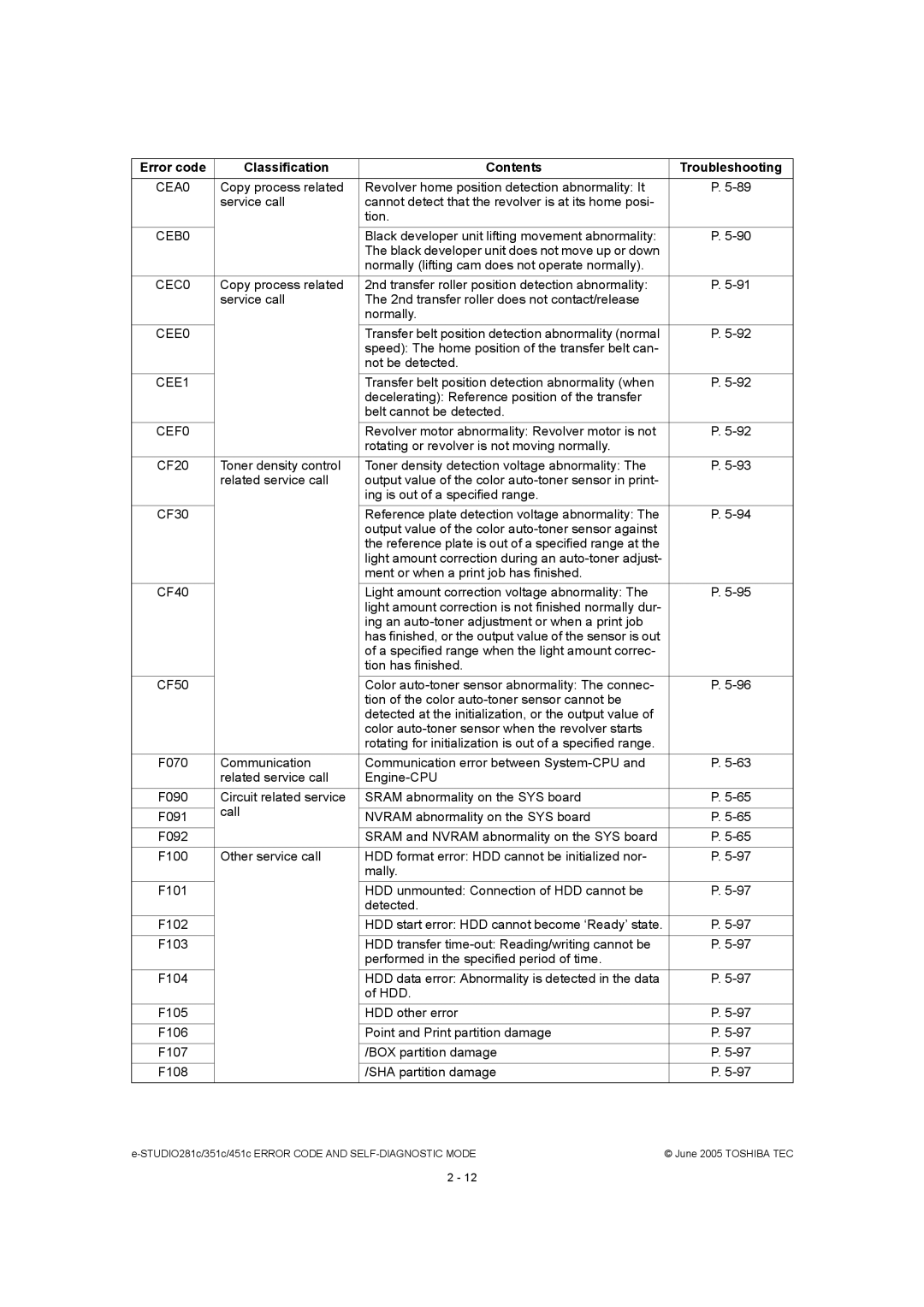

Error code | Classification | Contents | Troubleshooting | |

CEA0 | Copy process related | Revolver home position detection abnormality: It | P. | |

| service call | cannot detect that the revolver is at its home posi- |

| |

|

| tion. |

| |

CEB0 |

| Black developer unit lifting movement abnormality: | P. | |

|

| The black developer unit does not move up or down |

| |

|

| normally (lifting cam does not operate normally). |

| |

CEC0 | Copy process related | 2nd transfer roller position detection abnormality: | P. | |

| service call | The 2nd transfer roller does not contact/release |

| |

|

| normally. |

| |

CEE0 |

| Transfer belt position detection abnormality (normal | P. | |

|

| speed): The home position of the transfer belt can- |

| |

|

| not be detected. |

| |

CEE1 |

| Transfer belt position detection abnormality (when | P. | |

|

| decelerating): Reference position of the transfer |

| |

|

| belt cannot be detected. |

| |

CEF0 |

| Revolver motor abnormality: Revolver motor is not | P. | |

|

| rotating or revolver is not moving normally. |

| |

CF20 | Toner density control | Toner density detection voltage abnormality: The | P. | |

| related service call | output value of the color |

| |

|

| ing is out of a specified range. |

| |

CF30 |

| Reference plate detection voltage abnormality: The | P. | |

|

| output value of the color |

| |

|

| the reference plate is out of a specified range at the |

| |

|

| light amount correction during an |

| |

|

| ment or when a print job has finished. |

| |

CF40 |

| Light amount correction voltage abnormality: The | P. | |

|

| light amount correction is not finished normally dur- |

| |

|

| ing an |

| |

|

| has finished, or the output value of the sensor is out |

| |

|

| of a specified range when the light amount correc- |

| |

|

| tion has finished. |

| |

CF50 |

| Color | P. | |

|

| tion of the color |

| |

|

| detected at the initialization, or the output value of |

| |

|

| color |

| |

|

| rotating for initialization is out of a specified range. |

| |

F070 | Communication | Communication error between | P. | |

| related service call |

| ||

F090 | Circuit related service | SRAM abnormality on the SYS board | P. | |

| call |

|

| |

F091 | NVRAM abnormality on the SYS board | P. | ||

| ||||

F092 |

| SRAM and NVRAM abnormality on the SYS board | P. | |

F100 | Other service call | HDD format error: HDD cannot be initialized nor- | P. | |

|

| mally. |

| |

F101 |

| HDD unmounted: Connection of HDD cannot be | P. | |

|

| detected. |

| |

F102 |

| HDD start error: HDD cannot become Ready state. | P. | |

F103 |

| HDD transfer | P. | |

|

| performed in the specified period of time. |

| |

F104 |

| HDD data error: Abnormality is detected in the data | P. | |

|

| of HDD. |

| |

F105 |

| HDD other error | P. | |

F106 |

| Point and Print partition damage | P. | |

F107 |

| /BOX partition damage | P. | |

F108 |

| /SHA partition damage | P. |

| © June 2005 TOSHIBA TEC |

2 - 12