SMV

Copyright, Notices, and Trademarks

Copyright 1999 by Honeywell Inc Revision 0 January 18

Conventions and Symbol Definitions

About This Publication

SMV 3000 Transmitter User’s Manual

Table of Contents

103

111

119

137

Figures and Tables

100

Table A-9

Acronyms

Parameters

References

Technical Assistance

Section Contents About This Section

Overview First Time Users Only Introduction

This section includes these topics

Topic

CE Conformity Europe

About Conformity

SMV 3000 Smart Multivariable Transmitters

Meter Body Factory Characterization Data Electronics Housing

Transmitter adjustments

SMV Operating Modes

Smartline Configuration Toolkit SCT

Smartline Configuration Toolkit

Smart Field Communicator SFC

Using the SFC with the SMV

About SFC Communications

Smart Field Communicator SFC

Transmitter Order

Order Components

Smart Field Communicator Model STS103 Operating Guide

Quick Start Reference Introduction

Getting SMV 3000 Transmitter On-Line Quickly

Task Description Reference Section

Preinstallation Considerations Introduction

Electronic pressure transmitters

Considerations for SMV 3000 Transmitter

Evaluate conditions

Operating Temperature Limits

Thermocouple requirements

RTD requirements

Type Rated Range Limits Standard

Considerations for SCT

SCT 3000 Requirements

SMV 3000 Transmitter User’s Manual

Installation Introduction

Mounting SMV 3000 Transmitter

Action If you are using an… Then…

Mounting SMV 3000 Transmitter to a Bracket

Bracket mounting

Step

Step Action

Leveling a Transmitter with a Small Absolute Pressure Span

Flange for manifolds on 2, 2-1/8, or 2-1/4 inch centers

Piping SMV 3000 Transmitter

Pressure lines to the transmitter

Suggested mounting location for the transmitter depends on

Process to be measured. shows the transmitter located above

Drain away from the transmitter

Transmitter location

Piping SMV 3000 Transmitter

General piping guidelines Installing flange adapter

Installing 1/2 inch NPT Flange Adapter

Installing RTD or Thermocouple

Considerations CE Conformity Special Conditions Europe

Wiring SMV 3000 Transmitter

CE Conformity Special Conditions Europe Summary

For the given probe type

Polarity

Refer to .2 CE Conformity Europe Notice for special

Conditions

Optional meter Wiring connections

TPS/TDC 3000 reference

Wiring connections Step

If input is from … Then…

RTD Input Wiring Connections

AWG American Wire Gauge or KCM Kilo Circular Mils bare or

Green covered wire

Optional lightning protection

Ground Connection for Lightning Protection

Conduit seals and Hazardous Location Installations

Getting Started Introduction

Off-line Configuration Procedures SCT Hardware Connections

Off-line Versus On- line SMV Configuration

Establishing Communications

SCT 3000 On-line Connections to

Establishing On-line Communications with the SMV

Making On-line Connections to

Checking Communication Mode Firmware Version

DE Communication Mode

Changing Communication Mode

Making Initial Checks

Write Protect Option

Want to change it

Module for SMV 3000 transmitters

Write Protect Option

