SM-PRN001

Model HL-1030/1240/1250/1270N

Page

Preface

Table of Contents

Theory of Operation

Disassembly and RE-ASSEMBLY

Troubleshooting

Periodic Maintenance

Index

Manufacturedc

Manufacturedk

For Finland and Sweden

IEC 825 220-240V Model only

Achtung

Safety Information

Definitions of WARNINGS, Cautions and Notes

High Resolution and Fast Print Speed

Features

Quick Print Setup

Versatile Paper Handling

Environment-Friendly

Enhanced Memory Management

Network Feature for HL-1270N only

Bar Code Print for HL-1250/1270N only

Isbn UPC-A UPC-E EAN-8

Front View

Overview

Rear View HL-1030/1240

HL-1250/1270N

Specifications

Printing

DIB

CPU

Functions

Electrical and Mechanical

Network for HL-1270N only

Paper

Feedable paper

General

Print delivery

Paper cassette capacity

Print guaranteed area

Printing Area

Effective printing area

Monarch

COM10

Conditions Required for Installation

Power Supply

Environment

Unpacking

For Windows Users

Install the Printer

Installation and Basic Operation

For Windows Users with No CD-ROM Drive

Install the drum unit

Load paper

Print a test

Connect the printer and the computer

Install the printer driver from floppy disk

Using the USB Interface for Windows 98 only

Install the USB driver

Connect the USB interface cable

Installation and Basic Operation

Set the PC printer port

For Macintosh iMac and Power Macintosh with USB Users Only

Paper Handling

Load Paper into the Paper Cassette

Load Paper Manually

To print on both sides of the paper from the paper cassette

Two Side Printing Manual Duplexing

Installation and Basic Operation

Control Panel Operation

Alarm

Drum Ready

Data

Alarm LED Indications

Data Toner LED Indications

Drum LED Indications

Sleep mode

Other Control Features

Control Panel Button Operations

Operation Description

Test print mode

Network Board Operation for HL-1270N only

Preparing the BR-net Board

