Model SB1016/SB1036 | O P E R A T I O N | For Machines Mfg. Since 7/09 |

Repositioning Change Gears

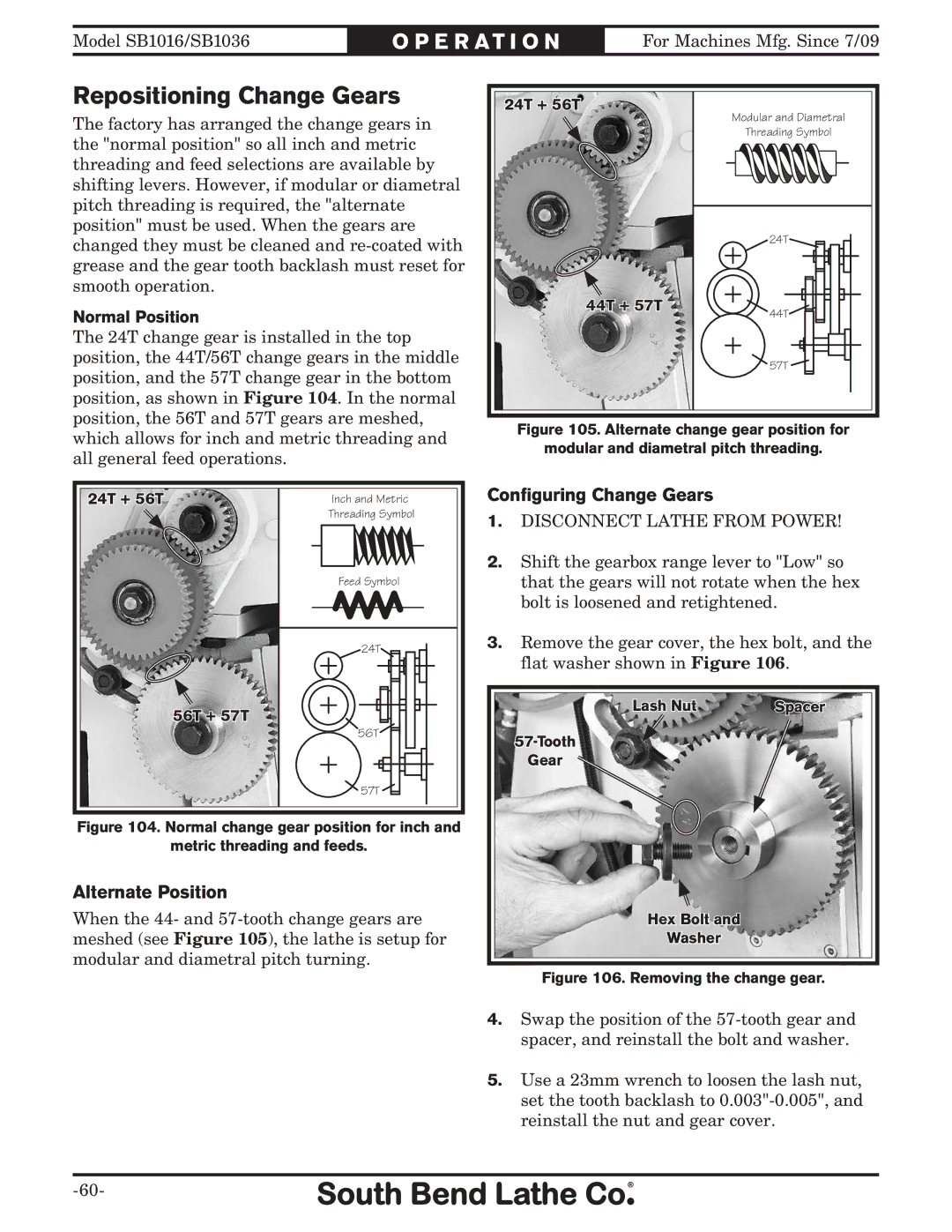

The factory has arranged the change gears in the "normal position" so all inch and metric threading and feed selections are available by shifting levers. However, if modular or diametral pitch threading is required, the "alternate position" must be used. When the gears are changed they must be cleaned and

Normal Position

The 24T change gear is installed in the top position, the 44T/56T change gears in the middle position, and the 57T change gear in the bottom position, as shown in Figure 104. In the normal position, the 56T and 57T gears are meshed, which allows for inch and metric threading and all general feed operations.

24T + 56T | Inch and Metric |

| Threading Symbol |

| Feed Symbol |

| 24T |

| 56T + 57T |

| 56T |

| 57T |

Figure 104. Normal change gear position for inch and

metric threading and feeds.

Alternate Position

When the 44- and

24T + 56T | Modular and Diametral |

| |

| Threading Symbol |

| 24T |

44T + 57T | 44T |

| |

| 57T |

Figure 105. Alternate change gear position for

modular and diametral pitch threading.

Configuring Change Gears

1.DISCONNECT LATHE FROM POWER!

2.Shift the gearbox range lever to "Low" so that the gears will not rotate when the hex bolt is loosened and retightened.

3.Remove the gear cover, the hex bolt, and the flat washer shown in Figure 106.

Lash Nut | Spacer |

Gear

Hex Bolt and

Washer

Figure 106. Removing the change gear.

4.Swap the position of the

5.Use a 23mm wrench to loosen the lash nut, set the tooth backlash to