MN1274 06/2001

Installation Manual

Page

Iii

Safety Notice

Circuit amperes listed here at rated voltage

Page

Contents

Viii

Input / Output

Mint WorkBench

Appendices

Tuning

129

Xii

Introduction

MintDrive features

Meaning Alternatives

Receiving and inspection

Identifying the catalog number

Date

Ready LED

MintDrive indicators

Monitor LED display

Can 1 and 2 LEDs

Units and abbreviations

Each step should be followed in sequence

You must read all the sections in Basic Installation

Outline

Hardware requirements

CBL

Tools and miscellaneous hardware

Power sources

Other information needed for installation

2 RS485 / RS422 systems

Mechanical installation and location requirements

Package dimensions

Dimensions and mounting

Power connections

MintDrive

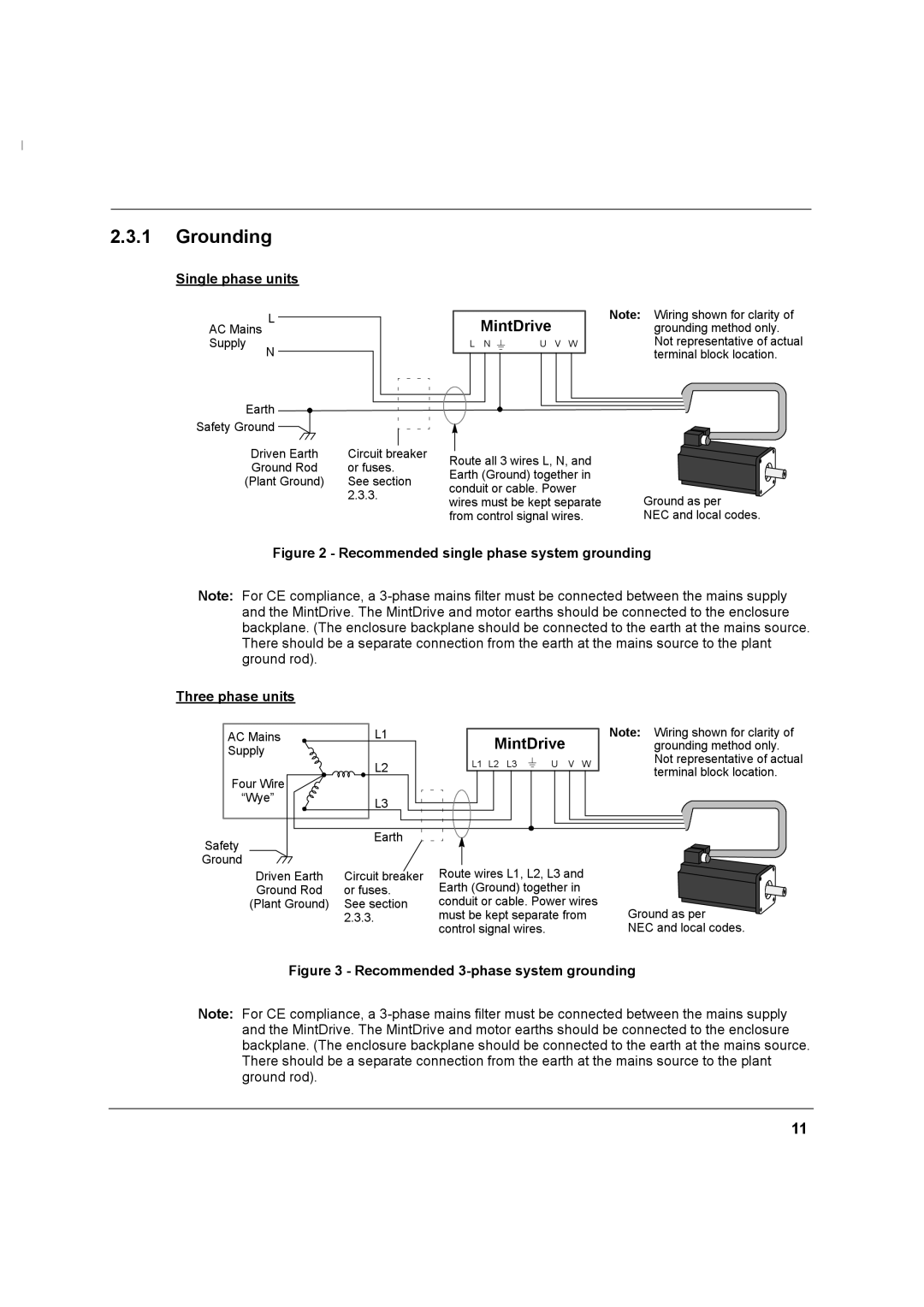

Single phase units

Grounding

Ungrounded distribution systems

Input power conditioning

Power disconnect and protection devices

Circuit breaker and fuse, single phase, package size C

Delay

Wire sizes

Single phase connection to package size C

Single phase connection to package size a or B

Input current

Three phase connection to package size C

8 24V control supply

External drive

DC Bus power connections from package size C

Output voltage

MintDrive

Power supply filters

Nominal output voltage

Motor connections

Motor circuit contactors

Baldor regeneration resistor catalog numbers

Regeneration resistor Dynamic Brake resistor

Regeneration resistor mounting

Feedback connections

Baldor Motor

Resolver option

Pin Resolver function

Signal name Motor / cable Resolver cable wire Pin Color

Resolver cable pin configuration

Pin Encoder function

Encoder option

This completes the basic installation

Drive enable

Analog I/O

Input / Output

Description

Analog Input, Single Ended

Mint keyword

ADC.2

ADC.3

Analog Input, Differential

ADC.0 ADC.1

Pins Name

Analog Inputs, Differential

Page

AUXDAC.2 AUXDAC.3

Analog Outputs, Bipolar

AOUT0 and AOUT1 analog outputs

AUXDAC.0 AUXDAC.1

Digital I/O

External +24VDC supply Active high =+24VDC =0V Active low

Digital Inputs

Pin Name Mint keyword

X13

Thermal switch connection

X5 Digital inputs

External +24VDC supply Active high A=+24VDC B=0V Active low

Input Function

Special functions on inputs DIN0 and DIN2

Breakout board

OUT.7

Digital Outputs

OUT.5

OUT.6

OUT.3

OUT.4

OUT.2

OUT.0

MintDrive NextMoveBX encoder input

Other I/O

Simulated encoder output

Pin Name

Differential encoder connections

Master auxiliary encoder input

Auxiliary encoder circuit

Pin RS232 Name RS485 / RS422 name

Serial port

RS232 serial port connections

Using RS232 cable

Master Controller

Multidrop using RS485 / RS422 cable

Baldor HMI PLC Port

Connecting Baldor HMI Operator Panels

Can peripherals

Optional breakout board for connector

Installing the software

Connecting the MintDrive to the PC

Starting the MintDrive

Mint Configuration Tool Startup Wizard coarse tuning

Page

Page

An introduction to closed loop control

MCT Startup Wizard fine-tuning

Page

Fine-tuning the speed loop

Fine-tuning the position loop

Click Start Move

Jog test

Completing the Startup Wizard

Click Mint Configuration Tool in Wizard Mode

Digital input configuration

MCT Wizard hardware configuration

Digital output configuration

Axis0 error configuration

Axis0 parameter configuration

Miscellaneous configuration

Axis0 tuning configuration

Completing the configuration wizard

