Classic 300 D & 300 G

For Engine

Safety

Powered equipment

Electric Magnetic Fields

Can be dangerous

Electric Shock can kill ARC Rays can burn

Fumes and Gases

Classic 300D & 300G

For Electrically

Cylinder may explode

Iii

LES Machines À Souder À

Précautions DE Sûreté

Précautions DE Sûreté Pour

Transformateur ET À

Electromagnetic Compatibility EMC

L10093 3-1-96H

Master Table of Contents for ALL Sections

Table of Contents Installation Section

Welding Output Open Circuit Output Range Auxiliary Power

Installation

Technical Specifications Classic 300D

Height Width Depth Weight

Optional Features

Design Features

Rated Output Duty Cycle

PRE-OPERATION Installation

Diesel Fuel

PRE

Trailer

Vehicle Mounting

To prevent Explosion when

Battery Charging

Engine BREAK-IN

To prevent Electrical Damage when

Table of Contents Operation Section

See additional warning information at

Operation

Engine Operation

Cold Weather Starting

Welder Operation

See Specifications for

Do not Turn the Current Range Selec

Auxiliary Power

B1.4

Table of Contents Accessories Section

Maintenance section

Accessories

Optional Features

TIG Options

Magnum 250 Innershield Gun for LN-23P

Wire Feed Module K623-1 Provides constant volt

C1.3

Spool GUN Welder

C1.4 Classic 300D & 300G

Table of Contents Maintenance Section

Maintenance

Maintenance

Engine

Idler Maintenance

Purging Air from Fuel System Perkins

Nameplates

D1.4

For Codes 10658 and below

D1.5

For Codes 10911 and Above

Resetting Procedure

D1.6

Figure D1.7 Major Component Location

D1.7

D1.8 Classic 300D & 300G

A2.1

Description Rated DC Output

Model Height Width Depth Weight

DC Current Range Volts @ Rated Amps Cycle

Engine

When starting and stopping welding or using auxil

A2.3

Muffler

Lift Bail

Machine Grounding

Exhaust Spark Arrester

Do not Mount Over Combustible SU

Fuel Polarity Control and Cable Sizes

PRE-OPERATION Service

OIL

Cooling System

Battery Acid can burn eyes Skin

Battery Charging

A2.6 Gases from Battery can explode

A2.6

B2.1

Stopping the Engine

Maintenance sec

High Altitude Operation

Starting the Classic 300D Perkins

Contacts and damage the switch

B2.3

Idler Operation Auxiliary Power

B2.4

C2.1

TIG Options General Options

Stick Options Accessory SET K704

Trailer K953-1

Wire Feed Module K623-1 Magnum Spool Gun K487-25

Wire Feeder Options

C2.3

C2.4 Classic 300D & 300G

D2.1

Safety Precautions

Information at

Perkins 404C-22 Engine

Idler Maintenance

Purging AIR from Fuel System

Nameplates

Tension of alternator drive belt

Service Decal for Codes 11249 and below

D2.4

All nuts and bolts for tightness

Service Decal for Codes 11250 and Above

MAINTENANCED2.5

D2.5

D2.6MAINTENANCED2.6

Gfci Receptacle Testing and Reset Ting Procedure

Case Front Assembly

D2.7

D2.8 Classic 300D & 300G

A3.1

Technical Specifications Classic 300D Kubota

A3.2

Control Panel High Idle RPM OCV Adjustment

A3.3

Not Mount Over Combustible Surfaces

This operatorʼs manual

Angle of Operation

Falling