SMV 3000 Transmitter User’s Manual

Configuration Introduction

To Print On-line Manual and Help Topics

Changing database parameters configuration

About Configuration

Configuration Summary

Overview

Overview

Using the SCT for SMV 3000 Configuration

Configuring the SMV 3000 with The SCT

SMV Process Variable SCT Template Tab Card

PV1 Priority

Device Configuration

Background Device Data Fields

General Configuration

PV Type Selecting PVs for Broadcast

If You Select PV Type

These PVs are Broadcast to Control System

To represent the output

Background Analog Output Selection

Determine which PV is desired as SMV Output

Then Select…

Line Filter Background

DPConf Configuration PV1

Engineering Units

Engineering Unit

Meaning

LRV and URV PV1 DP Range Values

Output Conformity Background

About Square Root Output

Flow 0utput Full MA dc Scale

About Square Root Output Square Root Dropout

Differential Pressure % Full Scale

Damping Background

AP/GPConf Configuration PV2

Absolute Pressure

STG170

Gauge Pressure

Pressure reading

Flow calculation

PV2 AP/GP or SP Range Values LRV and URV

Selecting PV3 Engineering Units

TempConf Configuration PV3

Engineering Unit Meaning

Cold Junction Compensation Background Output Linearization

Sensor Type Rated Temperature Range Limits

Sensor Type

Fault Detect Background

PV3 Temperature Range Values LRV and URV

Typical RTD Range Configuration

Current Range Settings

Range Settings After LRV is Changed to Zero

Damping Background

FlowConf Configuration PV4

Pre-programmed Mass Flow Engineering Units for PV4

PV4 Engineering

PV4 Flow Upper Range Limit URL Range Values LRV and URV

Lower Range Limit LRL and Upper Range Limit URL identify

About URL and LRL

Typical Volumetric Flow Range Setting Values

LRV and URV set the desired zero and span points for your

About LRV and URV

M3/h

Damping

Low Flow Cutoff for PV4

Graphic Representation of Sample Low Flow Cutoff Action

Using Custom Engineering Units

Using Custom Units for PV4 Flow Measurement

Flow Compensation Wizard

Description Standard Equation

Dynamic Compensation Equation

Primary Element

Dynamic compensation flow equation for mass applications is

Flow = N

Saving, Downloading and Printing a Configuration File

Saving, Downloading Printing a Configuration File

Verifying Flow Configuration

Verify Flow Configuration

Startup Introduction

Startup Tasks

About Startup Step Procedures

BAD PV displayed on TPS/TDC systems

Background Analog Output Mode Procedure

Running Output Check

Procedure Step

Output Check Procedure for SMV Transmitters in DE mode

Output Check for SMV Transmitters in DE Mode

FlowOutCal, for PV4

Using Transmitter to Simulate PV Input

Using SMV Transmitter in Input Mode

APInCal, for PV2

SMV Model SMA125 Start-up Procedure

Procedure

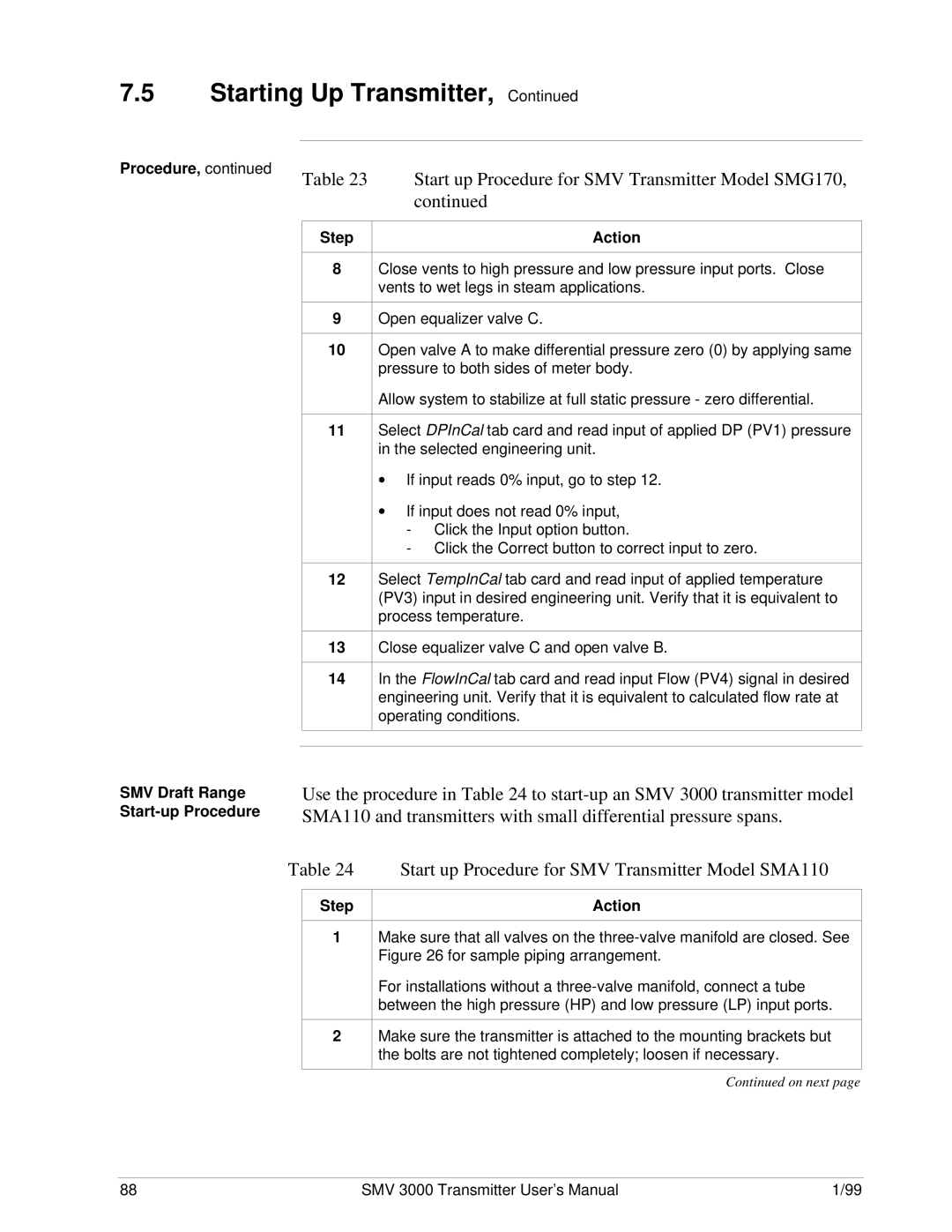

Starting Up Transmitter

Starting Up Transmitter

SMV Draft Range Start-up Procedure

Starting Up Transmitter

SCT

Black

Operation Introduction

Summary Procedure

Accessing Operation Data

If you want to view… Select the SCT

If you want to view…

