Where to Find it - Online and Printed Information

User/Service and SCPI Programming Manual

E1441-90003

Agilent E1441A

Page

Edition

Contents

Chapter

Chapter

Appendix A

Chapter

Appendix B

Appendix C

Performance Verification Tests

6 Contents

DURATION OF WARRANTY: 1 year

AGILENT TECHNOLOGIES WARRANTY STATEMENT

Certification

U.S. Government Restricted Rights

Documentation History

Safety Symbols

Trademarks

WARNINGS

DECLARATION OF CONFORMITY

Safety

Measurement Product Generation Unit

Conforms with the following European Directives

Notes

Notes

Notes

Agilent E1441A

Module Setup

Function/Arbitrary Waveform Generator

Chapter

Setting the Module Address Switch

Figure 1-1.Setting the Logical Address

Chapter

Interrupt Priority

Installing into the Mainframe

Faceplate Indicators

Faceplate Indicators and Connectors

Option 001 Phase-Lock10 MHz Reference Terminals

Standard Input/Output Terminals

Initial Operation

Chapter

Agilent E1441A Application Information

Output Configuration

Functional Capabilities

Chapter

Valid Function/ Modulation Modes

FUNCtion:SHAPe SIN|SQU|TRI|RAMP|NOIS|USER|DC

Table

Table

Chapter

FREQuency <frequency>|MINimum|MAXimum

Table

22 Agilent E1441A Application Information

Chapter

Parameter

Page

Use the following command to set the dc offset

Use the following command to set the duty cycle

sync signal, you can disable the Sync terminal

AM Carrier Waveform Shape

Amplitude Modulation AM

Amplitude Modulating Waveform Frequency

Amplitude Modulating Waveform Shape

Amplitude Modulation Depth

FREQuency <frequency>|MINimum|MAXimum

Amplitude Modulating Source

Frequency Modulation FM

FM Carrier Frequency

FM Carrier Waveform Shape

FM Peak Frequency Deviation

32 Agilent E1441A Application Information

Chapter

•“Burst Modes” on page

“Burst Phase” on page

“Counted Burst Mode” on page

“Gated Burst Mode” on page

The command sequence to configure this mode is

The command sequence to configure this mode is

trigger source

34 Agilent E1441A Application Information

Burst Trigger Source For Counted Burst Mode

Gated Burst Mode

INTernal

IMMediate

EXTernal

TTLTRG<n>

Minimum Frequency

Number of Arb Points

Maximum Frequency

Carrier Frequency

Burst Count

Use the following command to set the burst rate

Use the following command to set the burst count

BM:NCYCles <# cycles>|INFinity|MINimum|MAXimum

BM:INTernal:RATE <frequency>|MINimum|MAXimum

•“FSK Carrier Frequency” on page

Frequency-Shift Keying FSK Modulation

•“FSK “Hop” Frequency” on page

•“FSK Rate” on page •“FSK Hop Source” on page

Use the following command to set the FSK rate

Use the following command to set the frequency

FREQuency <frequency>|MINimum|MAXimum

FSKey:FREQuency <frequency>|MINimum|MAXimum

External Hop Source

Internal Hop Source

42 Agilent E1441A Application Information

Chapter

•“Sweep Start and Stop Frequencies” on page

Sweep Start and Stop Frequencies

•“Sweep Time” on page •“Sweep Mode” on page

•“Sweep Trigger Source” on page

Internal Source

Sweep Trigger Source External Sources

Figure 2-9.Frequency Sweep with Internal Trigger

Sweep Trigger Signal TRIG:SOUR INT shown

TRIGger:SOURce IMMediate|EXTernal|TTLTRG<0-7>|BUS

Chapter

Creating Arbitrary Waveforms

Arbitrary Waveforms

Creating and Storing an Arbitrary Waveform

Figure

Waveforms

48 Agilent E1441A Application Information

Chapter

APPL:SIN 10E+6,

Phase-Lock Capabilities Opt

PHAS:ADJ

90DEG

requires Option

To Phase Lock Multiple Function Generators

Figure

50 Agilent E1441A Application Information

