Model SB1016/SB1036 | O P E R A T I O N | For Machines Mfg. Since 7/09 |

Faceplate

Refer to Chuck & Faceplate Mounting instructions on Page 35 to mount the faceplate to the spindle.

The 15" faceplate included with your lathe offers a wide range of uses, including machining non- concentric workpieces, straight turning between centers,

The tools needed for mounting a workpiece will vary depending on the type of setup you have.

Failure to properly secure a workpiece to the faceplate could cause the workpiece to be thrown from the lathe with deadly force at the operator or bystanders. Use a minimum of three independent clamping devices to hold a

Machining

Mounting Workpiece with Clamps

1.DISCONNECT LATHE FROM POWER!

2.Place a piece of 3⁄4" plywood on the bedway below the spindle.

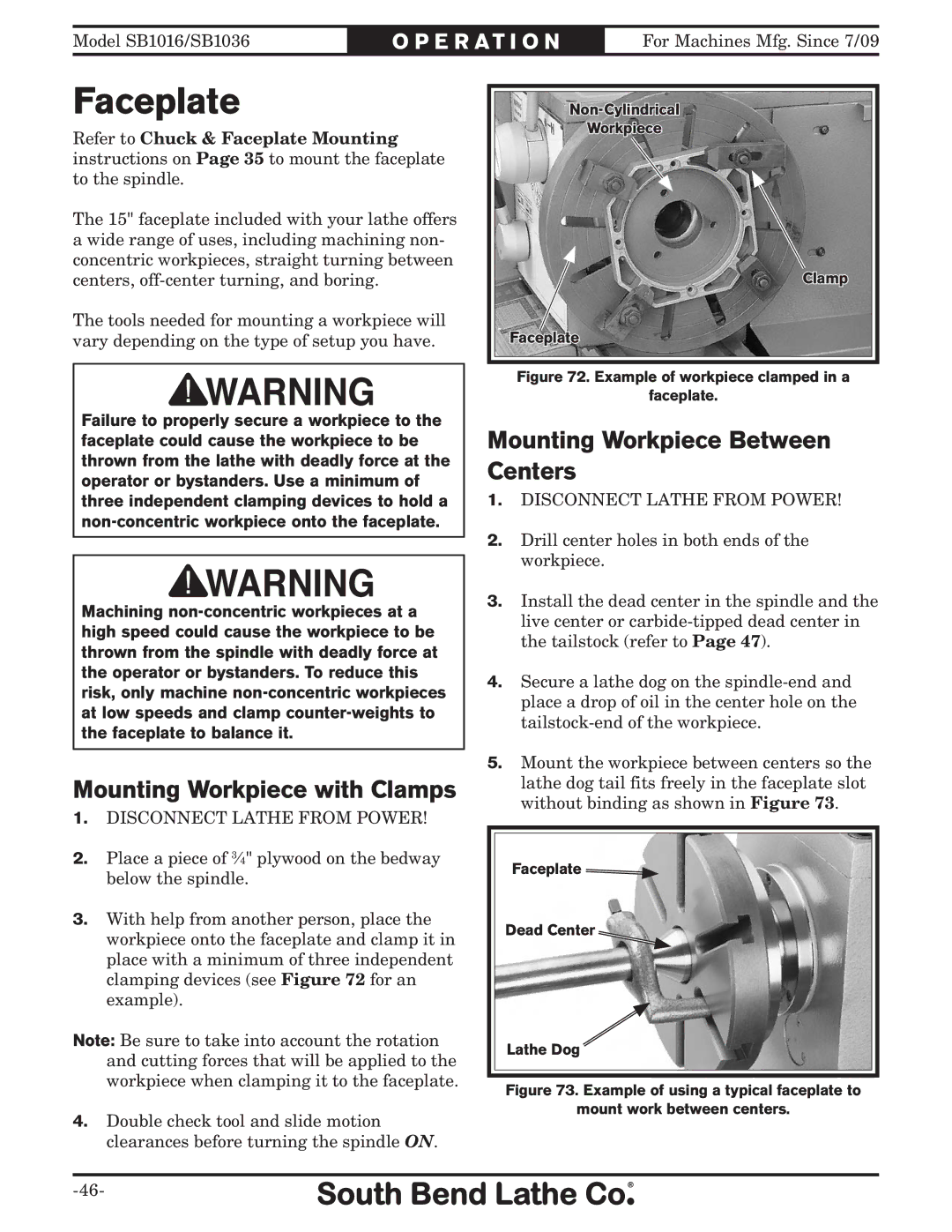

3.With help from another person, place the workpiece onto the faceplate and clamp it in place with a minimum of three independent clamping devices (see Figure 72 for an example).

Note: Be sure to take into account the rotation and cutting forces that will be applied to the workpiece when clamping it to the faceplate.

4.Double check tool and slide motion clearances before turning the spindle ON.

Workpiece

Clamp

F![]()

![]() aceplate

aceplate

Figure 72. Example of workpiece clamped in a

faceplate.

Mounting Workpiece Between Centers

1.DISCONNECT LATHE FROM POWER!

2.Drill center holes in both ends of the workpiece.

3.Install the dead center in the spindle and the live center or

4.Secure a lathe dog on the

5.Mount the workpiece between centers so the lathe dog tail fits freely in the faceplate slot without binding as shown in Figure 73.

F![]()

![]() aceplate

aceplate ![]()

Dead Center

L![]()

![]() athe Dog

athe Dog