Select the SCT Window or Tab Card

TempConf

Background Analog and DE Mode Differences

Changing Default Failsafe Direction

Jumper on the main PWA of the electronics module

Cutting Failsafe Jumper

Main PWA

Saving and Restoring SMV Configuration Database

Saving and Restoring a Database

Section Contents

Maintenance Introduction

Topic See

Preventive Maintenance

Maintenance Routines And Schedules

Inspecting and Cleaning Barrier Diaphragms

Background Procedure

22519

Prom number using the SCT See .2 in this manual for details

Replacing Electronics Module or Prom

Plug-in Prom on the main PWA is uniquely characterized to

Required Replacing Electronics Module or Prom

104 SMV 3000 Transmitter User’s Manual

If you are replacing the… Then…

Main PCB If the new electronics module has the write protect

Main PCB

Replacing Meter Body Center Section

Center section is supplied with a new matching Prom

Matching Prom

Replacing Meter Body Center Section

SMV 3000 Transmitter User’s Manual 109

22519

Calibration Introduction

About Calibration

Using the SFC or SCT for Calibration

Test Equipment Required

Calibrating Analog Output Signal

Using the SFC

Calibrating PV1 and PV2 Range Values

Typical PV1 or PV2 Range Calibration Hookup

Resetting Calibration

About Reset Accuracy for PV1 and PV2

118 SMV 3000 Transmitter User’s Manual

Troubleshooting Introduction

Diagnostics Troubleshooting Tools

Troubleshooting Using the SCT

You can clear fault conditions

Diagnostic Messages

Diagnostic Messages Diagnostic Message Table Headings

Critical Status Diagnostic Message Table

Diagnostic Messages

124 SMV 3000 Transmitter User’s Manual

SMV 3000 Transmitter User’s Manual 125

Non-Critical Status Diagnostic Message Table

Status TAG ID.# Corrects RST PV1

SMV 3000 Transmitter User’s Manual 127

128 SMV 3000 Transmitter User’s Manual

SMV 3000 Transmitter User’s Manual 129

130 SMV 3000 Transmitter User’s Manual

Non-Critical Status Diagnostic Message Table

Communication Status Message Table

TAG no Illegal Response URV 3 . TAG ID Invalid Request

SMV 3000 Transmitter User’s Manual 133

Status TAG ID Wire RTD PV3

Informational Status Message Table

SFC Diagnostic Message Table

Page

Parts List Replacement Parts

Part Identification

138 SMV 3000 Transmitter User’s Manual

SMV 3000 Electronics Housing

Key Part Number Description

Quantity Per Unit

Key

Parts Identification for Callouts in Figure

Quantity Per Kit

SMV 3000 Terminal Block Assembly

Key Part Number

SMV 3000 Meter Body

Description Quantity Per Unit

Quantity Per Unit Flange Adapter Kits two heads

K10 K11

Process Head Kits one head with Viton head gasket

K10 K13

Part Number Description Reference

Summary of Recommended Spare Parts

Spares for

Wiring Diagrams

SMV Multivariable Transmitter Wiring Diagrams for

Using Mounting Bracket Type

See Drawing Number

148 SMV 3000 Transmitter User’s Manual

Appendix Contents

Appendix a PM/APM/HPM SMV 3000 Integration Overview

This appendix includes these topics

Purpose of this appendix

Description

Definition Communications Link Compatibility

DE/ Digital