Polarity Control and Cable Sizes Fuel

GAS ES from Battery can explode

Battery Charging Warning

A3.6

B3.1

Starting the Classic 300D Kubota V2203M

Diesel Engine

B3.3

Control of Welding Current

B3.4

Idler Operation

C3.1

TIG Options

Stick Options

Wire Feed Options

C3.3

C3.4 Classic 300D & 300G

D3.1

D3.2

Air Bleeding

Kubota V2203M Engine

D3.3

Valve

Engine Service

D3.4

D3.5MAINTENANCED3.5

Figure D3.6 Major Component Location

D3.6

A4.1

A4.2

General Description

A4.3

See Optional Features

A4.4

Instructions supplied with this machine

Read the engine operating and maintenance

A4.5

Can

A4.6

B4.1

B4.2

404D-22 Diesel Engine

Selector setting and lower open circuit voltage

B4.3

B4.4

C4.1

C4.2

Power Plug Kit K802D

Service Indicator Kit K1858-1 Water Valve Kit K844-1

Ball Hitch K958-1 K958-2 Control Cable Extension K937-45

Magnum Spool Gun K487-25 Wire Feed Module K623-1

C4.3

C4.4 Classic 300D & 300G

D4.1

D4.2

Perkins 404D-22 Engine

D4.3

MAINTENANCED4.4

D4.4

D4.5MAINTENANCED4.5

Figure D4.6 Major Component Location

D4.6

A5.1

A5.2

Technical Specifications Classic 300G K1754-1

Description Rated DC Output Duty Cycle DC Current Range

Exhaust Spark Arrester Lift Bail

Do not Mount Over Combustible SUR

Gasoline

Vehicle Mounting

A5.5

A5.6 Classic 300D & 300G

B5.1

B5.2

Design Features

Starting and stopping welding or using auxiliary

Do not Mount Over Combustible Surfaces

Refer to the Engine

High Idle RPM OCV Adjustment- a potentiometer is

B5.3

Starting the Classic 300G GM 3.0L

Throttle Body Deicing System

B5.4

Idler Control Operation

C5.1

Optional Equipment

C5.2

D5.1

Commutator and Brushes

Bearings

General Instructions

Purging AIR from Fuel System GM

Idler Control Maintenance

Engine Maintenance

0L Engine

Engine Service

D5.4

Figure D5.5 Major Component Location

D5.5

D5.6 Classic 300D & 300G

1TABLE of CONTENTS-THEORY of Operation Section E-1

Theory of Operation

Gasoline Engine

Perkins

BATTERY, STARTER, Engine Alternator & Protection Circuits

Classic 300G, Zenith Fuel System/GM Engine

Classic 300D, Perkins Engine

Classic 300D, Kubota Engine

TOR and Rotor

Fine Current Adjustment

Adjustment Coils

Excitation Flashing

Figure E.8 Classic 300D, Perkins Engine

11472,

Engine Idler Circuit

11135 10657, 10658, 10911,

Theory of Operation

DC Generator Machines

Classic 300D & 300G

Troubleshooting and Repair

Table of Contents

Recommended

HOW to USE Troubleshooting Guide

Locate Problem Symptom

Perform External Tests

PC Board Troubleshooting Procedures

Electric Shock

Perform the Brush and Slip

Adjustment Test

Ring Service Procedure

Perform the Flash Voltage

Commutator Inspection

Service Procedure

Generator Brush

Shunt Field Coil

Output takes a long time to

Weld output is considerably

Adjustment Procedure if

Rocker Adjustment

Perform the Shunt Field Coil

Procedure

RPM Adjustment Test

Slip Ring Service

Exciter Rotor Resistance and Ground Test Shunt Field Coil

Welding

Brush and Slip

Flash Voltage

Engine will not crank when

