Model SB1016/SB1036 | S E R V I C E | For Machines Mfg. Since 7/09 |

Tailstock Gib

When the tailstock is offset, it slides along a dovetailed way that has a gib installed between the upper and lower tailstock halves. To maintain alignment and prevent the upper portion of the tailstock from tilting

Tools Needed: | Qty |

Standard Screwdriver #3 | ...................................... 1 |

Wrench 28mm | 1 |

To adjust the tailstock gib:

1.Loosen the front and rear lock bolts (see Figure 143), and unlock the tailstock from the bed.

Half Nut Adjustment

The half nut mechanism can be tightened if it becomes loose from wear. The pressure exerted by the half nut is controlled by a gib. The half nut gib is adjusted with two set screws.

Tool Needed: | Qty |

Hex Wrench 3mm | ................................................. 1 |

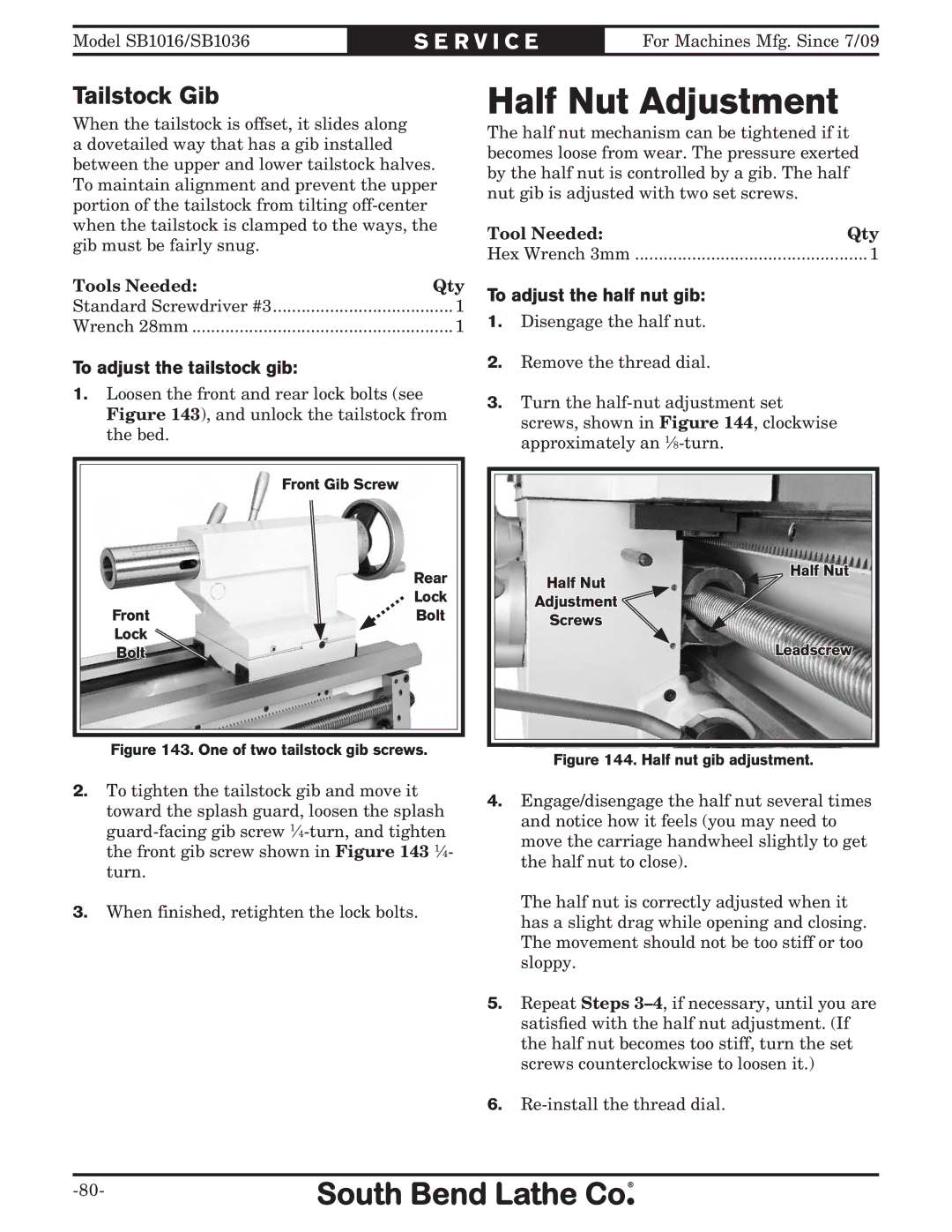

To adjust the half nut gib:

1.Disengage the half nut.

2.Remove the thread dial.

3.Turn the

Front Gib Screw

Rear

Lock

FrontBolt Lock

Bolt

Figure 143. One of two tailstock gib screws.

Half Nut

Half Nut

Adjustment

Screws

Leadscrew

Figure 144. Half nut gib adjustment.

2.To tighten the tailstock gib and move it toward the splash guard, loosen the splash

3.When finished, retighten the lock bolts.

4.Engage/disengage the half nut several times and notice how it feels (you may need to move the carriage handwheel slightly to get the half nut to close).

The half nut is correctly adjusted when it has a slight drag while opening and closing. The movement should not be too stiff or too sloppy.

5.Repeat Steps

6.