Connect the Ethernet cable

Factory default setting

Print configuration

LED functions

LED green Link activity

Electronics

General Block Diagram

RAM 4MB

HL-1250

HL-1270N

Shows a general block diagram of the HL-1270N printer

Main PCB Block Diagram

USB I/O

CPU Core Reset Circuit

Asic HL-1030/1240

Main PCB

HL-1250/1270N

Theory of Operation

2 ROM HL-1030/1240

Two 32 Mbits ROMs x 16 bit are fitted

Dram HL-1030/1240

Flash ROM for HL-1270N only

Two 16M-bit DRAMs x 16 bits are used as the RAM

Optional RAM HL-1250/1270N

PCI bus HL-1270N

Optional serial I/O HL-1250

Eeprom HL-1030/1240

Reset circuit HL-1030/1240

Engine I/O HL-1030/1240

BR-net PCB for HL-1270N only

Engine PCB

Low-voltage power supply

GND

High-voltage power supply

Overview of Printing Mechanism

Mechanics

PCB

Paper Transfer

Paper supply

Paper registration

Sensors

Paper eject

Cover sensors a and B

Toner Cartridge

Drum Unit

Print Process

Charging

Exposure stage

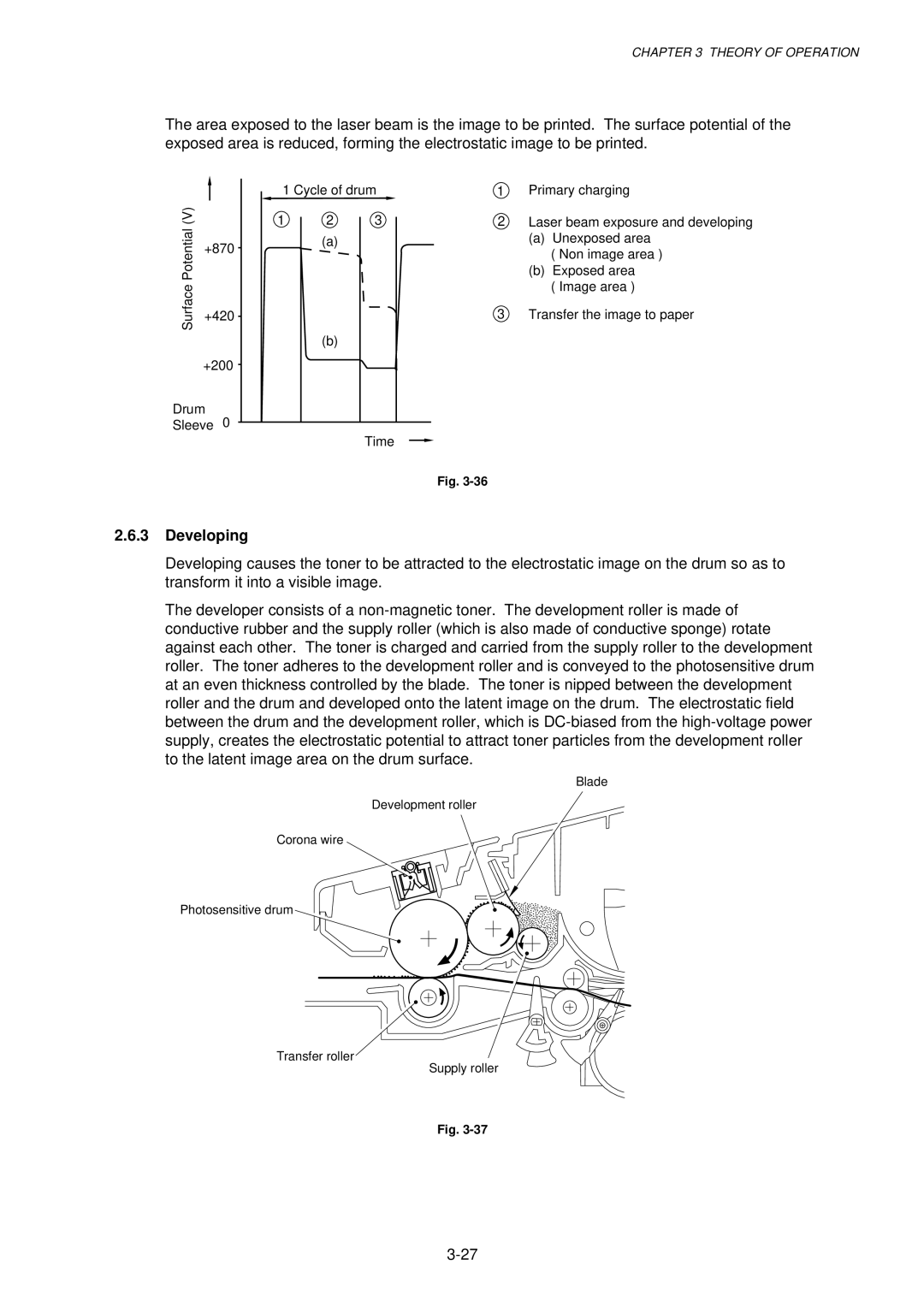

Developing

Fixing stage

Transfer

Safety Precautions

TAPTITE, CUP S

Screw

PCBs

Disassembly Flow

AC Cord

Disassembly Procedure

Paper Cassette

Taptite, Torx pan M3x8

Disassembly and RE-ASSEMBLY

Side guide L Side guide R Paper cassette

Paper cassette Release lever extension spring Lock lever

➀ ➁

Network Board for HL-1270N only

Front Cover

Top Cover

Main Cover

Tray extension flap Main cover

Laser Unit

Drive Unit

Main motor Assy Grease Molykote PG-662 1 rice-grain size

Fixing Unit

Fixing unit Main frame Concavity

Remove the fixing unit cover from the fixing unit frame

Halogen lamp Taptite, pan M3x10

Heat roller bearing Washer Heat roller gear

Heat roller gear Heat roller bearing Embossment

Heat roller cleaner Fixing unit frame Cleaner spring

Hooks Thermistor Fixing unit frame Taptite, cup M3x12

Fixing unit frame First eject roller Idle gear

PR2000057

26B

