Model SB1016/SB1036 | O P E R A T I O N | For Machines Mfg. Since 7/09 |

Offsetting

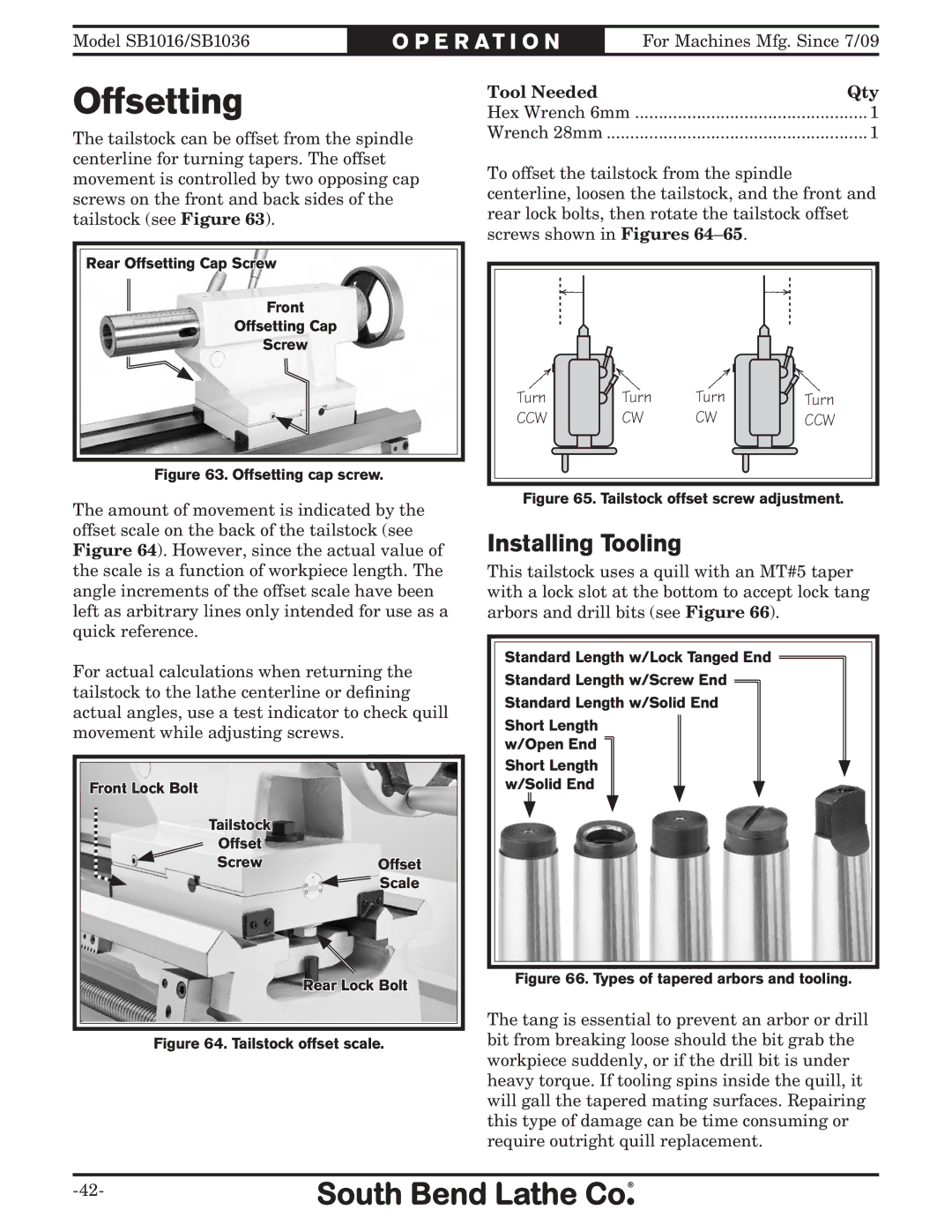

The tailstock can be offset from the spindle centerline for turning tapers. The offset movement is controlled by two opposing cap screws on the front and back sides of the tailstock (see Figure 63).

Rear Offsetting Cap Screw

Front

Offsetting Cap

Screw

Figure 63. Offsetting cap screw.

The amount of movement is indicated by the offset scale on the back of the tailstock (see Figure 64). However, since the actual value of the scale is a function of workpiece length. The angle increments of the offset scale have been left as arbitrary lines only intended for use as a quick reference.

For actual calculations when returning the tailstock to the lathe centerline or defining actual angles, use a test indicator to check quill movement while adjusting screws.

Front Lock Bolt |

|

Tailstock |

|

Offset |

|

Screw | Offset |

| Scale |

Rear Lock Bolt

Figure 64. Tailstock offset scale.

Tool Needed | Qty |

Hex Wrench 6mm | ................................................. 1 |

Wrench 28mm | 1 |

To offset the tailstock from the spindle centerline, loosen the tailstock, and the front and rear lock bolts, then rotate the tailstock offset screws shown in Figures

Turn | Turn | Turn | Turn |

CCW | CW | CW | CCW |

Figure 65. Tailstock offset screw adjustment.

Installing Tooling

This tailstock uses a quill with an MT#5 taper with a lock slot at the bottom to accept lock tang arbors and drill bits (see Figure 66).

Standard Length w/Lock Tanged End |

Standard Length w/Screw End |

Standard Length w/Solid End |

Short Length |

w/Open End |

Short Length |

w/Solid End |

Figure 66. Types of tapered arbors and tooling.

The tang is essential to prevent an arbor or drill bit from breaking loose should the bit grab the workpiece suddenly, or if the drill bit is under heavy torque. If tooling spins inside the quill, it will gall the tapered mating surfaces. Repairing this type of damage can be time consuming or require outright quill replacement.