Notes:

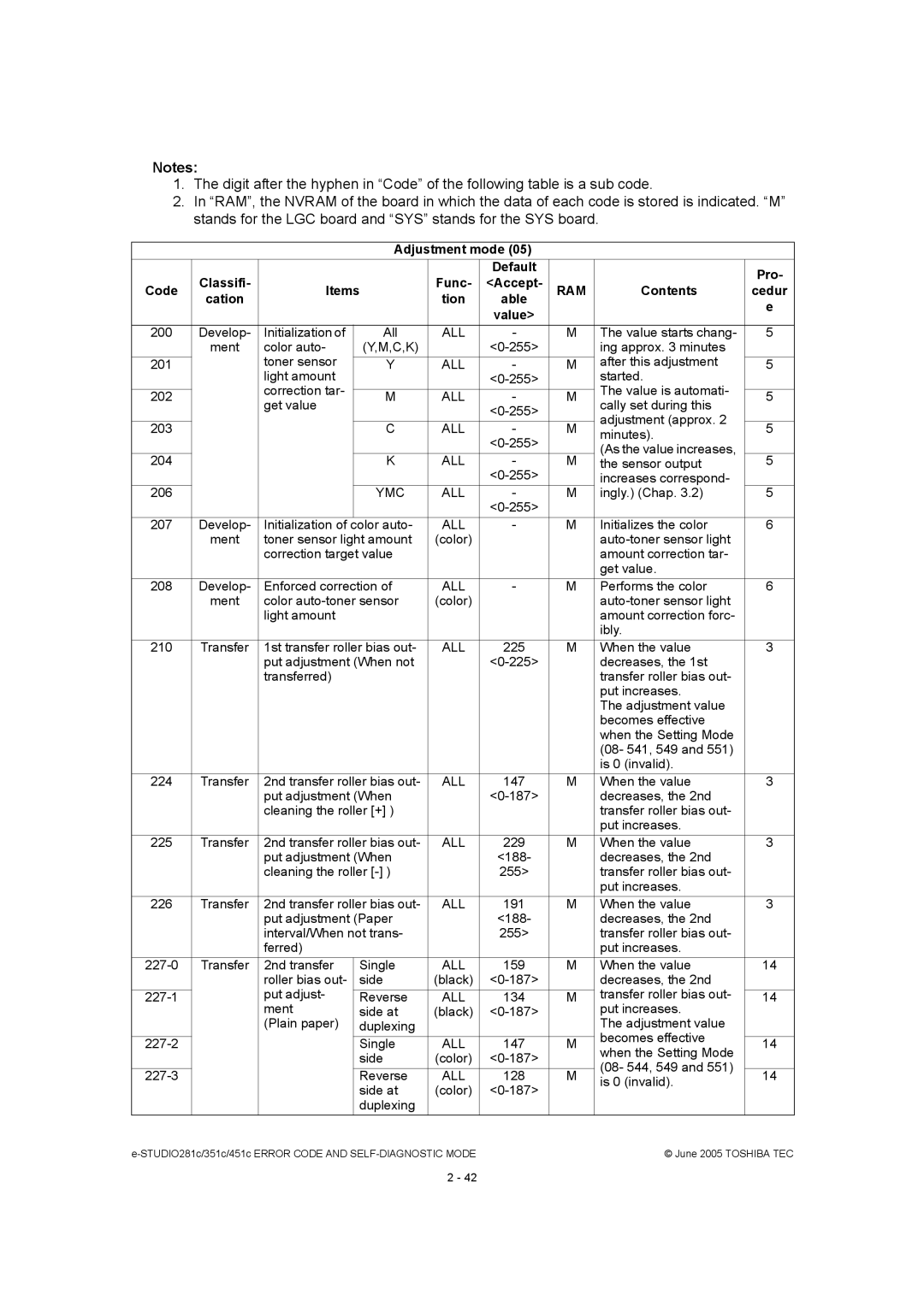

1.The digit after the hyphen in Code of the following table is a sub code.