To Phase Lock Using the Counted Burst Mode

Send these commands to both function generators

requires Option

Triggering the Function Generator

Trigger Slope

Trigger Source Choices

External Triggering Including TTLTRG lines

Internal Triggering

Trig / FSK / Burst Input Terminal” on page

Software BUS Triggering

Figure

Ext Trig / FSK / Burst Input Terminal

54 Agilent E1441A Application Information

Chapter

System-RelatedOperations

SCPI Language Version Query

Firmware Revision Query

Reset State

Power-Onand

Feature

Power-Onand Reset State

CLanguage Programs Compiling and Linking a C

Application Program Examples

Program Example Programs

Burst Modulation Program

Chapter

Agilent E1441A Application Information

iferr != VI_SUCCESS err_handlerfuncgen, err

AM Modulation and Instrument State Storage

60 Agilent E1441A Application Information

Chapter

Arbitrary Waveform Example

Chapter

Agilent E1441A Application Information

Chapter

62 Agilent E1441A Application Information

Chapter

end of main Error handling function

Agilent E1441A Application Information

close the device session */ viClosefuncgen

Chapter

64 Agilent E1441A Application Information

Agilent E1441A SCPI Command Reference

Command Index by Function

Chapter

Modulation Commands

66 Agilent E1441A SCPI Command Reference

Chapter

Arbitrary Waveform Commands

Sweep Commands

Trigger Commands

Agilent E1441A SCPI Command Reference

Calibration Commands

System-RelatedCommands

Status Reporting Commands

68 Agilent E1441A SCPI Command Reference

Option 001 Phase-LockCommands

The IEEE-488.2Common Commands

Agilent E1441A SCPI Command Reference

Chapter

Common Command Format

Command Fundamentals

SCPI Command Format

Abbreviated Commands

Linking Commands

Implied Commands

Parameters

Command Guides

SCPI Command Reference

CALibration?

CALibration

COUNt?

Subsystem Syntax

SECure:CODE

SECure:STATe

Parameters

SETup?

SETup

SECure:STATe?

STRing

VALue

STRing?

VALue?

Parameters

DATA

VOLATILE

Subsystem Syntax

DAC VOLATILE

ATTRibute:AVERage?

ATTRibute CFACtor?

Downloading a Binary Block of Data

ATTRibute PTPeak?

ATTRibute:POINts?

80 Agilent E1441A SCPI Command Reference

Chapter

COPY

CATalog?

Agilent E1441A SCPI Command Reference

Chapter

DELete

DEL:ALL

NVOLatile:CATalog?

NVOLatile:FREE?

BORDer

FORMat

BORDer?

•Related Commands

STATe:DELete

MEMory

STATe:RECall:AUTO

•Related Commands: *RCL, *SAV

Comments • Returned Value: 0 or

STATe:RECall:AUTO?

LOAD

OUTPut

LOAD?

Parameters

SYNC?

SYNC

TRIGger:IMMediate

TRIGger:STATe

Agilent E1441A SCPI Command Reference

TTLTrg<n>:STATe?

enable TTLTRG2 line to source a trigger

enable TTLTRG7 line to source a trigger

ADJust

PHASe

Subsystem Syntax PHASe

Only valid with Option

UNLock:ERRor:STATe

ADJust?

UNLock:ERRor:STATe?

REFerence

92 Agilent E1441A SCPI Command Reference

SOURce

Subsystem Syntax

Chapter

AM:DEPTh

Amplitude Modulation AM Commands

Parameters

•*RST Condition: 100%

AM:INTernal:FUNCtion

AM:DEPTh?

AM:INTernal:FUNCtion?

AM:INTernal:FREQuency

AM:STATe

AM:SOURce?

AM:STATe?

•*RST Condition: BOTH

APPLy Commands

APPLy Command Parameters

Syntax

in the waveform see below

Chapter

98 Agilent E1441A SCPI Command Reference

±10 Vdc into an open circuit

APPLy NOISe

APPLy:DC

APPLy:RAMP

APPLy:SINusoid

APPLy:TRIangle

APPLy:SQUare

APPLy:USER

APPLy?

BM:NCYCles

BURST MODULATION COMMANDS

BM NCYCles?

BurstCount

BM:PHASe?

BM:PHASe

BM:INTernal:RATE

Parameters

BM:INTernal:RATE?

FM COMMANDS

BM:SOURce

BM:SOURce?

FM:DEViation?

