Simatic

Related catalogs

Simatic PCS

Siemens Automation and Drives. Welcome

Siemens AG Siemens ST PCS 7 · November

Sharpen your competitive edge. Totally Integrated Automation

Simatic IT

Products and systems

Main Message Selective Protocols Tenance Error Protection

Siemens AG

Siemens AG Siemens ST PCS 7 · November

System architecture

Overview

Totally Integrated Automation with Simatic PCS

Benefits

Function

Consistent and homogeneous overall system

Flexibility and scalability

Introduction

System-neutral components

System documentation

Teleperm M Manual Collection

S5 Manual Collection

Selection and Ordering Data

More information

Simatic S7 manuals

Simatic S5 manuals

Administration

Simatic Logon Upgrade

Simatic Logon Admin Tool

Simatic Logon Service

Access security by means of chipcard reader

Options

Only for TIA applications

Options

Operating system upgrade

Operating system

Introduction

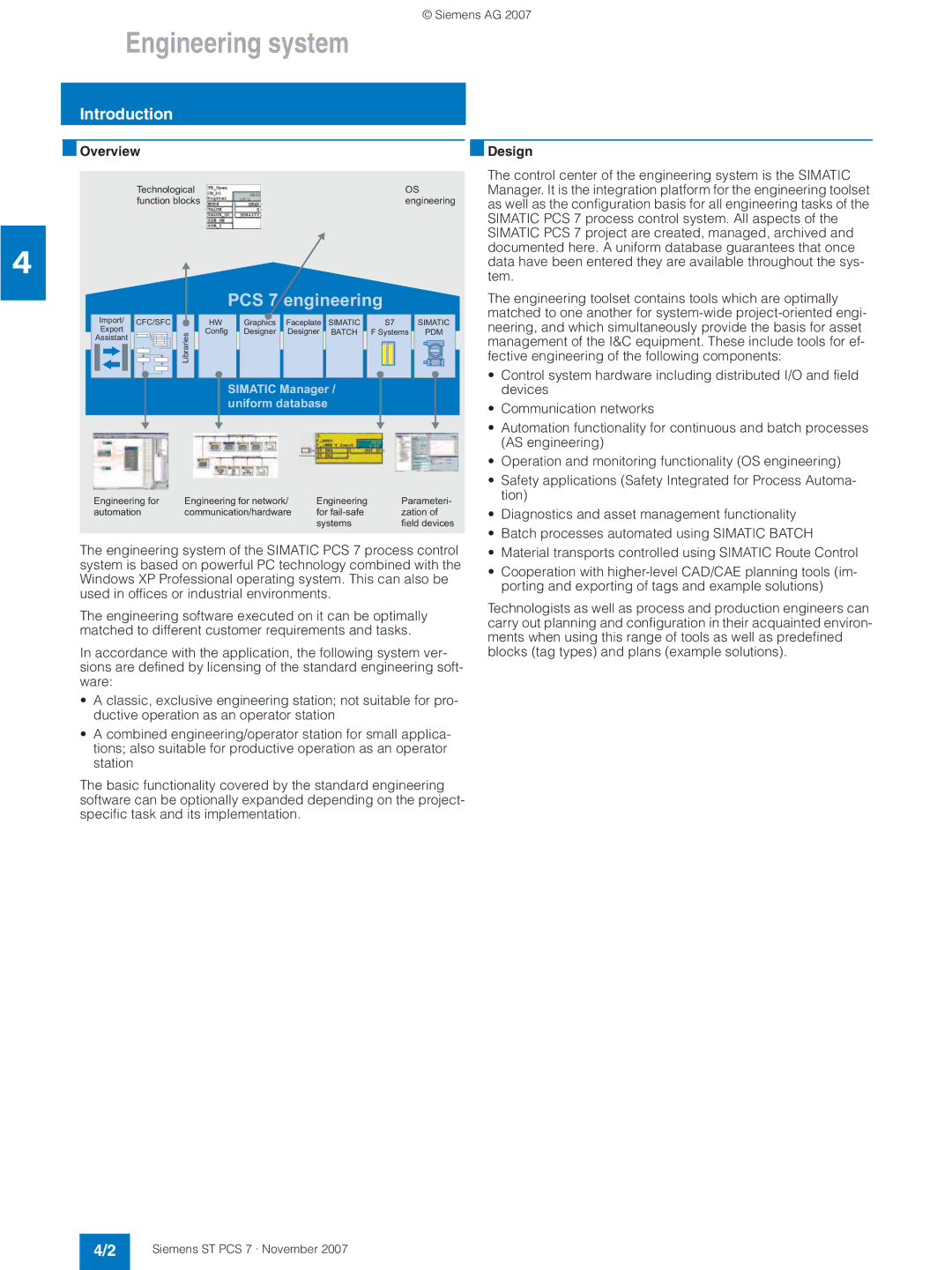

Overview Design

Microsoft Windows operating system

Monitors and multi-VGA operation

Specifications

Simatic PCS 7 Industrial Workstation

Technical

Basic hardware

Simatic PCS 7 Industrial Workstation

CPU

Basic hardware

Overview Application

Restore DVD

Technical specifications

CPU

Operating systems and diagnostics software

Monitoring/diagnostics functions

Safety

Noise level

Power supply

Dimensions and weights

Selection and Ordering Data Order No

Simatic PCS 7 Industrial Workstation, server version

Accessories

Power supply cable for Rack PC

Keyboards

Tower Kit

Overview Technical specifications

Multi-VGA graphics cards

Multi-VGA graphics cards

Multi-VGA Graphics Card

Operator panels/monitors

Operating devices

Process monitors

Special configurations

Configurator in the A&D Mall

Starter systems

Runtime Basic Packages

Use as asset management station

Simatic PCS

Profibus DP/PA

Simatic PCS 7 BOX RTX

EMC

Technical specifications Cont

Automation WinAC software PLC

All-in-one system

Runtime system

Simatic PCS 7 BOX RTX

Simatic PDM

Simatic PDM PCS 7

Simatic PCS 7 BOX

Operating system Diagnostics software

WinAC Slot 416

Use with Simatic Batch

Use with Simatic Route Control

Mechanical environmental Conditions

Automation WinAC Slot PLC module

Profibus DP

Simatic PCS 7 BOX 416 all-in

Simatic PCS 7 BOX

Simatic PCS 7 PowerPacks Licenses for runtime System

Power supply 230 V AC

6EP1 334-2AA01

6EP1 931-2EC31

Runtime Basic Packages

Simatic PCS 7 Runtime Basic

Package AS

Order No

Engineering Process Safety

Introduction

ES hardware

ES software

Engineering system

Technical specifications4

ES hardware

ES single station

Options/expansions

ES software

Yes

Productive operation

Standard engineering software

Simatic Logon

Simatic Manager

Component view HW-Config

Process object view

Continuous function chart CFC

Sequential function chart SFC

Libraries

PID Tuner

Simatic PCS 7 Engineering PowerPack AS/OS

Graphics designer and faceplate designer

Simatic PCS 7 Engineering Software

Simatic PCS 7 Engineering Software V7.0 Rental License

Upgrade

Version Cross Manager

Overview Selection and Ordering Data Order No

Data exchange with planning tools

Simatic Version Trail Upgrade 6ES7 658-1FX07-2YE5 V7.0

Version Trail

Simatic Version Trail 6ES7 658-1FX07-2YA5

Import/Export Assistant

Overview Benefits

Efficient processing of mass data

Simatic PCS 7 Import/Export 6ES7 658-1DX07-2YB5 Assistant

Simatic PDM Process Device Manager

Profibus DP fieldbus

