

| PROTECTION |

|

|

| CIRCUITS (SEE |

CENTER OF CONTROL PANEL |

|

| BELOW FOR |

+ |

| LOGIC) | |

|

| ||

60 | 93 | ||

HOUR METER |

|

|

|

44 | 43 | S | I | POSITION |

|

|

|

| |

| TEMPERATURE | START |

|

|

| ||||

| W | G | G |

|

|

|

| ||

|

| SWITCH |

|

| BACK, BOTTOM | ||||

|

| GAUGE |

|

| |||||

| TEMPERATURE SWITCH / SENDER |

|

|

|

|

| |||

|

|

| LOWER LEFT OF | 52 |

|

| OF MACHINE | ||

| SWITCH CLOSESSENDER OPERATION: |

| STARTER | + | |||||

|

| CONTROL PANEL |

|

| |||||

| AT | 140vF |

| SOLENOID | BATTERY | ||||

|

| 194vF |

|

|

|

| |||

|

|

|

|

|

|

| |||

|

| 212vF |

| SENDER IS APPROX. |

| STARTER |

| 12.6 VOLTS MIN | |

| BACK, TOPOF ENGINE |

|

| 500 OHMS AT 70vF |

|

| |||

|

|

|

|

|

| AT REST | |||

W

CCW

| |

UNUSED | |

|

| 200 | S | I | OIL PRESSURE | MOTOR | ||

54 | |||||||

| |||||||

| WK | G | G |

| GAUGE | WHILE RUNNING | |

|

| LOWER LEFT OF | |||||

|

|

|

|

|

| ||

|

|

|

|

| CONTROL PANEL |

|

RHEOSTAT

REMOTE CONTROL BOX

|

| B1 |

| REVERSE VOLTAGE |

|

|

|

|

| OIL PRESSURE SWITCH / SENDER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| 60A |

| PROTECTION DIODE |

| IDLE |

|

| SWITCH CLOSES | SENDER OPERATION: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| AT | 0 PSI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| AUX LOAD SENSING |

|

| SOLENOID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

| B4 |

|

| 40PSI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FLYBACK DIODE PREVENTS |

| ||||||

|

|

|

|

|

| CIRUITS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

| B5 | UNUSED | 80 PSI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

| WELD LOAD SENSING |

| (SEE BELOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| VOLTAGE SPIKES IN SHUNT FIELD | ||||||||||

|

|

|

|

|

|

|

| THE P10 PLUG IS ONLY ON UNITS WITHOUT |

|

|

|

|

|

|

|

|

|

| |||||||||||||||||

|

|

|

|

| B6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

|

|

|

|

| FOR LOGIC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FROM DAMAGING LOCAL/REMOTE | ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

ENGINE PROTECTION CIRCUIT LOGIC |

|

|

|

|

|

|

|

| THE WIRE FEED MODULE. THE WIRE FEED |

|

|

| P10 |

|

|

|

|

| |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TOGGLE SWITCH WHEN SWITCHED | ||||||||||||||||

1. UPON RECIEVING POWER FROM THE |

|

|

|

|

|

|

|

|

|

|

|

|

| MODULE HAS A HARNESS THAT PLUGS |

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

| ON NEWER BOARDS, |

|

|

|

|

|

|

| 12 11 10 | 9 8 7 | 6 5 4 | 3 | 2 | 1 |

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

| DIRECTLY INTO J5. |

|

|

|

|

|

|

|

|

|

| ||||||||||||||

IGNITION SWITCH, THE FUEL SOLENOID, |

| 844 |

| SHOWN IN "AUTO | J1 BECOMES J31, J2 BECOMES J32, |

|

|

|

|

|

|

|

|

|

|

|

|

|

| JUMPER PLUG IS FOR CONNECTION | |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| J5 |

|

|

|

|

| ||||||||||||||||||

FUEL PUMP AND HOUR METER ARE |

|

|

| IDLE" POSITION | B5 AND B6 TERMINALS ARE DELETED. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TO WIRE FEED MODULE |

| |||||||||||||

|

| IDLER SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

| 48 |

|

|

|

|

| ||||||||||||||

ENERGIZED. |

|

|

| 400D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| JUMPER PLUG | |||||

|

|

|

|

|

|

|

| 400E |

|

|

| DC EXCITER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

2. ENGINE PROTECTION IS BYPASSED |

|

|

|

|

|

|

|

|

| + | 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BEHIND LOCAL / REMOTE SWITCH ON | |||||||

