For Machines Mfg. Since 7/09 | M A I N T E N A N C E | Model SB1016/SB1036 |

Cutting Fluid System

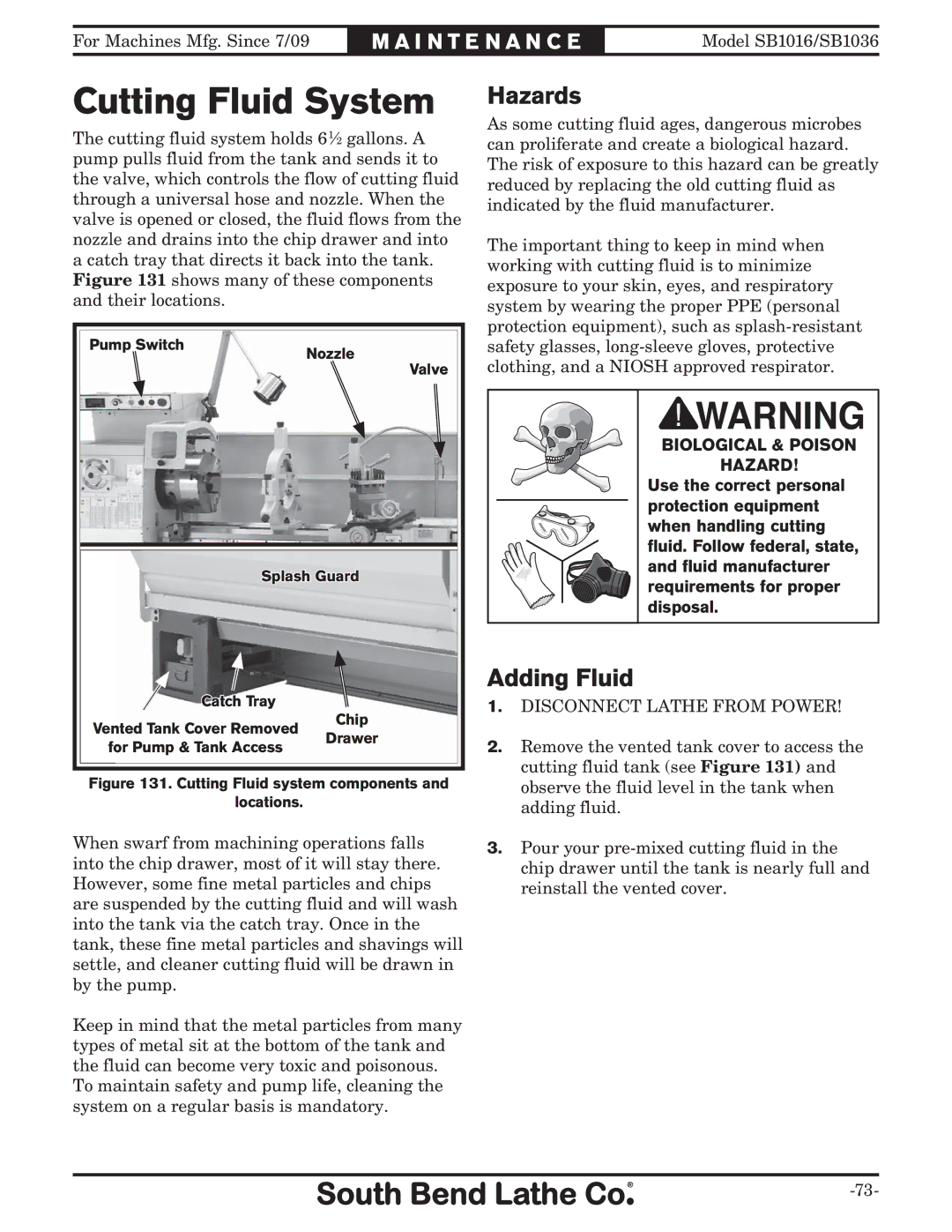

The cutting fluid system holds 61⁄2 gallons. A pump pulls fluid from the tank and sends it to the valve, which controls the flow of cutting fluid through a universal hose and nozzle. When the valve is opened or closed, the fluid flows from the nozzle and drains into the chip drawer and into a catch tray that directs it back into the tank. Figure 131 shows many of these components and their locations.

Pump Switch | Nozzle | |

| ||

| Valve | |

Splash Guard | ||

Catch Tray | Chip | |

Vented Tank Cover Removed | ||

Drawer | ||

for Pump & Tank Access | ||

| ||

Figure 131. Cutting Fluid system components and

locations.

When swarf from machining operations falls into the chip drawer, most of it will stay there. However, some fine metal particles and chips are suspended by the cutting fluid and will wash into the tank via the catch tray. Once in the tank, these fine metal particles and shavings will settle, and cleaner cutting fluid will be drawn in by the pump.

Keep in mind that the metal particles from many types of metal sit at the bottom of the tank and the fluid can become very toxic and poisonous. To maintain safety and pump life, cleaning the system on a regular basis is mandatory.

Hazards

As some cutting fluid ages, dangerous microbes can proliferate and create a biological hazard. The risk of exposure to this hazard can be greatly reduced by replacing the old cutting fluid as indicated by the fluid manufacturer.

The important thing to keep in mind when working with cutting fluid is to minimize exposure to your skin, eyes, and respiratory system by wearing the proper PPE (personal protection equipment), such as

BIOLOGICAL & POISON |

HAZARD! |

Use the correct personal |

protection equipment |

when handling cutting |

fluid. Follow federal, state, |

and fluid manufacturer |

requirements for proper |

disposal. |

Adding Fluid

1.DISCONNECT LATHE FROM POWER!

2.Remove the vented tank cover to access the cutting fluid tank (see Figure 131) and observe the fluid level in the tank when adding fluid.

3.Pour your