Minimum configuration Simatic PDM Single Point

Customer-oriented product structure

Simatic PDM S7

PCS

Predefined product configurations

Components for individual configuration

TAG options/PowerPacks

Demonstration software

Core functions

Support of system management

Graphical user interface

Communication

Integration

Device Integration

Contact addresses

Support Request

Simatic PDM Upgrade/Update Service

Minimum configuration Simatic PDM Single Point

Components for individual configuration

Selection and ordering data for TIA applications

TAG options / PowerPacks

Simatic PCS

Engineering Process Safety

Benefits

Configuration

S7 F ConfigurationPack

S7 F Systems Upgrade from 6ES7 833-1CC01-0YE5 V5.x to

Engineering F/FH systems

Simatic Safety Matrix

Simatic Safety Matrix Editor

System requirements

Hardware Software Requirement

Simatic Safety Matrix Tool

Simatic Safety Matrix Editor

Simatic PCS 7 Safety ES Packages

S7-PLCSIM Software Update

Simulation

Simulation with S7-PLCSIM

S7-PLCSIM

OS hardware

OS software

Redundant operator systems

OS archiving

Operator system

Definitions

Process objects OS variables approx

OS quantity framework

Long-term archiving

OS hardware

Single-user system OS single station

Multi-user system with client/server architecture

OS archiving

OS basic hardware

OS single station

OS server

Simatic PCS 7 Industrial Workstation, server version

Upgrade from BCE to CP 1613 communication

CP 1613 A2 6GK1 161-3AA01

Simatic NET S7-1613/2006 for

Industrial Ethernet

Signal output

Overview Signal module

Order No PCI Signal Module 6DS1 916-8RR

OS software

Simatic PCS 7 ES/OS 547B IE WXP

With Windows 2003 Server operating system

Trends Messages and alarms

Sign-of-life monitoring

Clock synchronization

Script languages

OS standard software For single station/server/client

OS Software Single Station

OS Software Server OS Software Client

SFC Visualization

6ES7 652-0XD07-2YB5

SFC Visualization

Simatic PCS 7 Safety Matrix OS Packages

Redundant operator systems

OS redundancy

Station/pair of servers

BCE

Connection to plant bus

Connection to terminal bus OS-LAN

Design of redundant OS single stations

Design of redundant OS servers

Expansion components for OS single stations / OS servers

Simatic NET S7

REDCONNECT/2006

OS archiving

Process values

Simatic PCS 7 Archive PowerPack

OS short-term archiving

Simatic PCS 7 Archive

OS long-term archiving with StoragePlus

StoragePlus

Hardware requirements

Software requirements

Simatic StoragePlus 6ES7 652-0XC21-2YB0

OS long-term archiving with Central Archive Server

Redundant design of central archive server

Single central Redundant Archive server Central archive

CAS

Overview of functions

Central archive server CAS

Additional components for redundant CAS

Operation and monitoring via Web

Simatic PCS 7 Web server

Simatic PCS 7 PowerPack Web Server

Simatic PCS 7 Web Server V7.0

Simatic PCS 7 OS Software 6ES7 658-2CX07-0YA5 Client V7.0

Simatic PCS 7 Web Diagnos 6ES7 658-2JX07-2YB0 Tics Client

OPC DA data access server

OPC HDA historical data access server

OPC A&E alarm & events server

OPC H A&E historical alarm & events server

OPC client access licenses to an OpenPCS 7 server

Data exchange with host systems

Multi-functional OpenPCS 7 server/OS client

Autonomous OpenPCS 7 server

Batch automation

Simatic Batch hardware Simatic Batch software Introduction

Design Integration

Integration in Simatic PCS

Communication with the automation systems

