GL4xxe Operator’s Manual

Version SI-GL4xxe-01rB-11-11-OM

Worldwide Contact Details

Table of Contents

Buffer Clear

Printer Configuration

Maintenance

Troubleshooting

Introduction

Personal Injury

About this Manual

Primary Components

General Description

LCD Display

Control Features

Technical Data

Power

Physical Characteristics

Command

Environmental

Media

Sensing

Ribbon

Regulatory

Character Font Capabilities

Barcode Capabilties

Installation

Unpacking & Parts Identification

Unpacking & Parts Identification

Site Location

Printer Installation

Cable Connection

Media & Ribbon Loading

Media Selection

3b, Fan-fold Media Loading

Operational Mode Selection

Label Print Direction

Interface Selection

Interface Specifications

RS232C HIGH-SPEED Serial Interface

Signal Signal Definition

READY/BUSY Interface Signals

READY/BUSY Cable Requirements DB9 Host Direction Printer

PIN Assignments Signal Direction

Specifications

IEEE1284 Parallel Interface

Universal Serial BUS USB

Software Specifications

Local Area Network LAN Ethernet

LED Indicator Status

802.11G Wireless

Network Port Link LED Off To 50% weak

Wireless LAN Signal Strength

50 to 75% medium

75 to 100% strong

ALL Interfaces

Interface Signals

Cable Requirements DB9 Host Direction Printer

Receive Buffer Control

Unit 3 Installation

Unit 3 Installation

Output

External Signal

Print Start Prin Input

+24V +5V

+5V +24V

High high impedance, Low -15mA or more

Reprinting

Input Signal Wave Form Start Printing

Machine Error

Output Signal Wave Form Basic Operation

Paper END

Ribbon END

14, Operation Mode Flow Chart

Interface Installation

Accessories Installation

Flash Memory Card

Printer Configuration

Printer Configuration

User Mode

Configuration Modes

Line

Configuration Mode

Function

Advanced Mode

3b, Advanced Mode

Enter

Serial Interface Mode

Parallel Interface Mode

Parallel Interface Mode

Centronics Interface Mode

Centronics Interface Mode

USB Interface Mode

Universal Serial BUS USB Interface Mode

Interface Mode

Local Area Network LAN Interface Mode

Wlan Address

Wireless Local Area Network Wlan Interface Mode

Emulation

PGL Emulation Mode

ZGL

ZGL Emulation Mode

DGL

DGL Emulation Mode

TGL

TGL Emulation Mode

IGL

IGL Emulation Mode

15, Diagnostics Mode

Diagnostics Mode

16, Printer Management Mode

Printer Management Mode

Misc Quick Menus

Display Intensity Adjustment

Buffer Clear

KEY LOCK/UNLOCK

Soft Reset

Menu Definition Tables

User Mode Table Menu

Menu Description

User Mode Table

Adjusted by this menu between -100and +100

No Change factory default

Presented in the UPC/EAN barcodes

Readable data is not present

Enable is the factory default

Enable Will reprint a label affected by an error condition

Activity

Automatic always the same as the print speed

Configuration Mode Table

Powered off

Is the menu selection screen for the Configuration Mode

Exisitng configuration has first been deleted

Factory default is

Factory default is Current

Is a sub-menu of the configuration print feature

Disable factory default. Will overwrite

Enable will not overwrite

Advanced Mode Table

Menu options

Assembly installed

Permits selection of the media handling method desired

Label over the tear bar for removal

Current configuration menu

Leading edge of the eye-mark indicator black mark

Handling method

But only supports label lengths 2.50 inches or longer

Permits entry into the Power Saver TIme sub-menus

Each label. The factory default is Print Profile

Disable the power saver feature will not function

Factory default is English

Enable or disable. Disable is the factory default

Serial is the factory default

PPI/ZGL to send the status back to the host

To/from flash memory or Ram