Page

Mint WorkBench

Completing configuration

Standard toolbar functions

Using WorkBench

Selecting the controller

Menus and buttons

Can window

Motion toolbar functions

Macro toolbar functions

Status bar

Quick Watch tab

Watch window

740 × L × A∕V

Speed Loop tab

Position Loop tab

Capture tab

Program window

Configuration window

Editor windows

To stop the motor turning, type

Useful commands for testing

Terminal window

To start the motor turning slowly, type

To change the speed, type

Combining commands on one line

To turn a distance of 5 turns, type

Prog

Firmware update

CON

NEW

Page

General specifications

Specifications

Power

Resolver feedback

Rectifier and regeneration

Encoder feedback

Control signals

Environmental

Page

Problem diagnosis

Troubleshooting

Communication

Problem Check

Corrupted. Use Release

Power up

Data Defaulting to

Tuning

Mint gains

Config = cfCURRENTAMPLIFIER

Ready LED is red

Print Drivefault

Code Problem Check

Parameter

Code Problem Check

7 can

Problem Check

Page

Purpose Name Abbreviation / keyword

Tuning a Introduction

Figure A.1 MintDrive Closed Loop System

Closed loop control

100

Position loop

101

Speed loop

Current loop

MintDrive operational modes

102

Tuning the position loop for a velocity servo drive

Tuning the position loop for a servo drive

Position Loop gain terms

KINTMODE=2

103

104

Position Loop Tuning using a step move

Position Loop Tuning using a trapezoidal move type

105

Tuning the position loop for a torque servo drive

Saving tuning information

CONFIG=6

106

Cable length Maximum bit rate Resistance Conductor area

MintDrive capabilities

107

108

Pin Name Description

Can 1 CANopen

Can 1 CANopen

109

Type Mint Constant Node Type

What is CANopen?

110

111

Configuring nodes

Network manager node

Scanning nodes

? NODELIVE.1.2 ? NODETYPE.1.2

Connecting to nodes

112

Event Number Mint Constant

Monitoring can events

113

114

Controller nodes

Singlecast communication

Broadcast communication

115

Digital I/O access

9 I/O nodes

Comms array subroutines

116

Analog I/O Access

Extra Analog I/O Functionality

REMOTEADCDELTA.1.2.3 =

HMI Operator Panels

117

118

119

Can 2 Baldor can

Can 2 Baldor can

120

Connecting the PC, MintDrive and can peripheral

Preparing the MintDrive

Preparing the can peripheral

Node IDs

Static configuration

Node type Type Mint Constant Default Node ID Baud rate

Remotesetup

NODETYPE.7 =

Adding the node to the network

122

123

Monitoring can Bus communications

Controlling the can peripheral

Normal operation

Pause NODELIVE.14

KeypadNode

124

BUS=2

125

IoNode 24/24

View NODELIVE.2

Example can network

126

NODESCAN.0

Keyword Abbreviation

Using abbreviations

Mint can related keywords

127

128

129

Declaration of Conformity

130

EMC wiring technique

EMC Conformity and CE marking

Use of CE compliant components

Grounding Earth

EMC installation suggestions

131

EMC filters

132

Wiring of shielded screened cables

Figure C.4 Handwheel Encoder cable grounding

Figure C.5 Encoder signal cable grounding

134

135

Cable Cable assembly Baldor catalog number Length

Cables

136

Resolver feedback cable

137

Filter dimensions FN351-36-33 and FN351-50-33

EMC mains filters

Catalog numbers

138

Dimensions inches mm

Dimension FN2070-6-06

115VAC drives 230VAC drives Baldor

Regeneration resistors

139

Baldor catalog number MintDrive

140

Breakout board

Page

MN1274 06/2001