Client/server configuration

Simatic Batch hardware

Hardware for small plants

Redundancy

Batch single station

Simatic PCS 7 Industrial Work

Batch server

Simatic PCS 7 Industrial Work Station, server version

Simatic Batch software

Simatic

Function

Server Basic Package

Simatic Batch

Server Basic Package Units

PO Option

Batch Control Center

6ES7 657-0LX07-2YB5

BatchCC

Recipe System

6ES7 657-0AX07-2YB5 Recipe System

Batch Planning

6ES7 657-0BX07-2YB5

Batch Planning

Hierarchical Recipe

6ES7 657-0FX07-2YB0

Hierarchical Recipe

Separation Procedures/Formulas

ROP Library

Simatic Batch API

Simatic Route Control

Simatic Route Control

RC block symbols and faceplates

Route Control in the engineering system

Route Control Server/Route Control Center

Drop-down lists for location selection

Route Control Hardware

Requirements for selection of the automation systems

RC single station

RC server

RC client

Route Control runtime software

Route Control Server

Route Control Center RCC

Key functional features are

Simatic Route Control Server PowerPack

6ES7 658-7FB07-0YD0

6ES7 658-7FC07-0YD0

Route Control engineering software

Route Control library

Route Control wizard

Route Control Engineering tool

Simatic Route Control Engineering

Simatic Route Control

Introduction Maintenance station

Asset Management

Asset Management

Maintenance station

Simatic MS/ES

547B BCE/IE SRV03

Uniform symbols

Enhanced information for assets according to IEC

Information on passive or indirect assets

Typical sequence of a maintenance cycle

Asset engineering

Asset Management

Industrial Ethernet

Industrial Security

Other communication

Communication

Industrial Ethernet

Ethernet technology for industrial environment

OS LAN terminal bus

Industrial Ethernet plant bus

Decision aid for Industrial Ethernet switches

Scalance

Scalance X Industrial Ethernet switches

Profibus

Product characteristics

Summary of interfaces

IRT

Plug

Scalance X414-3E

Ethernet ports to fiber-optic conductors FOC

Industrial Ethernet glass multimode FOC see page 9/26 or

Features of the X-200 IRT switches

Type

Scalance X414-3E

Network size parameters / TP cable length

Permissible ambient conditions

Design

Scalance Scalance X308-2LD

Industrial Ethernet

Scalance X204 IRT Scalance X202-2 IRT Scalance X202-2P IRT

Scalance X201-3P IRT Scalance X200-4P IRT

Scalance Scalance X206-1LD

Scalance Scalance X212-2LD

With IE FC RJ45 Plug

Accessory for Industrial Ethernet switches

Plug

OSM/ESM/OMC Industrial Ethernet switches

Industrial Ethernet media converter

Industrial Ethernet OSM and ESM

Selection support for product versions of OSM and ESM

Scalance X101-1 Industrial

Ethernet media converter

Industrial Ethernet OSM ITP53 6GK1 105-2AD10

Scalance X101-1LD Industrial

Passive network components FastConnect

Connection elements

IE FC RJ45

Elements Plug 90/180 Modular Outlet

Documentation

Passive network components ITP cables and connectors

Electrical transmission media

Passive network components Fiber-optic cables

Optical transmission media

Fiber Optic

Other lengths and other fiber-optic cables can be found

Catalog IK PI

Supplementary components for the Simatic NET cable range

Support, please contact

System connection PCS 7 systems

Connection of single stations, servers and clients

Connection of automation systems

PCS 7 BCE

Simatic PCS 7 Redundant

System connection of automation systems

Simatic NET

Industrial Wireless LAN Iwlan

Scalance W746-1PRO Ethernet client module

