Model SB1016/SB1036 | M A I N T E N A N C E | For Machines Mfg. Since 7/09 |

Apron

Oil Type | Mobil Vactra 2 or ISO 68 Equivalent | |

Oil Amount | As Needed | |

Check/Add Frequency | .................................... Daily | |

Change Frequency | Annually | |

Checking & Adding Oil

The sight glass shown in Figure 124 shows the oil level in the apron. At the full level, the oil fills approximately 3⁄4 of the sight glass. At the add level, the oil fills 1⁄4 of the sight glass or less. Check the oil level daily and after using the apron oil pump.

Sight Glass

Drain Plug

Figure 124. Location of apron drain plug & sight glass.

Changing Oil

The oil in the apron reservoir must be changed after the

Fill![]()

![]() Plug

Plug

Figure 125. Location of fill plug for apron oil reservoir.

Lead Screw

Oil Type ...... Mobil Vactra 2 or ISO 68 Equivalent

Oil Amount | As Needed |

Lubrication Frequency | Daily |

Before lubricating the leadscrew, clean it first with mineral spirits. A paint brush works well to help clean out the threads. Make sure to move the carriage out of the way, so you can clean the entire length of the leadscrew.

Apply a thin coat of oil along the length of the leadscrew. Use a paint brush to make sure the oil is evenly applied and down in the threads.

Ways & Slides

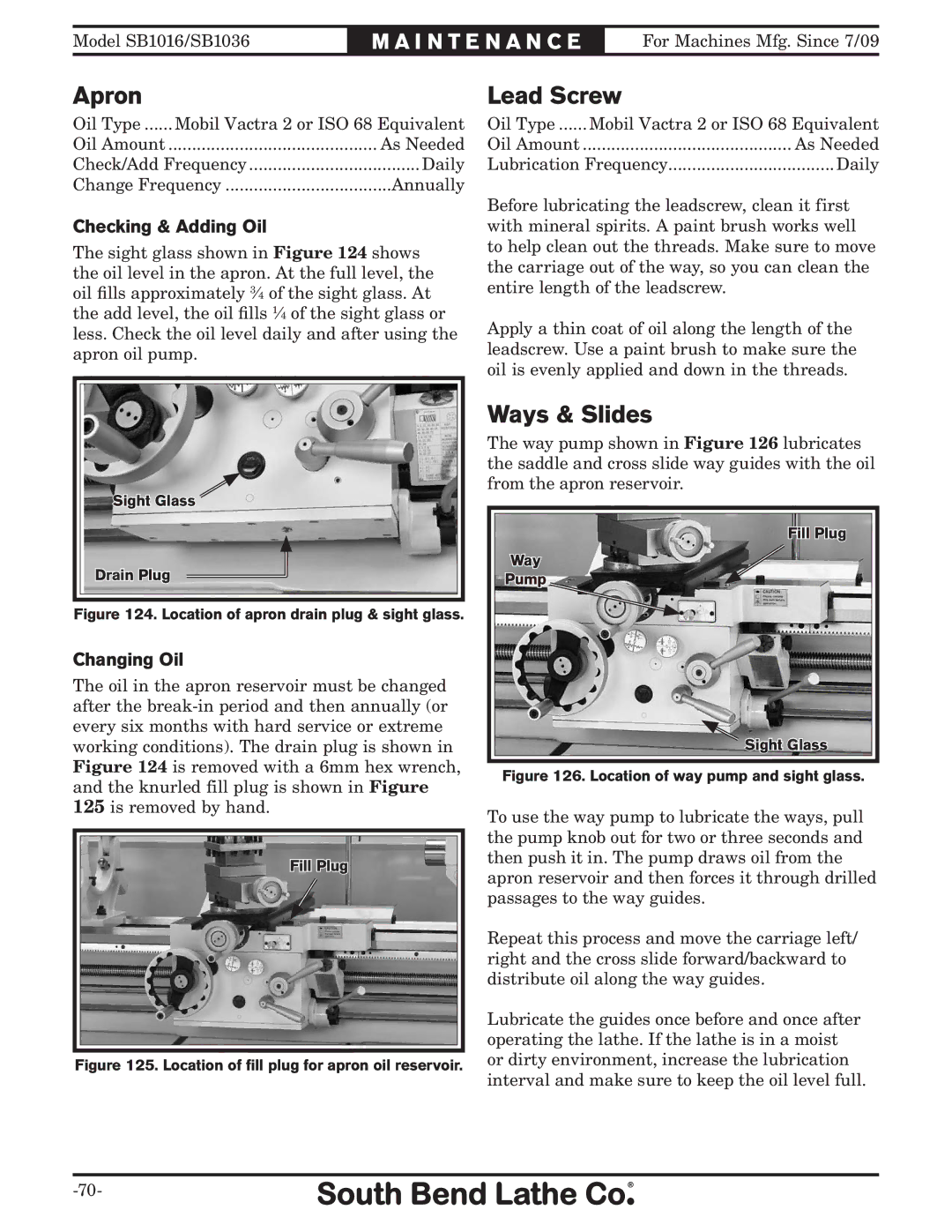

The way pump shown in Figure 126 lubricates the saddle and cross slide way guides with the oil from the apron reservoir.

Fill Plug |

Way |

Pump |

Sight Glass |

Figure 126. Location of way pump and sight glass.

To use the way pump to lubricate the ways, pull the pump knob out for two or three seconds and then push it in. The pump draws oil from the apron reservoir and then forces it through drilled passages to the way guides.

Repeat this process and move the carriage left/ right and the cross slide forward/backward to distribute oil along the way guides.

Lubricate the guides once before and once after operating the lathe. If the lathe is in a moist or dirty environment, increase the lubrication interval and make sure to keep the oil level full.