Base Plate

Ground wire Plastic chute Slit Main frame

Lower Tray Relay PCB Assy for HL-1250/1270N only

Main PCB Assy

Low-Voltage Power Supply PCB Assy

30A

PCB Assy

Engine PCB Assy / High-Voltage Power Supply PCB Assy

Toner sensor light

Solenoid Assy

Panel PCB Assy

Clutch lever spring For paper feed roller

Step Cassette guide L/F Taptite, cup M3x6

Fan Motor Assy

Toner Sensor PCB Assy Light Reception

Toner Sensor PCB Assy Light Emission

Paper Pick-up Roller Assy

Paper Feed Roller Assy

70a

Outer Chute

Packing

Consumable Parts

Replacement Procedure

Toner Cartridge

Periodic Maintenance

Assy

Periodical Replacement Parts

Periodical Cleaning

Cleaning the Printer Exterior

Cleaning the Drum Unit

Clean the Electrical Terminals

Cleaning the Scanner Window

Mtbf / Mttr

Periodic Maintenance

Initial Check

Introduction

Troubleshooting

Printer does not print Printed page has a problem

Identify the Problem

Service Calls

Operator Calls & Service Calls

LED Indication Error Remedy

Operator Calls

How the LEDs indicate an error

See ‘M-11 Service B’

Error Messages

Error Messages in the Status Monitor

Error Message Remedy

NV-RAM Error

RAM Error

Main Motor Error

Error

Error Message Printouts

Paper Problems

Paper Loading Problems

Problem Remedy

Clearing jammed paper

Paper Jams

Causes & countermeasures

Problem Type of Jam Cause Remedy

Double feeding

Paper Feeding Problems

Wrinkles or creases

User Check

Curl or Wave

Skew

Subsection 10.1 ‘Test Print

Software Setting Problems

Unable to print from application software under DOS

HL-1240/1250/1270N only

Value or alphabet following ‘BR’ is a product ID

No DC power supplied

No AC power supplied

Malfunctions

PCB

No paper supplied

Main motor does not rotate

Insufficient output from high-voltage power supply unit

Fixing heater temperature failure

BD failure

Scanner failure

Fuser failure

PCB 24V DC?