Scalance W788-1PRO access point

Scalance

Access point

Accessories

Further information on country approvals

Stationary remote client

Industrial Security

Firewall

Configuration

Industrial Security components

Scalance S industrial security modules

Scalance S industrial security modules

Communication at field level with Profibus

Profibus transmission systems

Profibus DP

Electrical networks

FastConnect

Repeater for Profibus

Active RS 485 terminating element

Profibus connector with

RS 485-IS Coupler

Selectable terminating resistor

S7-300 rail

Optical networks with glass fiber-optic cables

Optical Link Module

Fiber Optic Cable

Profibus OLM/G12

Optical networks with plastic fiber-optic cables

OBT for Profibus DP

Profibus OBT

AS connection

Overview Selection and Ordering Data

CP 443-5 Extended 6GK7 443-5DX04-0XE0

PDM

PS 307 load power supply

PS 305 load power supply

Link

Link

Profibus PA

Ring architecture

Linear architecture with single coupler

Linear architecture with redundant couplers

Profibus PA

Routers DP/PA link and DP/PA coupler

Design High Speed solution with DP/PA link

DP/PA link

IM 153-2 High Feature for extended temperature range

DP/PA coupler

Communication

Communication

Active field distributor AFD and active field splitter AFS

FastConnect/SpliTConnect

SpliTConnect

Other communication

AS-Interface

System components

Modbus

Automation systems

Automation systems

10/2

Technical specifications

10/3

Microbox automation system

10/4

Design and equipment features

10/5

10/6

Electromagnetic compatibility EMC

Standard automation systems

10/7

10/8

6ES7

10/9

10/10

AS 414-3IE

10/11

Recommended preferred types

10/12

10/13

Simatic PCS 7 AS Runtime license

10/14

Ble

Fault-tolerant automation systems

10/15

10/16

Function

10/17

10/18

AS 412-3-2H Redundant Station 6ES7

10/19

AS 414-4-2H Redundant Station 6ES7

10/20

Single Stations, recommended preferred types

Automation systems

10/21

10/22

Automation systems

10/23

Selection and Ordering Data Order No Options

Safety-related automation systems

10/24

10/25

Redundant stations

Safety functions

10/26

10/27

AS 414F Single Station 6ES7

10/28

AS 417F Single Station 6ES7 AS 412FH Redundant Station

10/29

AS 414FH Redundant Station 6ES7

10/30

10/31

6ES7 656-8AB31-1EB0

10/32

Added to existing licenses

10/33

6ES7 952-1KP00-0AA0 6GK7 443-1EX11-0XE0

10/34

11/2 Introduction 11/4 Central I/O

11/6

Terminal module

11/9 ET 200M distributed I/O

11/2

Integration of I/O modules in the hazardous area

11/3

Possible online modifications among the process I/Os

Profibus PA

Simatic PDM

Central I/O

Central I/O modules

11/4

Expansion units for central I/O

11/5

Simatic PCS 7 MTA terminal module

11/6

Overview ET 200M redundant ET 200M single

11/7

11/8

Simatic PCS 7 MTA F-AI

Simatic PCS 7 MTA DI

Simatic PCS 7 MTA F-DI

ET 200M distributed I/O

11/9

Power supply

11/10

IM 153-2 High Feature 6ES7 153-2BA02-0XB0

IM 153-2 FO High Feature 6ES7 153-2BB00-0XB0

Interface modules

11/11

ET 200M accessories

11/12

Ex partition

LK 393 cable duct

Bundles

11/13

DI digital input modules

11/14

SM 321 for floating contacts supply with DC voltage

SM 321 for floating contacts supply with DC/AC voltage

SM 321 modules with diagnostics capability

IM 153-2 High Feature interface module required

11/15

For floating contacts supply with DC voltage

Do digital output modules

11/16

11/17

Outputs, 24 V DC / 0.5 a

Redundant design possible Module and channel redun Dancy

