WJ200 Series Inverter Quick Reference Guide

Page

UL→ Cautions, Warnings and Instructions

Marking Requirements

Terminal symbols and Screw size

Fuse Sizes

5AT 123 45A-001 1005

Inverter Specification Label

Model-specific tables for 200V and 400V class inverters

WJ200 Inverter Specifications

WJ200 Inverter Specifications, …

WJ200 inverters, 400V models

Derating

GFI

Basic System Description

Inverter +

Motor Output

Determining Wire and Fuse Sizes

Allowable current

T1 V/T2 W/T3 L1 S/L2 T/L3 U/T1 V/T2 W/T3

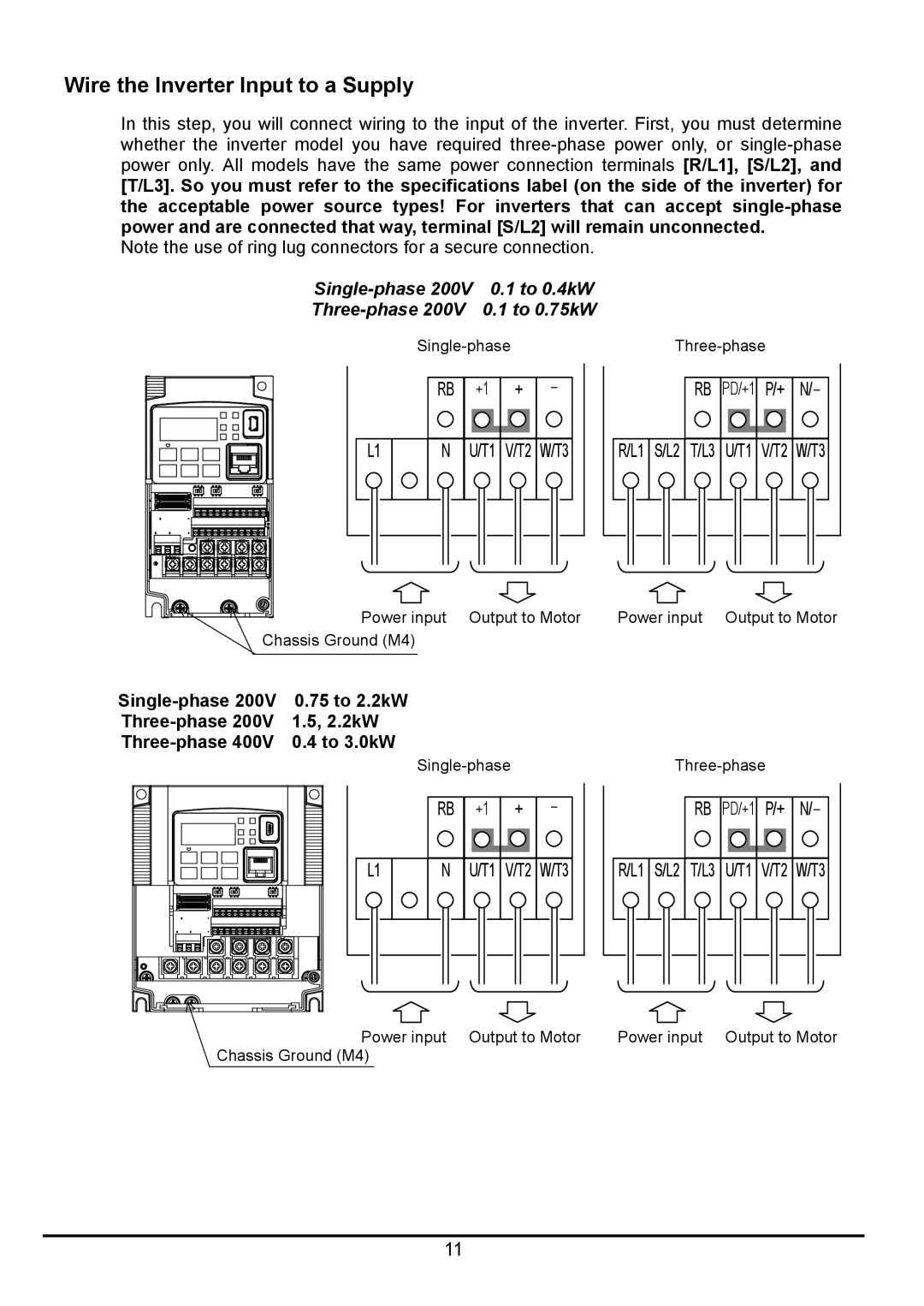

Wire the Inverter Input to a Supply

RB PD/+1 P/+

Three-phase 200V 11kW Three-phase 400V 11, 15kW

Key and Indicator Legend

Using the Front Panel Keypad

Power LED Alarm LED

Keypad Navigation Map

Keys, Modes, and Parameters

PRG LED

Group F

Group d

Save

Group a

F001

Key

GND

Connecting to PLCs and Other Devices

Motor

Example Wiring Diagram

Pulse

Control Logic Signal Specifications

Train

Output Input

SP, SN

Wiring sample of control logic terminal sink logic

Sink/source logic of intelligent input terminals

Wire size for control and relay terminals

Recommended ferrule

Intelligent Inputs

Intelligent Terminal Listing

Intelligent Outputs

Sink logic connection

Using Intelligent Input Terminals

Source logic connection

WJ200

Sinking Inputs, Internal Supply

Sourcing Inputs, Internal Supply

Sourcing Inputs, External Supply

Sinking Inputs, External Supply

OFF

Inserting

Option Terminal Code Symbol Function Name State Description

Forward Run/Stop and Reverse Run/Stop Commands

Multi-Speed Select ~Binary Operation

Required settings

FW,RV

Two Stage Acceleration and Deceleration

2CH

Unattended Start Protection

Option Terminal Function Name State Description Code Symbol

USP

Reset Inverter

Run Signal

Using Intelligent Output Terminals

