For Machines Mfg. Since 7/09 | M A I N T E N A N C E | Model SB1016/SB1036 |

Unpainted & Machined Surfaces

Besides the ways and leadscrew, all other unpainted and machined surfaces should be wiped down daily to keep them

is necessary for protection. Any quality metal protectant can be used to protect machined surfaces, including either of the oils you use elsewhere in the lathe.

Ball Oilers

Oil Type | Mobil Vactra 2 or ISO 68 Equivalent | ||

Oil Amount | As required | ||

Pump Oil Can w/Plastic or Rubber Cone Tip | 1 | ||

Lubrication Frequency | Before and After Use | ||

Proper lubrication of ball oilers is done with a

Lubricate the ball oilers before and after use machine use, and more frequently under heavy use. When lubricating ball oilers, clean the outside surface to remove any dust or grime. Push the rubber or plastic tip of the oil can nozzle against the ball oiler to create a hydraulic seal, and pump the oil can once or twice. If sludge and contaminants are seen being pushed out of the lubrication area, keep pumping the oil gun until clean oil is seen. When finished, wipe away the contaminants and oil.

Never blow out ball oilers or oil galleys with an air gun to purge the system of contaminants. Air pressure can force contaminants into unreachable areas and dislodge seals and blow- out gaskets.

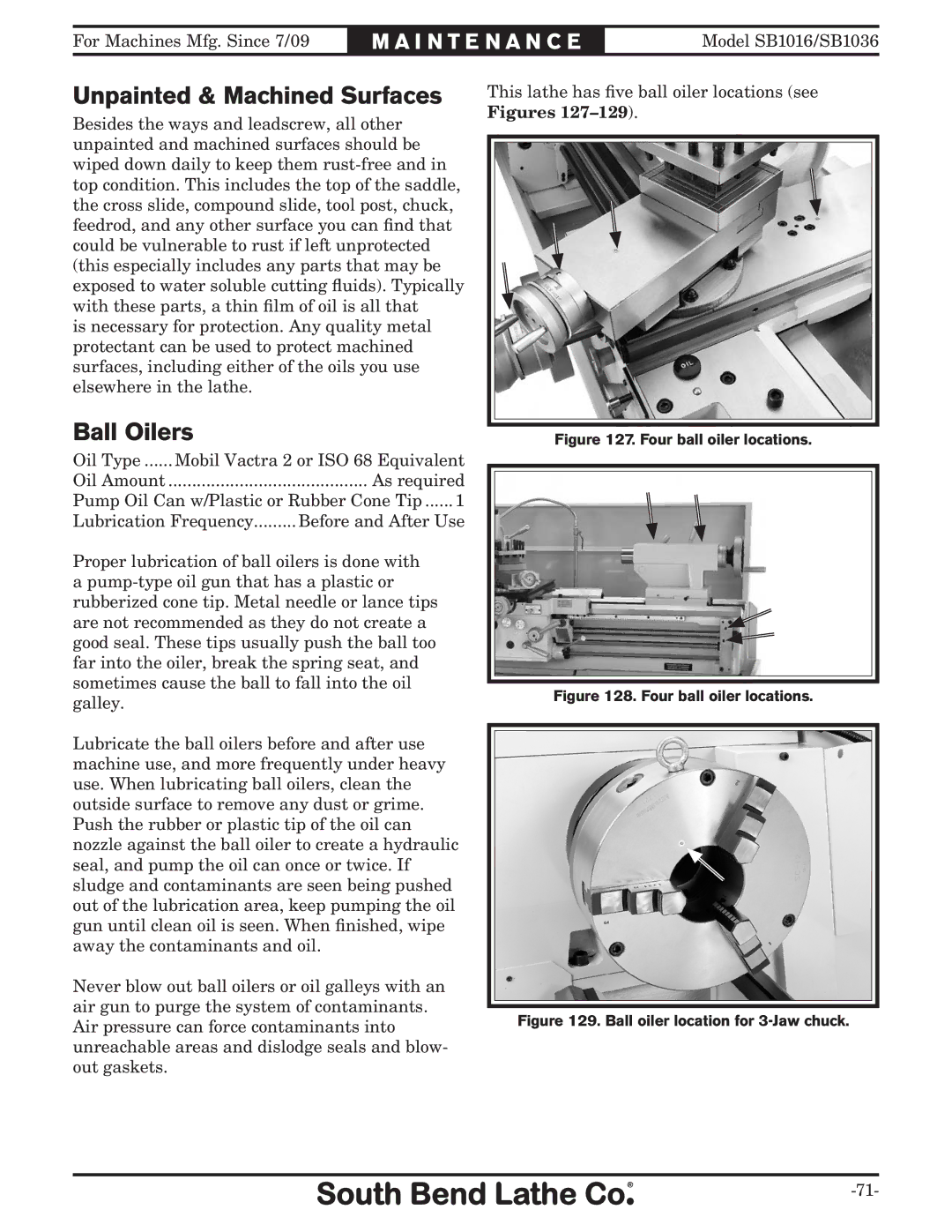

This lathe has five ball oiler locations (see Figures