For Machines Mfg. Since 7/09 | S E R V I C E | Model SB1016/SB1036 |

V-Belts

Tools Needed: | Qty |

Phillips Screwdriver #2 | 1 |

Open End Wrench 24mm | 1 |

To adjust the V-belts:

1.DISCONNECT LATHE FROM POWER!

2.Remove the cover shown in Figure 145.

Motor Mount

Bolt

Figure 145. Location of belt tension adjustment.

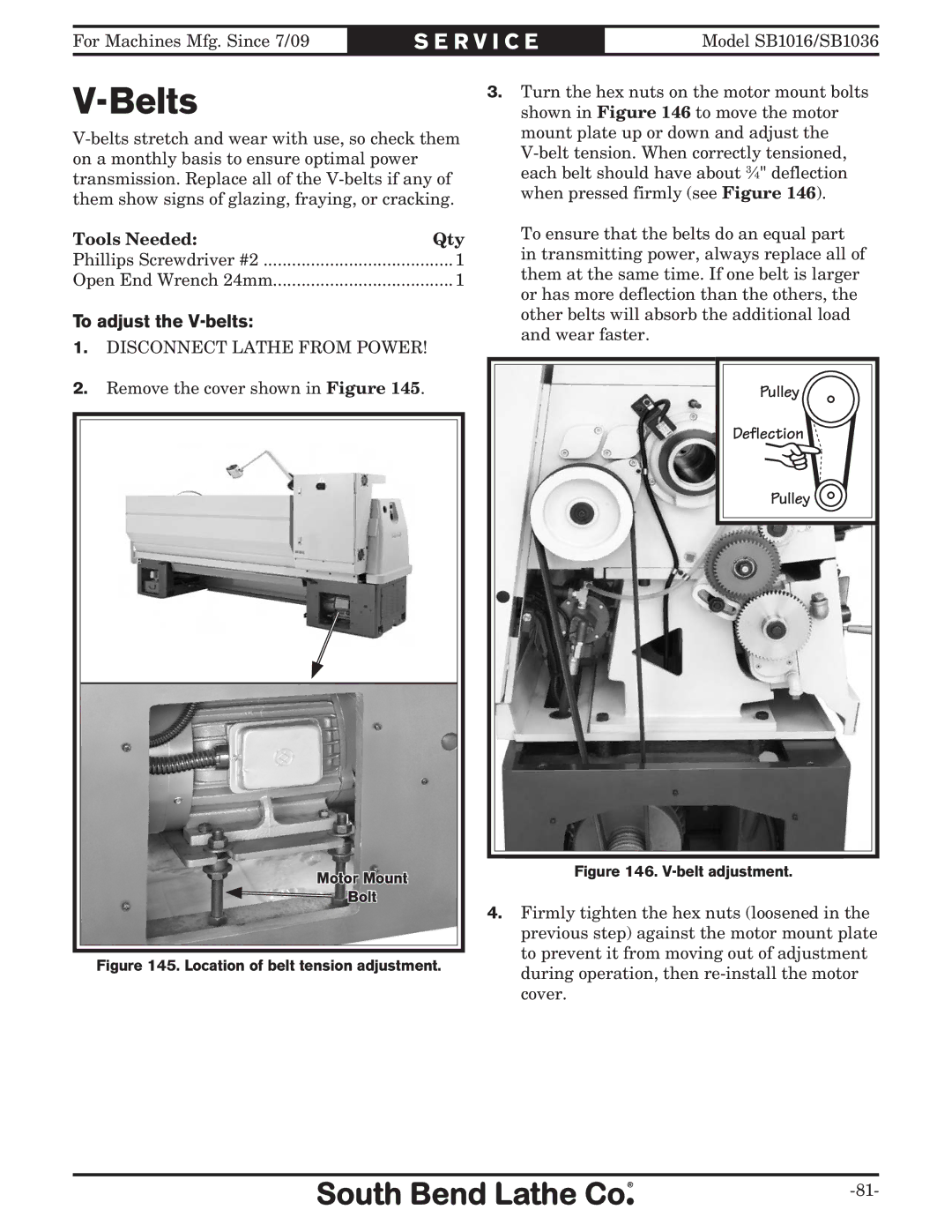

3.Turn the hex nuts on the motor mount bolts shown in Figure 146 to move the motor mount plate up or down and adjust the

To ensure that the belts do an equal part in transmitting power, always replace all of them at the same time. If one belt is larger or has more deflection than the others, the other belts will absorb the additional load and wear faster.

Pulley |

Deflection |

Pulley |

Figure 146. V-belt adjustment.

4.Firmly tighten the hex nuts (loosened in the previous step) against the motor mount plate to prevent it from moving out of adjustment during operation, then