Code Symbol

Option Terminal Function Name

Settings

Frequency Arrival Signals

Required

FA3/FA5

FA2/FA4

Stop

Alarm Signal

Trip

During normal operation

AM H O OI L

Analog Input Operation

AM H O OI

Other Analog Input-related topics

SN 7 6 5 4 3 2 1 L PLC P24

Pulse Train Input Operation

Analog Output Operation

AM signal offset and gain are adjustable, as indicated below

Monitoring functions

D007

D006

D008

D009

D030

D029

D050

D060

Main Profile Parameters

Standard Functions

A220

A015

A241

A021 ~ A035

A043

A242

A243

A044

A059

A058

A061

A261

A073

A072

A074

A075

A292

A092

A093

A293

A132

A131

A141

A142

A157

A156

A161

A162

Fine Tuning Functions

B212

B012

B013

B213

B026

B025

B027

B028

B038

B037

B039

B040

B061

B060

B062

B063

B088

B087

B089

B090

B097

B096

B100

B101

B134

B133

B145

B150

Intelligent Terminal Functions

C030

C028

C031

C032

C052

C047

C053

C054

C077

C076

C078

C081

C103

C102

C104

C105

C148

C147

C149

C150

FWD, REV

Anlg

Pidc

DWN

SF2

SF1

SF3

SF4

255

Run Signal When the inverter is in Run Mode

LOG2

LOG1

LOG3

MO1

C039

MO2

MO3

Motor Constants Functions

PM Motor Constants Functions

H113

H112

H116

H117

Expansion Card Functions

P044

P041

P045

P046

P073

P072

P075

P077

Trip History and Inverter Status

Monitoring Trip Events, History, & Conditions

Error Name Causes Code

Error Codes

E37

Error Name Descriptions Code

Restoring Factory Default Settings

Other indication

Important notes

CE-EMC Installation Guidelines

Page

Page

Metal plate earth

Installation for WJ200 series example of SF models

Hitachi EMC Recommendations

Introduction

Functional Safety Certification in Progress

Stop Category defined in EN60204-1

How it works

Installation

Wiring example

OFF

G9SX

GS9A

NE1A