Is the sub-menu of the Auto Locking feature

Auto Locking sub-menu to be enabled or disabled as desired

Extended Memory Card Flash File System

Being overwritten by disabling the overwrite function

Again. Press the Function key to exit the Advanced Mode

Is the sub-menu of the Set Lock Key feature

Range is 0 to 512, and the factory default is

Is 0 to 512, and the factory default is

Enable increases the point height by approximately 10%

512, and the factory default is

Allowable range is 0 to 20, the factory default is

Continually display

Factory default is 75 for eye-mark sensing

Factory default is 171 with a range of 000 to

Factory default is 150 for eye-mark sensing

Within the current configuration menu

Factory default is 0.12 inches

After a Printhead Open fault

Peel-Off Media Handling mode

Printer will not perform calibration at power up

Serial Interface Mode Table

No factory default. Will not be deleted

Is the menu selection screen for the Interfaces Mode

Deleted when the printer’s power is turned off

Deleted

Follow

Factory default is None

Computer. The options are Odd, Even, Mark, Sense, or None

Kbytes in 1 kbyte increments

Transmission

False never asserts the DTR signal

True factory default. Continuaously asserts the DTR signal

On-Line- asserts the RTS signal when the printer is online

False never asserts the RTS signal

Parallel Interface Mode Table

Not recommended

For Bi-Com interface

Into the applicable menus

Will follow

Disable the option

Disable is not used

To 16 Kbytes in 1 kbyte increments

Busy for too long

Printer is offline until the printer’s buffer is full

Centronics Interface Mode Table

Menus will follow

Signal is true

Which interpret the 8th data bit line as a PI signal

Option

Codes

Universal Serial BUS USB Interface Mode Table

Universal Serial BUS USB Interface Mode Table

Local Area Network LAN Interface Mode Table

Local Area Network LAN Interface Mode Table

Display menu item Timeout

Disable will not recognize

Enable factory default. Will recognize

Match the host computer setting

Allowable range is 0 to 65535, and the factory default is

Defaults for the SEG1 through SEG4 are 000, 000, 000,

Factory defaults for SEG1 through SEG4 are 000, 000, 000,

Factory default is Disable

Read only

Ethernet Port Ethernet Setting Wlan Address Wlan Setting

Ethernet

Initialization, the LCD displays E-NET Ready

Cannot be changed

Dynamic and read only

Auto-negociate- factory default. Automatically selects

These characters may be alphanumeric, symbols, or spaces

Access Point in infrastructure mode

Idenitification entered into the menu screen that follows

PGL Emulation Mode Table

Will contain a list of emulation options available

Is the menu selection screen for the Emulation Mode

Intermec, Sgpl for SATO, and DGL for Datamax

This menu selects the character set used by the printer

Disable factory default. Will print in upper and lowercase

Command

Enable will print text only in uppercase

Enable zero will be printed with a slash

Create command plus the Var Form Adjust menu

Form Adjust

Add Nothing factory default. No action is taken

Disable factory default. Use standard barcode ratios

Allowable range is 0 to 255, and the default is

Feature is initialized in the Normal mode

Enabled

Allowable range is 0 to 255 in decimal, and the default is

Disable factory default. No effect

Normal factory default. Normal scaling

Disable uses the current method of decoding

Disable replaces the user-defined ratio

Cancel select Stcc Cancel command

Factory default is 0 dots

Report

Graphic elements and the height of the vertical line

Allows selection of control instructions command prefix

ZPL-II- factory default. Zebra Programming Language

This menu allows compatibility selection to ZPL-I or ZPL-II