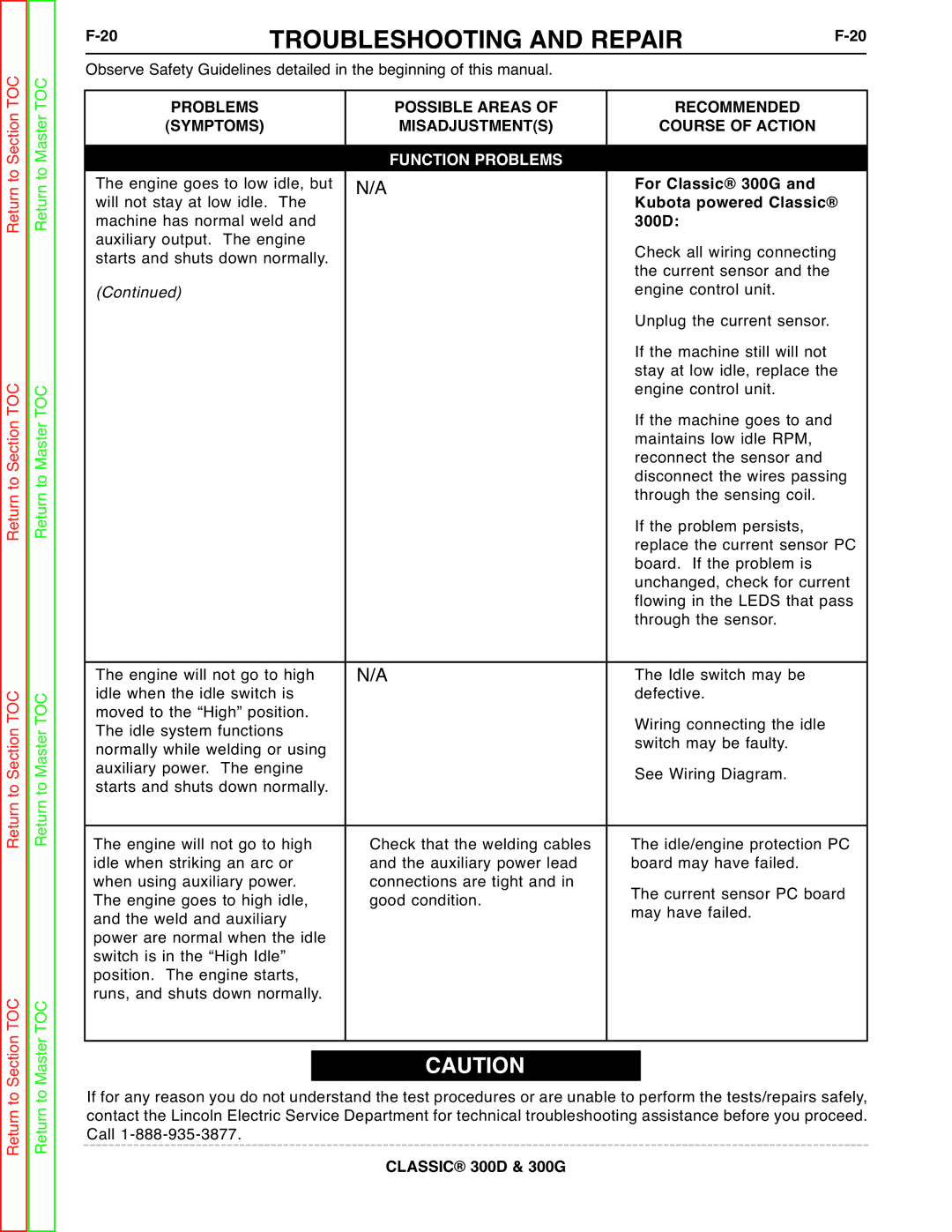

Function Problems

System Voltage Tests

Verify that the engine control

Protection System Test

Perform the Engine Alternator

Machine will not idle down

Kubota powered units

For Classic 300G

Engine goes to low idle, but

Kubota powered Classic

Perkins powered models

Classic 300G Classic 300D Kubota Powered machines

Troubleshooting and Repair

Exciter/Auxiliary Power Alternator

23TROUBLESHOOTING and REPAIRF-23

Brush & Slip Ring Service Procedure

Procedure Description

Cleaning the Slip Rings

24TROUBLESHOOTING and REPAIRF-24

Procedure

Seating Brushes

Engine Alternator Test Procedure

25TROUBLESHOOTING and REPAIRF-25

Test Description

Engine Alternator Test Procedure

27TROUBLESHOOTING and REPAIRF-27

Engine Fuel System Voltage Test Procedure

Engine Fuel System Voltage Test Procedure

29TROUBLESHOOTING and REPAIRF-29

Engine Protection System Test Procedure

TED to RUN White Overheated or with

Engine Protection System Test Procedure

Warranty will not Cover the Damage

TOW OIL PRESSURE, Severe Engine DAM

Engine RPM Adjustment Test Procedure

31TROUBLESHOOTING and REPAIRF-31

Materials Needed Miscellaneous hand tools Strobe tachometer

Classic 300D Perkins only

Engine RPM Adjustment Test Procedure

Engine RPM Adjustment Procedure later in this section

Strobe-Tach Method

Low idle adjustment

Classic 300D & 300G

35TROUBLESHOOTING and REPAIRF-35

Flashing Voltage Test Procedure

Flashing Voltage Test Procedure

Rocker Adjustment Procedure

Initial rocker placement

38TROUBLESHOOTING and REPAIRF-38

Rocker Adjustment Procedure

Tighten

Check for Max output

Classic 300D & 300G

Exciter Rotor Resistance and Ground Tests Procedure

41TROUBLESHOOTING and REPAIRF-41

Exciter / Auxiliary Power Alternator

Static Tests

42TROUBLESHOOTING and REPAIRF-42

Dynamic Tests

43TROUBLESHOOTING and REPAIRF-43

Classic 300D & 300G

45TROUBLESHOOTING and REPAIRF-45

Shunt Field Coil Resistance and Ground Test Procedure

Test the shunt coil resistance

Shunt Field Coil Resistance and Ground Test

Shunt coil ground test

Shunt Field Coil Resistance and Ground

47TROUBLESHOOTING and REPAIRF-47

Shunt Field Circuit Voltage Test Procedure

Shunt Field Circuit Voltage Test Procedure

49TROUBLESHOOTING and REPAIRF-49

Exciter Stator Short Circuit & Ground Test Procedure

Exciter Stator Short Circuit & Ground Test Procedure

Weld Circuit Ground and Short Circuit Test Procedure

Weld circuit ground test

If the resistance is lower than 500k Ohms

53TROUBLESHOOTING and REPAIRF-53

Welding Generator Brush and Commutator

54TROUBLESHOOTING and REPAIRF-54

Inspection and Service Procedure

Perform the Weld Circuit Ground and Short Circuit Test

Uneven Commutator appearance

55TROUBLESHOOTING and REPAIRF-55

Pitted and Are Damaged Commutator

Examine the brushes

Classic 300D & 300G

57TROUBLESHOOTING and REPAIRF-57

Series Coil Short Circuit Test Procedure

Series Coil Short Circuit Test Procedure

16.6 ms

Scope Settings

High Idle no Load Fine Current Control Rheostat AT Maximum

CH1

60TROUBLESHOOTING and REPAIRF-60