FM:DEViation

FM:INTernal:FREQuency

Parameters

FM:INTernal:FUNCtion

FM:INTernal:FREQuency?

FM:INTernal:FUNCtion?

FM:STATe

FREQuency:STARt

FREQuency?

Agilent E1441A SCPI Command Reference

Parameters

FREQuency:STARt?

Frequency-ShiftKeying FSK Commands

FREQuency:STOP

FREQuency:STOP?

FSKey FREQuency?

FSKey:FREQuency

FSKey INTernal RATE

FSKey:INTernal:RATE?

FSKey:SOURce?

Selecting an Arbitrary Waveform

FSKey:STATe

FSKey:STATe?

FUNCtion:SHAPe

FUNCtion:USER?

Agilent E1441A SCPI Command Reference

Chapter

PULSe:DCYCle

FUNCtion:SHAPe?

112 Agilent E1441A SCPI Command Reference

Parameters

SWEep:SPACing

PULSe:DCYCle?

SWEep:SPACing?

SWEep:TIME

SWEep:STATe?

SWEep:STATe

VOLTage

114 Agilent E1441A SCPI Command Reference

VOLTage:OFFSet

VOLTage?

Agilent E1441A SCPI Command Reference

Parameters

VOLTage:OFFSet?

VOLTage:UNIT

VOLTage:UNIT?

STATus

PRESet

QUEStionable :CONDition?

QUEStionable :EVENt?

QUEStionable :ENABle?

QUEStionable :ENABle

Agilent E1441A SCPI Command Reference

Figure

Chapter

SYSTem

ERRor?

VERSion?

Subsystem Syntax

SLOPe

TRIGger

SLOPe?

SOURce

the *TRG IEEE-488.2common command

Related Commands *RST Condition TRIG SOUR IMM

SOURce?

Command

IEEE 488.2Common CommandReference

124 Agilent E1441A SCPI Command Reference

Category

ESR?

ESE?

Comments • Coupled command: No

•Related Commands: STATus:PRESet

OPC?

IDN?

OPT? option

Comments • Coupled command: No

•Coupled command: No

PSC?

Comments • Coupled command: No

•*RST Condition: none

Comments • Coupled command: No

•Coupled command: No

Power-OnCondition no bits are enabled

Parameters

STB?

SRE?

TST?