Outputs, 120/230 V AC / 2 a 6ES7 322-5FF00-0AB0

SM 323 for DC voltage suitable for switches, Bero proximity

Switches, solenoid valves, contactors, indicator lights etc

DI/DO digital input/output modules

11/18

AI analog input modules

11/19

11/20

Inputs in 4 channel groups 6ES7 331-7HF01-0AB0

Inputs in 4 channel groups 6ES7 331-7NF00-0AB0

Redundant design possible Module and channel redun

AO analog output modules

11/21

SM 332 modules for current and voltage outputs

Ex modules EEi xb

11/22

Modules with Hart

11/23

Parameterization

11/24

Modules

11/25

SM 326F failsafe digital input module for floating contacts

Inputs, Namur EEx ib

11/26

Isolating module

SM 336F failsafe analog input module

Closed-loop control modules

11/27

11/28

Integration Selection and Ordering Data Order No

Use in Simatic PCS

FM 355 C controller module 6ES7 355-0VH10-0AE0

Counter modules

11/29

FM 350-1 counter module 6ES7 350-1AH03-0AE0

CD-ROM

Exceptional features of the ET 200iSP architecture

ET 200iSP distributed I/O

11/30

11/31

Approvals, standards

Atex

Profibus

ET 200iSP power supply unit

11/32

IM 152-1 interface module

11/33

TM-IM/IM terminal module for

S7-300 rails

Electronics modules and watchdog module

11/34

Electronics modules

Watchdog module

11/35

Digital electronics modules

DI Namur

11/36

Analog electronics modules

Terminal modules

RS 485-IS coupler

11/37

Tasks of the RS 485-iS coupler

Connection to Profibus DP

Stainless steel wall enclosure

11/38

ET 200S distributed I/O

11/39

ATechnical specifications

ET 200S configuration

11/40

Mounting

Terminal Modules TM-P for Power Modules

Terminal modules

11/41

11/42

TM-E Terminal Modules for Electronic Modules

11/43

IM151-1 interface module

Power modules

PM-E power modules

PM-E F power modules

11/44

Digital electronics modules

11/45

…4CL20-0AA0 …4CG20

TM-E15N26 TM-E15N24 TM-E15N23

11/46

Analog electronics modules

11/47

TM-E terminal modules for electronics modules

TM-E15N26-A1 TM-E15N24-A1 TM-E15N24-01 TM-E15N23-01

11/48

Analog input

Analog output

6ES7 134-4NB01-0AB0

Motor starters

11/49

Brake control modules for motor starters

XB3 oder xB4 TM-xB215S24-01

High Feature motor starters

Safety-oriented motor starters

11/50

High Feature motor starters

11/51

Safety-related motor starters

11/52

Siguard safety technology

Possible combinations of power and terminal modules

11/53

PM-X

Terminal modules for Siguard power modules

Siguard PM-D F1/F2/F3/F4/F5 power modules

11/54

TM-X terminal module for Siguard connection module

Siguard Power Modules

11/55

Siguard Terminal Modules

PM-X Siguard

Dezentrale Peripherie ET 200pro

11/56

Modules of an ET 200pro station

Expansion modules

ET 200pro configuration

11/57

Module support

General technical specifications

11/58

Ambient conditions

Mechanical stress

Interface module IM 154-2 DP High Feature

Features of the IM 154-2 DP High Feature interface module

11/59

Connection modules

Digital electronics modules EM 141, EM

11/60

Digital input modules

Digital output modules

Analog electronics modules EM 144, EM

11/61

Analog output modules

Analog input modules

Further accessories

11/62

Safety-related electronics modules

Safety-related digital input module EM 8/16 F-DI PROFIsafe

11/63

11/64

Power module PM-E

Power module

11/65

Connection module

11/66

IT world

12/2

IT world

12/2

12/3

Integration of Simatic IT and Simatic PCS

Contact partners

12/4

Simatic PCS