FOR ONE MINUTE TO ALLOW OIL |

|

|

|

|

|

| 15A |

| WINDING SPEC: | + |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RIGHT SIDEOF MACHINE(ASVIEWED | ||||||

PRESSURE BUILDUP. ENGINE MUST BE |

| 20A |

|

| CB2 |

| 40.5 - 42.5 OHMS AT 25C | 610A |

| 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| U |

| FROM CONTROL PANEL) |

| |||||||

STARTED WITHIN ONE MINUTE OF |

|

| CB1 |

|

|

| EXCITER REVOLVING |

| AC | AC DIODE |

|

|

|

|

|

|

|

|

|

|

|

|

|

| N | W | Y |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

TURNING IGNITION SWITCH ON OR THE |

|

| 11A |

|

| 7A |

| FIELD (ROTOR) | - |

| LOWER, RIGHT SIDEOF CONTROL PANEL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

FUEL SOLENOID, FUEL PUMP AND HOUR |

|

|

|

|

| 600C | - | 600B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

METER WILL TURN OFF. AFTER ONE |

| 400F 115 VOLT GFCI |

|

|

|

| SLIP RINGS | 21 | 600A |

|

|

|

|

|

|

| TOP, RIGHT PORTION |

|

|

|

|

|

|

|

| ||||||||||

MINUTE, THE IGNITION SWITCH MUST BE |

| 6A |

|

|

| POSITIVE SLIP RING | FUSE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

| RECEPTACLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

CYCLED OFF AND BACK ON TO START |

|

|

|

|

| IS NEAREST TO IRON | 15A |

| EXCITER CIRCUIT |

|

|

|

|

|

|

| OF CONTROL PANEL |

|

| N | U | W | Y |

|

| ||||||||||

|

|

|

|

| 810 |

|

|

| 215 |

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

ENGINE. |

|

|

| HOT LINE | HOT LOAD |

|

|

|

|

|

|

| LOWER, |

|

|

|

|

| CCW | RHEOSTAT |

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| LEAD 21A TO 21B |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

| RIGHT OF |

| WINDING SPEC: |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 602B |

|

|

|

|

|

| ||||||||

3. AFTER ENGINE STARTS, FLASHING |

| WHITE LINE | WHITE LOAD |

|

|

|

|

| 230 VOLT | CONTROL 214 | .488 OHMS MAX AT 25C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

CURRENT IS SUPPLIED TO THE ENGINE |

|

|

|

|

|

| 6A |

| RECEPTACLE | PANEL |

|

|

|

|

| 602A | 42 |

| 41 |

|

|

|

|

|

|

|

|

|

| ||||||

ALTERNATOR. |

|

|

| 820 |

|

|

|

|

|

|

|

| 810 |

|

| 115 VOLT CIRCUIT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| J8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

| 11C |

|

|

|

|

|

|

| LEAD 810 TO 820 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

4. AFTER ONE MINUTE, TIMER IS TIMED |

|

|

|

|

|

|

|

| EXCITER STATOR |

|

| 6 | 4 | 5 | 3 | 1 |

|

| 2 |

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| WINDING SPEC: |

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

OUT. IF OIL PRESSURE IS LOW, |

|

|

|

|

|

|

|

|

|

|

| 820 |

| (ALTERNATOR) | .230 OHMS MAX AT 25C |

| P9 |

|

|

|

|

|

|

| JUMPER PLUG IS |

|

|

|

|

|

| ||||

COOLANT TEMPERATURE IS HIGH OR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 41 |

| 600 |

|

|

|

|

|

| |||||||||

ALTERNATOR IS NOT CHARGING, THE |

|

|

|

|

|

|

| BEHIND CONTROL PANEL |

|

|

| 115 VOLT CIRCUIT |

|

| 602 | 42 | G |

|

|

|

|

|

|

| |||||||||||

ENGINE WILL SHUT DOWN AND THE |

|

|

|

|

|

|

|

|

| 11B | GENERATOR LEAD BLOCK | LEAD 820 TO 830 |

|

|

|

|

| LOCAL / REMOTE |

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

ENGINE PROTECTION LIGHT WILL COME |

|

|

|

|

|

|

|

|

|

| SHOWN AS VIEWED WITH | WINDING SPEC: |

|

|

|

|

|

|

|

| Y | SWITCH ON RIGHT |

|

|

|

|

|

| |||||||

ON. |

|

|

|

|

|

|

|

| 844A |

| TOP, LEFT PORTION | ENGINE IN THIS DIRECTION | .424 OHMS MAX AT 25C |

|

|

|

|

| X | W |

|

| SIDEOF MACHINE |

|

|

|

|

|

| ||||||

|

| IDLE SOLENOID CIRUIT LOGIC |

|

|

|

|

|

| OF CONTROL PANEL |

|

|

|

|

|

|

|

|

| REMOTE |

|

|

|

|

|

|

|

|

| MOUNTED TO NEGATIVE |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RECEPTACLE |