ZPL-I- Zebra Programming Language

ZGL Emulation Mode Table

Setup or Media Control menu

Determines the method of setting the Label Length

Selects the current setting associated wit the JM command

Media Control menu

DGL Emulation Mode Table

Enable feedback characters are sent to the host

Is the menu selection screen for the Emualtion Mode

Underlying emulation

Characters sent from the host system

To this setting after the current label format is finished

Imperial factory default. American Standard values

Can be fine adjusted by this menu

Allowable range is -100to +100, with a factory default

TGL Emulation Mode Table

Enable the zero character is overlayed with a slash

Determines where and how errors will be displayed

Ignored

No all data is is passed to the LP+ emulation

TGL Emulation Mode Table Menu

IGL Emulation Mode Table

Advanced 5mil factory default. Standard for 203 dpi

Allows the selection of the printer’s print resolution

Head is installed, the mode will always be Advanced 3.3mil

Factory default is US Ascii

IGL Emulation Mode Table Menu

Calculations can be fine adjusted

Override operator panel settings

Allowable range is -100to +100 with a factory default

Resolution of the printer running IGL

Is the menu selection screen for the Diagnostics Mode

Permits entry into the Diagnostics Mode

Used for printing. The LCD will reflect the new setting

Incoming print job regardless of different command settings

Diagnostics Mode Table Menu

This value is set to zero at the factory following testing

Diagnostics Mode Table

Following testing

Dist, Head On Time to zero

Is the menu selection screen for the Printer Management Mode

Printer Management Mode Table

Options are Pxml or UCP, and the factory default is UCP

Disable factory default. Not activated

Via Ethernet or Serial

Serial connects to serial port

Disable factory default. Is not active

This menu disables the serial port

Enable is active

Power-up. Resets the modem configuration to

Quick Menus Tables 4-17 Through

Troubleshooting

Display Explanation Solution

Error Signal Troubleshooting

Delete and optimize files

Printer encountered an error trying to

Reboot the printer

Mem Adjust size in the Printer Setup menu

Flash memory

Engine control software failure

Rotates Problem writing to flash memory

Different fault message will apear

Setup menu

Enter the Printer Setup menu and use

If using media without gaps or eye-marks

To detect the installed media

Installed. These modes require that the front

Door assembly be installed to use the Label

Moves forward to the next top-of-form position

Cicuit board Customer service representative

Protocol, Baud Rate, Data Bits, Stop Bits, Parity

Data Terminal Ready, and Request To Send

Troubleshooting Table

Printer Creates a Blank Label

No Printed Image

Incorrect Label Positioning

Smeared Print Images

CHK Troubleshooting Step

Interface Troubleshooting

Ensure the wireless card is properly installed

Ensure the antenna is properly and completely installed

Seconds for a print out of configurations

Manufacturer’s documentation for details

HEX Dump

Test Print Troubleshooting

Test Label Printing

Sample Test Label

Maintenance

Cleaning Procedures

Print Head Replacement

Replacement Procedures

Fuse Replacement

Fuse Replacement

Media Platen Roller Replacement

Media Platen Roller Replacement

Label Sensor Positioning

Adjustment Procedures

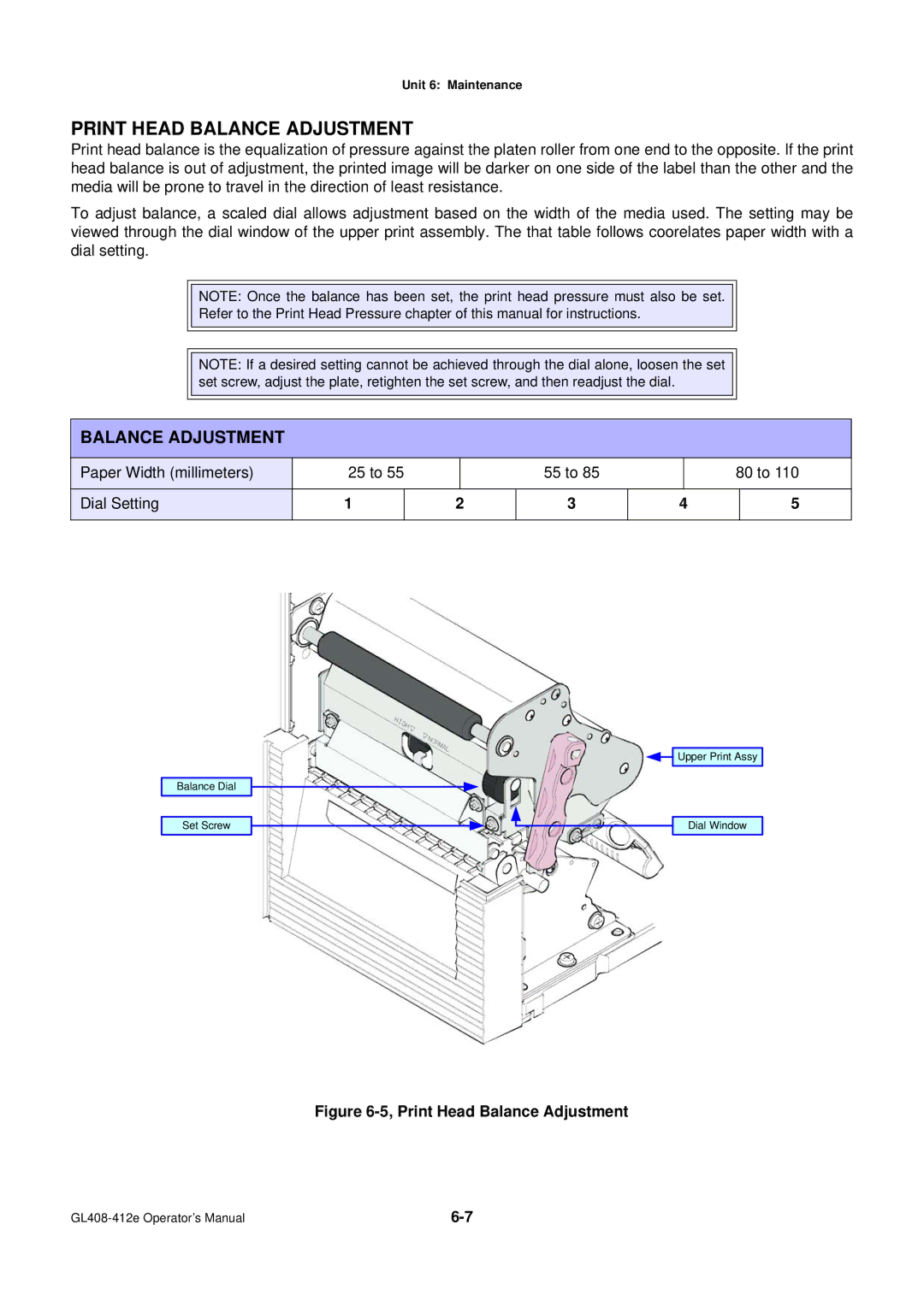

Balance Adjustment

Print Head Balance Adjustment

Print Head Pressure

Balance Adjustment Media Scale Thickness

Print Head Alignment

Print Head Alignment

Head Balance and Print Head Alignment

Ribbon Guide Alignment

Ribbon Roller Alignment

Ribbon Roller Alignment

![]()

![]() Upper Print Assy

Upper Print Assy