Comments • Coupled command: No

Feature

Agilent E1441A Power-Onand Reset State

Power-Onand Reset State

130 Agilent E1441A SCPI Command Reference

SCPI Command Quick Reference

Agilent E1441A SCPI Command Reference

Chapter

Chapter

132 Agilent E1441A SCPI Command Reference

Agilent E1441A SCPI Command Reference

SOURce

Chapter

Chapter

134 Agilent E1441A SCPI Command Reference

Appendix A

Agilent E1441A Specifications

Sinewave Spectral Purity

Frequency Characteristics

Output Characteristics 1,5 Amplitude into 50Ω:2

Signal Characteristics Square wave

Resolution

Triangle, Ramp, Arb

Modulation

Characteristics

Frequency Sweep

Faceplate Inputs5

Arb Download Times

System Characteristics Configuration Times

Cooling/Slot

Operating Environment

Phase Offset

Option 001 Specifications Timebase Accuracy

Faceplate Output: Ref Out terminal

Trigger

Appendix A

140 Agilent E1441A Specifications

Execution Errors

Agilent E1441A Error Messages

Appendix B

102 Syntax error

109 Missing parameter

108 Parameter not allowed

112 Program mnemonic too long

113 Undefined header

151 Invalid string data

170to -178 Expression errors

158 String data not allowed

161 Invalid block data

221 Settings conflict; offset has been adjusted

221 Settings conflict; frequency has been adjusted

222 Data out of range; amplitude

222 Data out of range

222 Data out of range; frequency

222 Data out of range; offset

550Command not allowed in local

350 Too many errors

580Phase-lockedloop is unlocked

440 Query UNTERMINATED after indefinite response

Calibration Errors

Self-TestErrors

590I/O processor reset 601Trigger test failed

701Cal security disabled by jumper

702Cal secured

707Cal signal measurement out of range

703Invalid secure code

704Secure code too long

850Cal setup invalid

Arbitrary Waveform Errors

851Negative offset gain cal required CAL:SETup

852Flatness DAC gain cal required CAL:SETup

785Specified arb waveform does not exist

783Arb waveform name too long

786Cannot delete a built-inarb waveform

788Cannot copy to VOLATILE arb waveform

580Phase-lockedloop is unlocked

Option 001 Phase-LockErrors

Appendix B

152 Agilent E1441A Error Messages

Agilent E1441A Function Generator Tutorial

Appendix C

Direct Digital Synthesis

Figure C-3

Figure C-2

154 Agilent E1441A Function Generator Tutorial

Appendix C

Signal Imperfections

Appendix C

Agilent E1441A Function Generator Tutorial

Figure C-4

Output Amplitude Control

Figure C-5

156 Agilent E1441A Function Generator Tutorial

Attributes of AC Signals

Floating Signal Generators

Appendix C

Agilent E1441A Function Generator Tutorial

1 + D ⋅ Am 〈 t〉 ⋅ sin2π ⋅ Fc ⋅ T

Modulation

158 Agilent E1441A Function Generator Tutorial

Appendix C

Agilent E1441A Function Generator Tutorial

Appendix C

For wideband FM

Start Frequency + Stop Frequency

Deviation = Hop Frequency – Carrier Frequency

160 Agilent E1441A Function Generator Tutorial

Appendix C

for AM

Table C-1

624for FM

Appendix C

Points P = C/S / Fs =