ROM error / D-RAM error / NV-RAM error

Engine interface error

PCI BUS error HL-1270N only

Image Defect Examples

Image Defects

Light

Troubleshooting Image Defect

Dark

Completely blank

All black

Dirt on the back of paper

How to clean the pressure roller

Black and blurred vertical streaks

Black vertical streaks in a gray background

Black and blurred horizontal stripes

White horizontal stripes

White vertical streaks

Poor fixing

Faulty registration

Faint print

Image distortion

White spots

Photosensitive drum

Black band

Black spots

Hollow print

Gray background

Horizontal lines

Downward fogging of solid black

Ghost

Light rain

Toner specks

Location of Grounding Contacts

Drum unit

Printer body & Paper cassette

Printer prints unexpectedly or it prints garbage

Incorrect Printout

For HL-1250/1270N only

User Check For DOS environment only

User Check For connecting by RS-232C/422A on HL-1250 only

Installation Problem

Network Problem for HL-1270N only

Intermittent Problem

Unix Troubleshooting

TCP/IP Troubleshooting

Windows 95/98 Peer to Peer Print LPR Troubleshooting

Windows NT/LAN Server TCP/IP Troubleshooting

Internet Print TCP/IP Troubleshooting

AppleTalk Troubleshooting

Novell Netware Troubleshooting

Apple TCP/IP Printing System 8.6 or later

Web Browser Troubleshooting TCP/IP

Test Print Mode

Inspection Mode

Type of mode Function

For the demo printer

Type of inspection

Inspection Mode

Alarm

Factory inspection mode

Drum

Ready

Troubleshooting

Troubleshooting

Biuk

Appendix 1. Serial NO. Descriptions

0 0 1 0

Appendix 2. Diameter / Circumference of Rollers

Appendix 3. Print Speeds with Various Settings

Media type setting All models

Media type setting HL-1240 demo model

Print Configuration for HL-1240/1250/1270N only

Appendix 4. HOW to Know Drum Unit Life & page Counter

Fig. A-2

Test Print for HL-1030 only

How to calculate drum unit life

How to Read the Drum Unit Life

How to Read the Page Counter

Fig. A-4

How to Read the Maintenance Information

Fig. A-7

Troubleshooting for Printer won’t print

Appendix 5. HOW to USE the SELF-DIAGNOSTICS Tools

Fig. A-10

Diagnostics

If you click the OK button in , the dialog box below appears

Fig. A-13

Printer Information

Items Descriptions

Appendix 6. Nvram Default Value

Fig. a

Appendix 7. Paper Cassette Information for Europe only

Appendix 8. Connection Diagram, HL-1030/1240

Appendix 9. Connection Diagram, HL-1250

Appendix 10. Connection Diagram, HL-1270N

Appendix 11. Main PCB Circuit Diagram, HL-1030/1240 1/2

Appendix 12. Main PCB Circuit Diagram, HL-1030/1240 2/2

Appendix 13. Main PCB Circuit Diagram, HL-1250/1270N 1/5

Appendix 14. Main PCB Circuit Diagram, HL-1250/1270N 2/5

Appendix 15. Main PCB Circuit Diagram, HL-1250/1270N 3/5

Appendix 16. Main PCB Circuit Diagram, HL-1250/1270N 4/5

Appendix 17. Main PCB Circuit Diagram, HL-1250/1270N 5/5

Appendix 18A. Engine PCB Circuit Diagram OLD

Appendix 18B. Engine PCB Circuit Diagram NEW

Appendix 19. Network Board Circuit Diagram, HL-1270N

Low-voltage PS Circuit 110

Low-voltage PS Circuit 220

High-voltage PS Circuit

CN1 CN2 DEV1

Electrode helical spring / Chute

High-voltage power supply PCB / Engine PCB

Index

Electrical terminal

22,4-30

2-10, 4-4, A-16

1-4

Index

PL-PRN001

Parts Reference List

B48K056 201A

REF.NO Code ’TY Description Symbol Remark

Contents

Main Motor Assy

REF.NO Code QTY Description Symbol Remark

TAPTITE, CUP S M3X6

Solenoid Assy

Frame / Drive Unit

Joint

Bearing

Conductor Bearing

Paper Feeder

Cleaner Spring

Cleaner Roller Assy

REF.NO Code QTY Description Remark

Fixing UNIT, 115V SP

Fixing Unit

Paper Tray ASSY, LGL SP

Paper Indicator

Pressure Plate ASSY, LGL

Pressure Plate Spring

Paper Tray Assy 3 SP

Pressure Roller Holder

Paper Tray ASSY, LEG SP

Paper Cassette

TOP Cover

Rear Cover

10 UL9142001 1 Second Eject Roller Assy

Model Plate

Covers

Main PCB ASSY, HL-1240 SP

Main PCB ASSY, HL-1030 SP

Main PCB ASSY, HL-1240 HEB SP

Main PCB ASSY, HL-1240 PB SP

HL-1030 HL-1240 HL-1250 HL-1270/1270N

Engine PCB Assy A, 1250 SP

Engine PCB Assy A, 1240 SP

LOW-VOLTAGE PS ASSY, 115V SP

LJ8330001 1 Protection Tube

Engine PCB

AC Cord ASSY, SAA

AC CORD, UL/CSA

AC Cord ASSY, SEV

AC CORD, Chli

High Voltage Power Supply PCB

Setup GUIDE, GER

Setup GUIDE, FRA

Setup GUIDE, NL

Setup GUIDE, NOR

Accessories

CARTON, HL-1030 EU

Accessory Carton

CARTON, HL-1030 can

CARTON, HL-1240 US

Packing Materials

Tool no Tool Name Remark

Torx Screw Driver

Molykote PG-662 ADD