|

|

|

|

|

|

|

|

|

| |||

|

| 1. WHEN THE ENGINE IS RUNNING IN HIGH IDLE |

|

|

|

| SELECTOR SWITCH |

|

| SERIES FIELD |

|

|

| SHUNT |

|

|

|

| LOCAL / REMOTE |

|

|

|

| BRUSH HOLDER |

| ||||||||||

|

|

|

|

|

|

|

| - | + |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

|

| OR UNDER LOAD, THE SOLENOID IS NOT |

|

|

|

|

|

|

|

|

| FIELD |

|

|

|

|

|

|

| SWITCH |

|

|

|

|

| DIODE AND MOV ASSEMBLY | |||||||||

|

| ENERGIZED. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| 2. IF NO AUXILIARY CURRENT DRAW OR WELD |

|

|

|

|

|

|

|

| + | - |

|

|

|

|

|

|

|

| SHOWN IN LOCAL |

|

|

|

| THIS CIRCUIT USES THE |

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| POSITION |

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| COIL PAIR: |

|

|

|

|

|

|

|

|

|

| RESIDUAL MAGNETISM OF | |||||||||||

|

| LOAD IS SENSED FOR 15 SECONDS AND THE |

|

|

|

|

|

|

|

|

|

|

| 25.2 - 26.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| THE GENERATOR TO FLASH | ||||||

|

| IDLER SWITCH IS OPEN (AUTO), THE PULL AND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

| INTERPOLE |

|

| OHMS EACH |

|

|

|

|

|

|

|

|

|

|

|

|

| THE EXCITE THE ROTOR |

| ||||||||

|

| HOLD COIL OF THE IDLER SOLENOID ARE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

| COILS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WHICH IN TURN PROVIDES | |||||

|

| ENERGIZED. THE PULL COIL IS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| THE EXCITATION FOR THE | |||||

|

| AFTER HALF A SECOND. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GENERATOR |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

COMPONENT VALUE UNITS: | 3. IF AN AUXILIARY CURRENT DRAW OR WELD |

|

| BACKOF OUTPUT STUD |

|

|

|

|

|

|

| WELDING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

CAPACITOR: MFD/VOLTS | LOAD IS SENSED OR THE IDLER SWITCH IS CLOSED |

|

|

|

|

| BRUSH POSITION SHOWN AS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

| REED SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

RESISTOR: OHMS/WATTS | (HIGH), THE IDLE SOLENOID IS |

|

|

|

|

|

|

| VIEWED FROM CONTROL PANEL |

| GENERATOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

| SWITCH CLOSES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

| _ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

CONNECTOR PIN NUMBERS: |

|

|

|

|

|

| WITH FLOW OF |

| + |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| WELDING CURRENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

EX. 12 PIN CONNECTOR | LEAD COLOR CODE: | LABELS: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

1 2 | 6 |

|

|

|

|

| NEGATIVE OUTPUT | POSITIVE OUTPUT |

|

|

|

|

| THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED | |||||||||||||||||||||

|

|

|

| COMMON |

|

|

|

| TERMINAL | TERMINAL |

|

| PROPRIETARY & CONFIDENTIAL:TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC. |

| |||||||||||||||||||||

|

|

|

|

|

|

| TYPICAL OCV (WARM MACHINE): |

|

|

| MANUFACTURING TOLERANCE PER E2056 | CONTROL: CLEVELAND | SCALE: |

| EQUIPMENT TYPE: |

| CLASSIC 300D (PERKINS | PAGE 1 | OF 1 | ||||||||||||||||

|

| FRAME GROUND |

|

|

|

|

| UNLESS OTHERWISE SPECIFIED TOLERANCE: |

|

| |||||||||||||||||||||||||

7 | 12 |

|

|

| UNDER LEFT DOOR |

| ON 2 PLACE DECIMALS IS ± .02 in. (± 0.5 mm) | DRAWN BY: | C. Kocsis | NONE |

|

| |||||||||||||||||||||||

|

|

|

|

|

| ON 3 PLACE DECIMALS IS ± .002 in. (± 0.05 mm) | IF PRINTED |

| SUBJECT: |

|

| MACHINE SCHEMATIC |

| DOCUMENT | DOCUMENT | ||||||||||||||||||||

| LATCH |

| EARTH GROUND |

|

|

|

|

| ON ALL ANGLES IS ± .5 OF A DEGREE |

|

|

| @ A2 SIZE |

|

|

|

| NUMBER: | REVISION: | ||||||||||||||||

|

|

|

|

|

|

|

| MATERIAL TOLERANCE ("t") TO AGREE | ENGINEER: | D. BENDER |

|

|

|

| |||||||||||||||||||||

VIEW OF CONNECTOR ON PC BOARD |

|

|

|

|

|

|

|

|

|

|

|

| INCH |

| DISPOSITION: NA | DATE: |

| 1/11/2008 | NUMBER: | CRM37573 |

| L13096 | L13672 | A | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| DO NOT SCALE THIS DRAWING | APPROVED: | - |

|

|

| |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WITH PUBLISHED STANDARDS. |

|

|

| UNITS: |

| MATERIAL | APPROVAL |

|

| PROJECT |

|

| REFERENCE: |

|

| |||||

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

CLASSIC® 300D & 300G