Normal Open Circuit DC Weld Voltage Waveform

Machine Loaded Selector Switch AT Maximum Position

61TROUBLESHOOTING and REPAIRF-61

Typical DC Weld Output Voltage Waveform

Classic 300D & 300G

Description

63TROUBLESHOOTING and REPAIRF-63

Alternator Rotor Removal Replacement Procedure

Materials Needed 3/8 wrench

Replacement Procedure

64TROUBLESHOOTING and REPAIRF-64

Alternator Rotor Removal

Troubleshooting and Repair

66TROUBLESHOOTING and REPAIRF-66

Figure F.6 Rotor Removal

Replacement Procedure

Replacement

Classic 300D & 300G

Alternator Stator Removal and Replacement Procedure

69TROUBLESHOOTING and REPAIRF-69

Materials Needed 3/8 nut driver

Procedure

70TROUBLESHOOTING and REPAIRF-70

Alternator Stator Removal and Replacement

Perform the Alternator Rotor Removal

71TROUBLESHOOTING and REPAIRF-71

Figure F.8 Lead Disconnection Points

Replacement

Genernator Brush HOLDER/COIL Cables

73TROUBLESHOOTING and REPAIRF-73

Rotor Removal and Replacement pro

Classic 300D & 300G

75TROUBLESHOOTING and REPAIRF-75

Generator Frame Removal and Replacement Procedure

Generator Frame

76TROUBLESHOOTING and REPAIRF-76

Removal and Replacement

Perform the Alternator Stator Removal

Removal and Replacement

78TROUBLESHOOTING and REPAIRF-78

See Figure F.14 for steps 14

79TROUBLESHOOTING and REPAIRF-79

Rope Sling

80TROUBLESHOOTING and REPAIRF-80

81TROUBLESHOOTING and REPAIRF-81

Generator Armature Removal and Replacement Procedure

Removal and Replacement Procedure

82TROUBLESHOOTING and REPAIRF-82

Generator Armature

Current Rheostat at Maximum

AC Auxiliary Power Receptacle Output

RPM

Classic 300D & 300G

Table of Contents Diagram Section

Electrical Diagrams

Wiring Diagram Codes 10545, 10546, 10657, 10658 L10877

Classic 300G Wiring Diagram

Classic 300D Wiring Diagram

Wiring Diagram Codes 10911, 10927 L11865

Classic 300G Wiring Diagram

Wiring Diagram Codes 10912, 11135 L11866

Classic 300D Perkins Wiring Diagram

Wiring Diagram Codes 11110, 11111 M20499

Classic 300D Kubota Wiring Diagram

Wiring Diagram Codes 11112, 11113 M20432

Wiring Diagram Codes 11243, 11244 M20432-1

OU Tput Terminals

Wiring Diagram Codes 11248, 11249, 11280, 11281 M20616

Wiring Diagram Codes 11411, 11412 M21292

Wiring Diagram Codes 11413, 11414 M21293

Wiring Diagram Codes 11472, 11473 M21684

Wiring Diagram Codes 11474, 11475 M21563

To Iron

Schematic Complete Machine Codes 11110, 11111 L12412

L12412

Schematic Complete Machine Codes 11112, 11113 L12265

L12265

Schematic Complete Machine Codes 11243, 11244 L12265-1

L12265-1

L12561

Lower Left Machine

Schematic Complete Machine Codes 11411, 11412 L13096

L13096

Schematic Complete Machine Codes 11413, 11414 L13097

L13097

Schematic Complete Machine Codes 11472, 11473 L13672

L13672

Schematic Complete Machine Codes 11474, 11475 L13351

L13351

Wire Feed Module Wiring Diagram

Wiring Diagram Wire Feed Module Option L9259

Schematic Wire Feed Module Option G2562

Classic 300D & 300G

Electrical Diagrams

Schematic Current Sensor PC BD Kubota Engine only S25973