Fs = 1 / 9 x 200 ∝s = 555.555 kHz

y = mX + b

162 Agilent E1441A Function Generator Tutorial

Appendix D

Service Procedures

Automated Verification and Calibration Procedures

Agilent Technologies Calibration Services

Closed-CaseElectronic Calibration

Calibration Interval

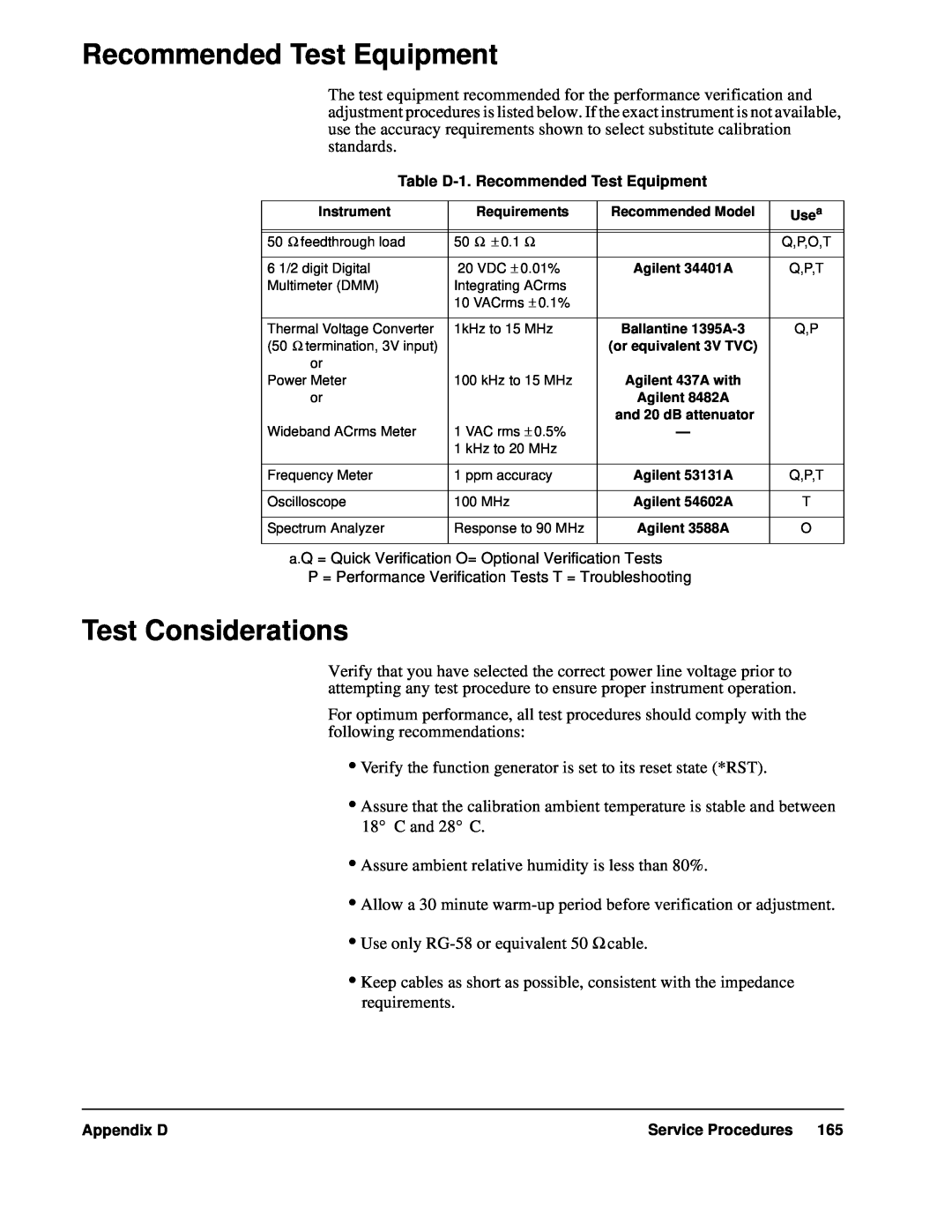

Test Considerations

Recommended Test Equipment

Performance Verification Tests

Frequency Verification

Quick Performance Check

Performance Verification Tests

DC Function Offset Verification

Function Gain and Linearity Verification

168 Service Procedures

Table D-4.DC Function Offset Verification

Service Procedures

AC Amplitude Verification

Table D-5.AC Amplitude Verification High Z

Appendix D

170 Service Procedures

Table D-6.AC Amplitude Verification 50 Ohms

Appendix D

Service Procedures

Amplitude Flatness Verification

Table D-7.Amplitude Flatness Verification

Appendix D

AM Modulation Depth Verification

Optional Performance Verification Tests

Square Wave Duty Cycle Verification

Service Procedures

Distortion Verification

Table D-10.Distortion Verification

Appendix D

To unsecure for calibration

Calibration Security Code

To re-secure

To change security code

Unsecuring the Function Generator

Calibration Message

Calibration Count

Calibration Example

General Calibration/Adjustment Procedure

Aborting a Calibration in Progress

Frequency and Burst Rate Adjustment

Function Gain and Linearity Adjustment

AC Amplitude Adjustment High-Z

Modulation Adjustment

Table D-15.50 Ohm Adjustment Setup

AC Amplitude Adjustment 50 Ohms

182 Service Procedures

Appendix D

Table D-16.AC Amplitude 50 Ohms Adjustment Setups

7.Repeat steps 4, 5 and 6 for SETUP 35 through

Service Procedures

8.Perform the “AC Amplitude Verification” on page

DC Output Adjustment

AC Amplitude Flatness Adjustment

Duty Cycle Adjustment

1 kHz to 100 kHz

Table D-22.AC Flatness Adjustment Setups

Service Procedures

Appendix D

Table D-23.System Error Messages

Error Messages

Table D-24. Self-TestError Messages

188 Service Procedures

Table D-25.Calibration Error Messages

Service Procedures

Appendix D

Test Limits Measurement Uncertainty

Performance Test Record

Test Accuracy Ratio TAR

MaximumValue – ExpectedReading

Appendix D

Test Equipment Used Description

Appendix D

Model No

Trace No

Agilent E1441A Function Gain and Linearity

Agilent E1441A Frequency Accuracy

Agilent E1441A DC Function Offset

Appendix D

Appendix D

Agilent E1441A AC Amplitude High Z

Appendix D

Agilent E1441A AC Amplitude 50 Ohms

Agilent E1441A Amplitude Flatness

Agilent E1441A AM Modulation

Appendix D

Agilent E1441A Square Wave Duty Cycle

Optional Performance Verification Tests

Agilent E1441A Distortion

Appendix D

Appendix D

Index

Symbols

CODE, STATe,

AVERage?, CFACtor?, POINts?, PTPeak?,

ALL,

CATalog?, FREE?,

IDN?, 124,

OPC, 124, 126 *OPC?

FM, 32, FSK, 41,

ERRor STATe, STATe?,

DELete,

RST, 124,

SRE?, 124,

STB?, 124,

DEPTh, DEPTh?, INTernal FREQuency, FUNCtion,

WAI, 124,

Vpp, 25, Vrms, 25,