Appendix 1 | Specifications |

Name | Model | Description | |

|

|

| |

Cutter Module | Rotary cutter for cutting | ||

media without stopping | |||

|

| ||

|

|

| |

Ribbon Module | Spare ribbon module |

Please make sure that the media that will be used is approved by TOSHIBA TEC. The warranty does not apply when a problem is caused by using media that is not approved by TOSHIBA TEC.

For information regarding TOSHIBA

A1.3.1 Media Type

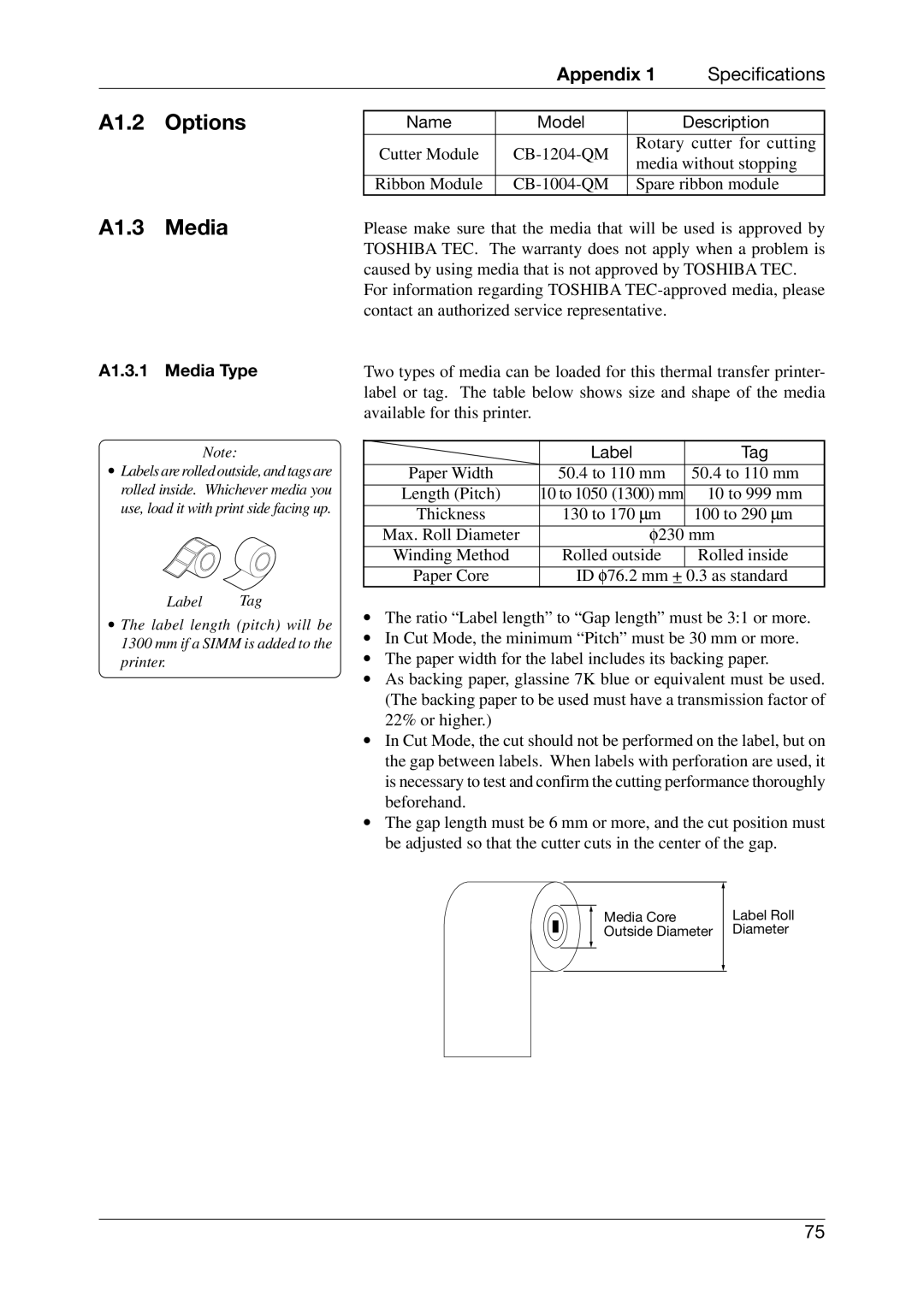

Note:

∙Labels are rolled outside, and tags are rolled inside. Whichever media you use, load it with print side facing up.

Label Tag

∙The label length (pitch) will be 1300 mm if a SIMM is added to the printer.

Two types of media can be loaded for this thermal transfer printer- label or tag. The table below shows size and shape of the media available for this printer.

| Label | Tag |

|

|

|

Paper Width | 50.4 to 110 mm | 50.4 to 110 mm |

Length (Pitch) | 10 to 1050 (1300) mm | 10 to 999 mm |

Thickness | 130 to 170 μm | 100 to 290 μm |

Max. Roll Diameter | φ230 mm | |

Winding Method | Rolled outside | Rolled inside |

Paper Core | ID φ76.2 mm + 0.3 as standard | |

∙The ratio “Label length” to “Gap length” must be 3:1 or more.

∙In Cut Mode, the minimum “Pitch” must be 30 mm or more.

∙The paper width for the label includes its backing paper.

∙As backing paper, glassine 7K blue or equivalent must be used. (The backing paper to be used must have a transmission factor of 22% or higher.)

∙In Cut Mode, the cut should not be performed on the label, but on the gap between labels. When labels with perforation are used, it is necessary to test and confirm the cutting performance thoroughly beforehand.

∙The gap length must be 6 mm or more, and the cut position must be adjusted so that the cutter cuts in the center of the gap.

|

|

| Media Core |

| Label Roll |

|

|

|

| ||

|

| ||||

|

|

| Outside Diameter |

| Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

75