13/2 Introduction

13/2

Migration strategy

13/3

Portfolio of the migration products

Migration component Description

13/4

Typical migration scenarios

13/5

Migration spectrum

Migration Support Center

Development of further migration products and tools

13/6

Ordering data for previous version Simatic PCS 7

14/2

Single station

Server

14/3

Client Additional and expansion components

IL43 WXP

Starter systems

14/4

PCS 7 Basic Package

Simatic PCS 7 PowerPacks for engineering software

ES software

14/5

Standard engineering software

14/6

TAG options / PowerPacks

14/7

Simatic PDM Single Point

Simatic PDM Basic

14/8

Controller optimization

Simulation with S7-PLCSIM

Applications

OS software

14/9

OS standard software for single station / server / client

Connectivity Pack and Client Access Licenses

Simatic Safety Matrix Viewer

14/10

OS archiving

14/11

OS redundancy

OS long-term archiving

Design of redundant OS single stations

Simatic Batch Software

14/12

PCS 7 Web Server

Route Control Software

14/13

Asset Management Software

14/14

Accessories

Profibus PA components

14/15

Asset Engineering

14/16

Components for hot swapping and for redundant design

Active bus modules for hot Swapping

BM DP/PA

Automation systems

14/17

Standard automation systems bundles

AS 414-3 automation system comprising

14/18

Fault-tolerant/safety-related automation systems bundles

14/19

14/20

S7 F Systems Runtime License

Update Upgrade packages

15/13 Simatic PCS 7 upgrades

Software Update Service

Software Update Service for Simatic PCS

Software Update Service for TIA products

15/2

Simatic PCS 7 Software Update Service

Software Update Service for TIA products

15/3

6ES7 658-1EX00-2YL8

15/4

Communications software/licenses for Simatic PCS 7

15/5

Simatic PDM upgrades

Simatic PDM upgrade/update service

15/6

Simatic PCS 7 upgrades V6.x to

Upgrades for engineering system

15/7

Upgrades for operator system

Upgrades of OS software

Upgrade of OS long-term archiving

Simatic PCS 7 OS Web upgrade

OS Web upgrade package

Upgrades of OS software from V6.0/V6.1 to

15/9

OS software

Upgrades for Simatic Batch

15/10

Simatic Batch packages for upgrading from V6.0/V6.1 to

Upgrades for Simatic Route Control

Simatic Route Control upgrade package

Simatic Route Control upgrade packages

Software Update Service Simatic Route Control

Upgrades for Asset Management

Simatic PCS 7 Asset upgrade

Simatic PCS 7 Asset upgrade

15/12

Simatic PCS 7 upgrades V4.02 to

Simatic PCS 7 upgrades V5.x/V6.0 to

15/13

Engineering system

Upgrades of OS software from V6.0 to

Upgrades of OS software from V5.x to

Upgrade of SFC Visualization

15/14

Simatic Route Control upgrade packages

15/15

Simatic PCS 7 upgrades V4.02 to

Engineering software upgrade for AS engineering

Engineering software upgrade for OS engineering

OS software upgrade

Appendix

Training

16/2

Siemens Contacts Worldwide

16/3

Online Services

Information and Ordering Internet and on CD-ROM

16/4

WWW

Our Services for Every Phase of Your Project

Customer Support

16/5

16/6

Small card great support

Siemens Solution Partner Automation and Power Distribution

16/7

Software Licenses

16/8

Subject index

16/9

16/10

10/24

Order no. index

16/11

16/12

16/13

6GK1 716-1CB64

16/14

16/15

Conditions of sale and delivery Export regulations

16/16

Terms and Conditions of Sale and Delivery

For customers with a seat or registered office in Germany

Automation and Drives Group A&D

Siemens AG