Diagram Typical Integration Hierarchy

SMV3000 Transmitter

Data Exchange Functions

Exchange of data over the bi-directional data path between

SMV 3000 transmitter and the PM/APM/HPM is based on imaging

Stimv IOP for each transmitter PV. This is done by mapping

Points per Stimv IOP

SMV 3000 Transmitters

Figure A-4 AI Point for Each Transmitter Input

Four Points Per Transmitter

Broadcast using the SCT

Application. Table A-1 shows what PVs represent in the SMV

See Deconf parameter in subsection A.5 and Deconf Changes

SMV PV Number

About Database Broadcast

Installation

Other Smartline transmitter. See in the PM/APM Smartline

Mounting Assumptions

Connection Rule

Figure A-5 Connection Rule Example

Configuration

About Configuration Getting Started

Building Points

Point Building Rules

PED Entries

Eudesc Parameter

If Process Variable Number is…

Then base engineering unit is …

Listed in Table A-5

Table A-5 PV Characterization Selections for SMV 3000 PVs

So the value is the same regardless of EU

Mind, that the URL, LRL, URV, and LRV are displayed in base

URL Parameter

If PED Deconf entry is …

Then URL is …

If Process Variable Number is… PV1 or PV2

Then Damping Value can be …

Piuotdcf Parameter Cjtact Parameter

After Point is Built

Generic Operations Detail Display Difference

Operation Notes

Database Mismatch Parameters

Figure A-7 Example of Deconf Download Error Message

Deconf Changes

Table A-10 Conversion Values for PV3 Temperature

Conversion Multiplier

Engineering Unit Conversion for PV4

Conversion Offset

Table A-12 Conversion Values for PV4 as Mass Flow Rate

Conversion Offset Secondary Variable Reference

Problem

Status Messages

Message

Corrective Action

170 SMV 3000 Transmitter User’s Manual

Appendix B SMV 3000 Configuration Record Sheet

Appendix B- Configuration Record Sheet

1b. Static Pressure PV2 Configuration Section

SMV 3000 Transmitter User’s Manual 173

174 SMV 3000 Transmitter User’s Manual

Appendix C -PV4 Flow Variable Equations Overview

Reference Data Sources

Standard Flow Equation

Example Air Through a Venturi

178 SMV 3000 Transmitter User’s Manual

Example Superheated Steam Using an Averaging Pitot Tube

Standard Flow Equation

Dynamic Compensation Flow Equation

Table C-3 Liquid Propane Configuration Example

SMV 3000 Transmitter User’s Manual 183

184 SMV 3000 Transmitter User’s Manual

Table C-4 Air Configuration Example

Example Air

186 SMV 3000 Transmitter User’s Manual

SMV 3000 Transmitter User’s Manual 187

SMV Operation in a Steam Application

Example Superheated Steam

Table C-5 Superheated Steam Configuration Example

190 SMV 3000 Transmitter User’s Manual

Dynamic Compensation Flow Equation

Page

SMV 3000 Smart Multivariable Transmitter

# in User Sub-Section Description of Change

Torque Table Process Head Bolts/Nuts

································

···································

34-SM-99-01 Addendum to 33-SM-25-02 03/04

Psi

03/04 34-SM-99-01 Addendum to 33-SM-25-02

Index

Cont’d

194 SMV 3000 Transmitter User’s Manual

SMV 3000 Transmitter User’s Manual 195

Industrial Automation and Control