For Machines Mfg. Since 7/09 | S E R V I C E | Model SB1016/SB1036 |

5.Place sheet of wood on the ways to protect them when the chuck is removed.

6.Using the appropriate lifting apparatus, remove the chuck as shown in Figure 148.

Brake

Linkage

Cover

Figure 148. Removing the 3-jaw chuck from a spindle

nose.

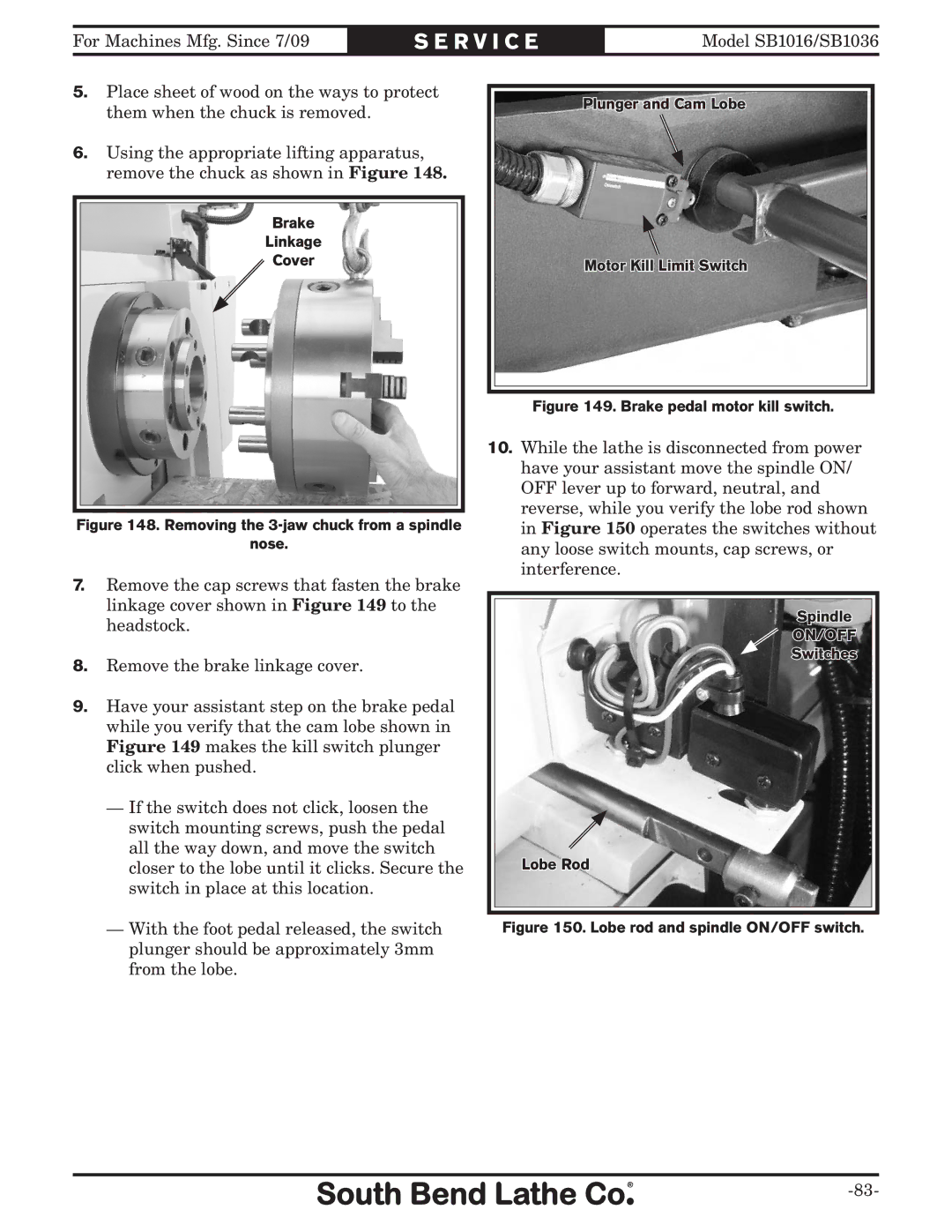

7.Remove the cap screws that fasten the brake linkage cover shown in Figure 149 to the headstock.

8.Remove the brake linkage cover.

9.Have your assistant step on the brake pedal while you verify that the cam lobe shown in Figure 149 makes the kill switch plunger click when pushed.

—If the switch does not click, loosen the switch mounting screws, push the pedal all the way down, and move the switch closer to the lobe until it clicks. Secure the switch in place at this location.

—With the foot pedal released, the switch plunger should be approximately 3mm from the lobe.

Plunger and Cam Lobe

Motor Kill Limit Switch

Figure 149. Brake pedal motor kill switch.

10.While the lathe is disconnected from power have your assistant move the spindle ON/ OFF lever up to forward, neutral, and reverse, while you verify the lobe rod shown in Figure 150 operates the switches without any loose switch mounts, cap screws, or interference.

Spindle

ON/OFF

Switches

Lobe Rod