2.In RAM, the NVRAM of the board in which the data of each code is stored is indicated. M stands for the LGC board and SYS stands for the SYS board.

|

|

|

| Adjustment mode (05) |

|

|

| ||

|

|

|

|

|

| Default |

|

| Pro- |

| Classifi- |

|

|

| Func- | <Accept- |

|

| |

Code | Items | RAM | Contents | cedur | |||||

| cation |

|

|

| tion | able |

|

| e |

|

|

|

|

|

| value> |

|

| |

|

|

|

|

|

|

|

|

| |

200 | Develop- | Initialization of | All | ALL | - | M | The value starts chang- | 5 | |

| ment | color auto- | (Y,M,C,K) |

|

| ing approx. 3 minutes |

| ||

|

| toner sensor |

|

|

|

|

| after this adjustment |

|

201 |

|

| Y | ALL | - | M | 5 | ||

|

| light amount |

|

|

| started. |

| ||

|

| correction tar- |

|

|

|

|

| The value is automati- |

|

202 |

|

| M | ALL | - | M | 5 | ||

| get value | cally set during this | |||||||

|

|

|

|

|

| ||||

|

|

|

|

|

|

| adjustment (approx. 2 |

| |

203 |

|

|

| C | ALL | - | M | 5 | |

|

|

| minutes). | ||||||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| (As the value increases, |

| |

204 |

|

|

| K | ALL | - | M | the sensor output | 5 |

|

|

|

|

|

|

| increases correspond- |

| |

206 |

|

|

| YMC | ALL | - | M | ingly.) (Chap. 3.2) | 5 |

|

|

|

|

|

|

|

|

| |

207 | Develop- | Initialization of | color auto- | ALL | - | M | Initializes the color | 6 | |

| ment | toner sensor light amount | (color) |

|

|

| |||

|

| correction target value |

|

|

| amount correction tar- |

| ||

|

|

|

|

|

|

|

| get value. |

|

208 | Develop- | Enforced correction of | ALL | - | M | Performs the color | 6 | ||

| ment | color | (color) |

|

|

| |||

|

| light amount |

|

|

|

| amount correction forc- |

| |

|

|

|

|

|

|

|

| ibly. |

|

210 | Transfer | 1st transfer roller bias out- | ALL | 225 | M | When the value | 3 | ||

|

| put adjustment (When not |

|

| decreases, the 1st |

| |||

|

| transferred) |

|

|

|

| transfer roller bias out- |

| |

|

|

|

|

|

|

|

| put increases. |

|

|

|

|

|

|

|

|

| The adjustment value |

|

|

|

|

|

|

|

|

| becomes effective |

|

|

|

|

|

|

|

|

| when the Setting Mode |

|

|

|

|

|

|

|

|

| (08- 541, 549 and 551) |

|

|

|

|

|

|

|

|

| is 0 (invalid). |

|

224 | Transfer | 2nd transfer roller bias out- | ALL | 147 | M | When the value | 3 | ||

|

| put adjustment (When |

|

| decreases, the 2nd |

| |||

|

| cleaning the roller [+] ) |

|

|

| transfer roller bias out- |

| ||

|

|

|

|

|

|

|

| put increases. |

|

225 | Transfer | 2nd transfer roller bias out- | ALL | 229 | M | When the value | 3 | ||

|

| put adjustment (When |

| <188- |

| decreases, the 2nd |

| ||

|

| cleaning the roller |

| 255> |

| transfer roller bias out- |

| ||

|

|

|

|

|

|

|

| put increases. |

|

226 | Transfer | 2nd transfer roller bias out- | ALL | 191 | M | When the value | 3 | ||

|

| put adjustment (Paper |

| <188- |

| decreases, the 2nd |

| ||

|

| interval/When not trans- |

| 255> |

| transfer roller bias out- |

| ||

|

| ferred) |

|

|

|

| put increases. |

| |

Transfer | 2nd transfer | Single | ALL | 159 | M | When the value | 14 | ||

|

| roller bias out- | side | (black) |

| decreases, the 2nd |

| ||

|

| put adjust- |

|

|

|

|

| transfer roller bias out- |

|

|

| Reverse | ALL | 134 | M | 14 | |||

|

| ment | side at | (black) |

| put increases. |

| ||

|

| (Plain paper) | duplexing |

|

|

| The adjustment value |

| |

|

|

|

|

|

|

|

| becomes effective |

|

|

|

| Single | ALL | 147 | M | 14 | ||

|

|

| when the Setting Mode | ||||||

|

|

|

| side | (color) |

|

| ||

|

|

|

|

| (08- 544, 549 and 551) |

| |||

|

|

| Reverse | ALL | 128 | M | 14 | ||

|

|

| is 0 (invalid). | ||||||

|

|

|

| side at | (color) |

|

| ||

|

|

|

|

|

|

| |||

|

|

|

| duplexing |

|

|

|

|

|

|

| © June 2005 TOSHIBA TEC | |||||||

2 - 42