For Machines Mfg. Since 7/09 | O P E R A T I O N | Model SB1016/SB1036 |

Setting Spindle Speed

Make sure the variable speed dial is turned all the way to the left (counterclockwise) before turning the lathe ON, or the spindle may start up at a dangerously high rate of speed.

1.Make sure the spindle is turned OFF and it has come to a complete stop.

2.Use the chart in Figure 85 to determine the available spindle speed range closest to your calculated spindle speed.

SPINDLE SPEED RANGES |

| RPM | |

Low Speed Range 1 |

|

| |

|

| ||

|

|

|

|

Medium Speed Range 2 |

|

| |

|

| ||

High Speed Range 4 |

|

| |

|

|

|

|

Figure 85. Spindle speed range chart.

3.Turn the spindle speed dial shown in Figure 86 all the way counterclockwise to the minimum.

Spindle Speed Spindle Speed Dial

RPM Display

Figure 86. EVS spindle speed controls.

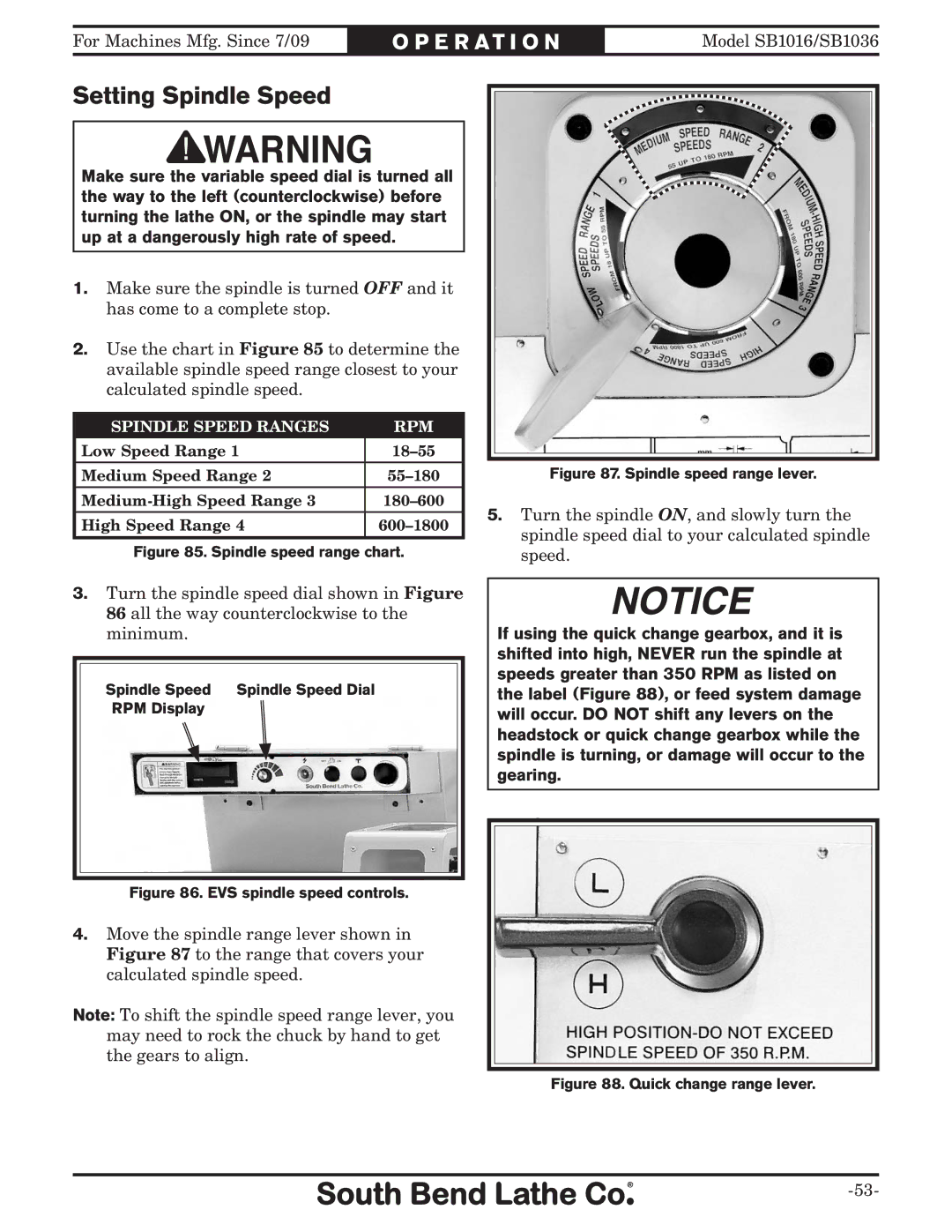

4.Move the spindle range lever shown in Figure 87 to the range that covers your calculated spindle speed.

Note: To shift the spindle speed range lever, you may need to rock the chuck by hand to get the gears to align.

Figure 87. Spindle speed range lever.

5.Turn the spindle ON, and slowly turn the spindle speed dial to your calculated spindle speed.

If using the quick change gearbox, and it is shifted into high, NEVER run the spindle at speeds greater than 350 RPM as listed on the label (Figure 88), or feed system damage will occur. DO NOT shift any levers on the headstock or quick change gearbox while the spindle is turning, or damage will occur to the gearing.