Chapter 2 Printer Installation

This section describes in detail how to adjust the media sensor positions and their sensitivity.

Whenever the type of media is changed, a positional adjustment of the media sensor is needed. The media sensors are designed to keep positional alignment of the image on each label or tag when issued.

Important!

NEVER skip the media sensor positional adjustment.

The printer has two types of media sensors: Black Mark Sensor and Feed Gap Sensor.

The Black Mark Sensor (reflective sensor) is used to detect black marks on the back of the media by the reflection of light. On the other hand, the Feed Gap Sensor (transmissive sensor) is used to detect gaps by the transmission of light.

Which media sensor to adjust depends on the type of media loaded.

When the media with black marks on the BACK is loaded, adjust the Black Mark Sensor (reflective sensor) position as follows:

1Open the Top Cover.

2Lift the Pinch Roller Lever to the ROLLER RELEASE position to open the Pinch Roller Unit.

3Align the Media Guides to the width of the media.

4Fold the media so that a black mark faces upward.

5Insert the media into the Media Inlet.

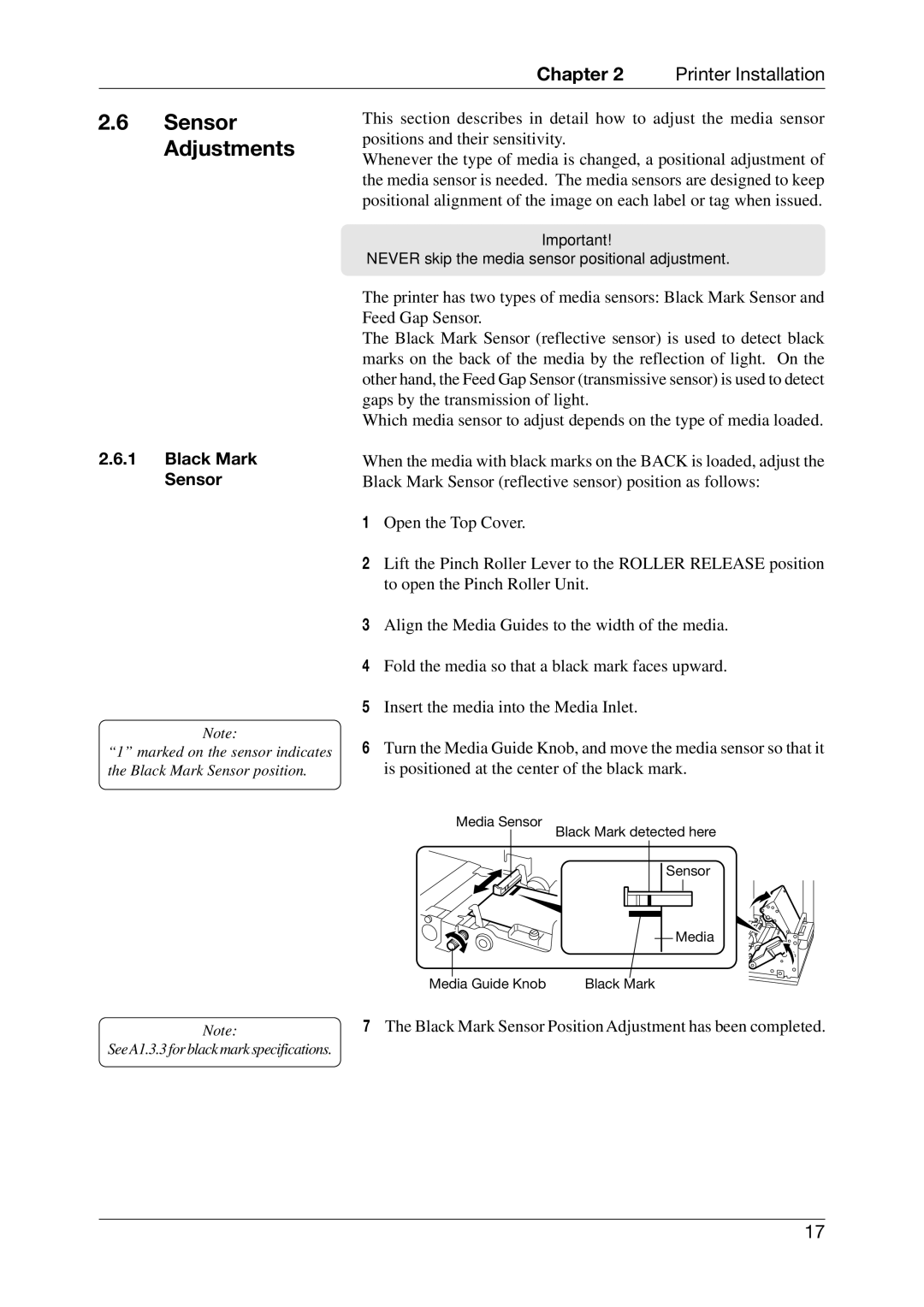

6Turn the Media Guide Knob, and move the media sensor so that it is positioned at the center of the black mark.

| Media Sensor | Black Mark detected here |

|

| Sensor |

|

| Media |

| Media Guide Knob | Black Mark |

Note: | 7 The Black Mark Sensor Position Adjustment has been completed. | |

See A1.3.3 for black mark specifications.

17